Introduction

The Grundfos progressive cavity pump is a versatile and efficient solution widely used in various industries for handling challenging fluids. Known for its unique design and reliable performance, this pump is essential in applications ranging from wastewater treatment to food processing.

How It Works

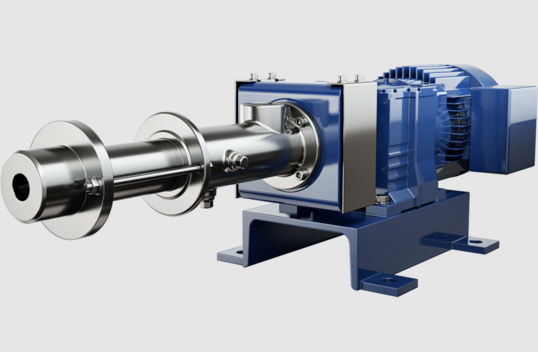

The progressive cavity pump operates using a helical rotor and a stator, which together create a series of sealed cavities. As the rotor turns, these cavities move the fluid through the pump. This design allows for smooth and consistent flow, making it ideal for viscous and shear-sensitive fluids.

Key Components

- Rotor: The helical rotor is the heart of the pump, providing the primary mechanism for fluid movement.

- Stator: The stator surrounds the rotor and is typically made of elastomeric material, facilitating the formation of cavities.

- Drive Shaft: This component connects the motor to the rotor, enabling rotation.

- Bearing Housing: Supports the rotor and helps maintain alignment during operation.

Advantages

The Grundfos progressive cavity pump offers several advantages that make it a preferred choice in many applications:

- Gentle Handling of Fluids: The non-pulsating flow ensures minimal shear stress on the fluid, preserving its integrity.

- Versatility: Capable of handling a wide range of fluids, including slurries, sludge, and viscous liquids.

- Self-Priming: The design allows for easy priming, reducing the need for additional equipment.

- Low Maintenance: Fewer moving parts translate to lower maintenance requirements and downtime.

Applications

The versatility of the Grundfos progressive cavity pump allows it to be used in various sectors, including:

- Wastewater Treatment: Efficiently pumps sludge and other wastewater materials.

- Food and Beverage Industry: Handles viscous products like sauces, creams, and pastes without compromising quality.

- Chemical Processing: Moves corrosive and aggressive fluids safely and effectively.

- Mining and Minerals: Manages thick slurries and other challenging materials.

Conclusion

The Grundfos progressive cavity pump stands out as an essential tool for industries that require reliable fluid handling solutions. Its unique design, combined with its ability to manage a variety of fluids gently and efficiently, makes it a top choice for many applications. With its low maintenance needs and versatility, the progressive cavity pump continues to play a crucial role in modern industrial processes.

People also ask

Send Your Enquiry :