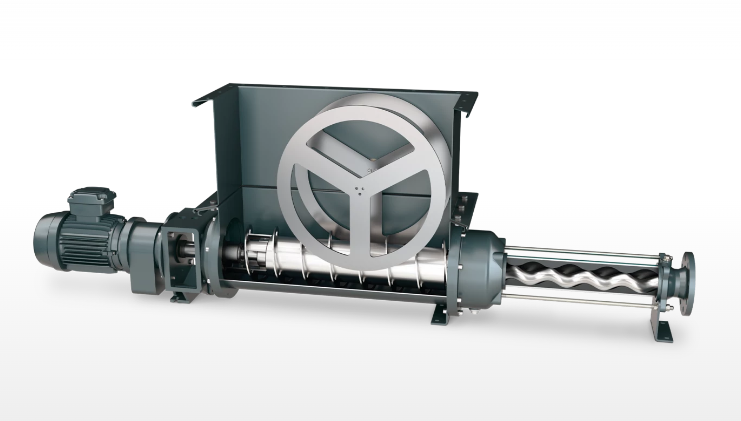

Progressive cavity pumps are widely used in various industries due to their ability to handle viscous fluids and maintain a steady flow rate. However, understanding the Net Positive Suction Head (NPSH) required for these pumps is crucial for their efficient operation and longevity. This article explores the significance of NPSH in progressive cavity pumps, the factors affecting it, and best practices for ensuring optimal performance.

Understanding NPSH

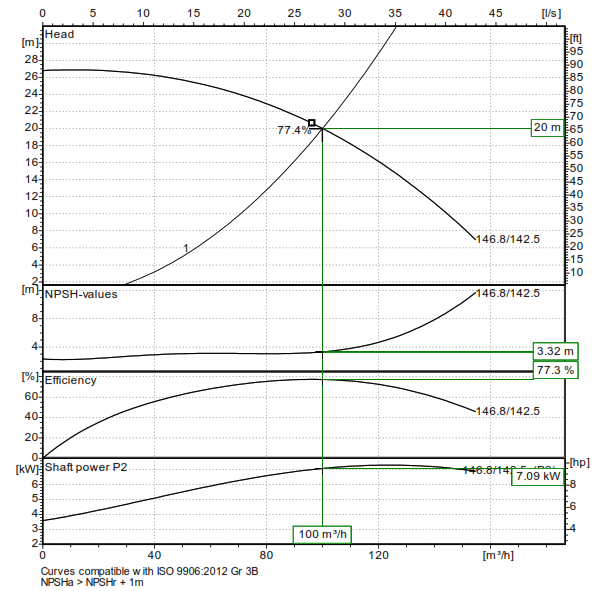

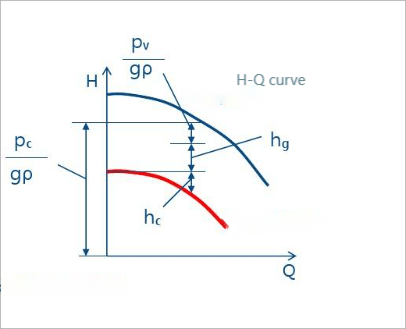

NPSH is a critical parameter that indicates the pressure available at the pump’s suction side. It is essential to ensure that the liquid entering the pump does not vaporize, as cavitation can lead to severe damage and reduced efficiency. For progressive cavity pumps, the NPSH required is influenced by several factors:

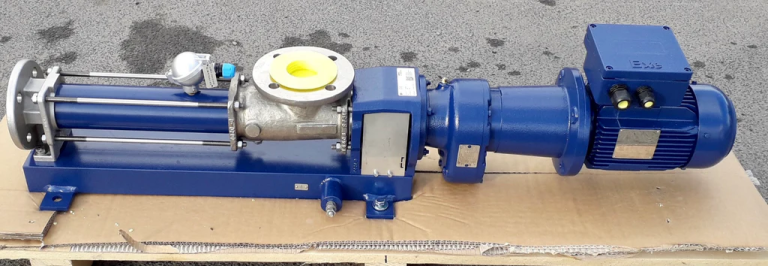

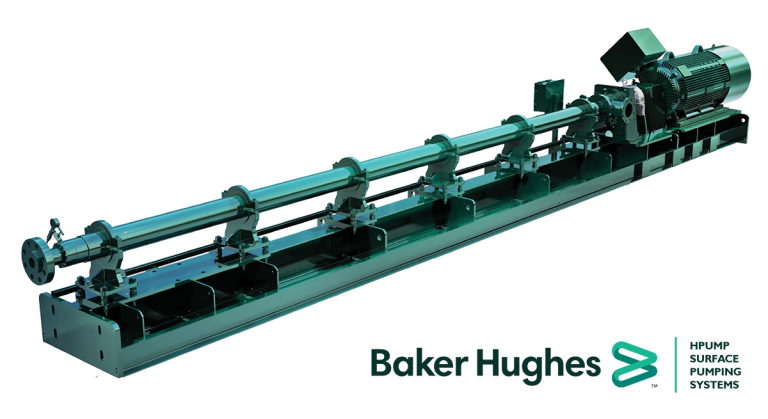

- Pump Design: The inherent design of the pump affects its NPSH requirements. Progressive cavity pumps typically require a specific NPSH to operate efficiently, which must be factored into the system design.

- Fluid Properties: The characteristics of the fluid being pumped, such as viscosity and temperature, directly impact the NPSH required. Thicker fluids may require higher NPSH levels to prevent cavitation.

- System Configuration: The layout of the piping and the height difference between the fluid source and the pump can influence the available NPSH. Proper design can mitigate potential issues related to insufficient NPSH.

Factors Affecting NPSH Requirements

Several key factors need to be considered to ensure that the NPSH required is met:

- Suction Line Design: The length and diameter of the suction line play a vital role in determining the NPSH. Longer or narrower lines can create additional resistance, necessitating a higher NPSH.

- Elevation: The vertical distance between the fluid source and the pump affects the pressure available at the pump’s suction. Pumps located above the fluid source may face challenges in meeting NPSH requirements.

- Flow Rate: Higher flow rates can lead to increased turbulence in the suction line, which may affect the NPSH. It is essential to balance the flow rate with the design of the suction system.

- Temperature: As the temperature of the fluid increases, its vapor pressure also rises, which can affect the NPSH required. Care should be taken when operating at elevated temperatures.

Best Practices for Ensuring Adequate NPSH

To ensure that progressive cavity pumps operate efficiently and without cavitation, consider the following best practices:

- Conduct a Thorough System Analysis: Before installation, analyze the entire pumping system to identify potential NPSH issues and address them in the design phase.

- Optimize Suction Line Design: Use appropriate diameters and minimize bends in the suction line to reduce resistance and ensure adequate flow to the pump.

- Monitor Operating Conditions: Regularly check the fluid properties and operating conditions to ensure they remain within the recommended ranges.

- Maintain Proper Fluid Levels: Ensure that the fluid source is adequately filled to prevent the pump from running dry, which can lead to cavitation.

In conclusion, understanding and managing the NPSH required for progressive cavity pumps is essential for their successful operation. By considering the factors that influence NPSH and implementing best practices, operators can enhance the performance and reliability of these pumps, ultimately leading to more efficient industrial processes.

People also ask

Send Your Enquiry :