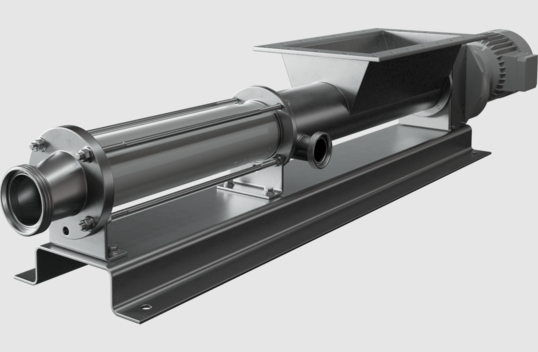

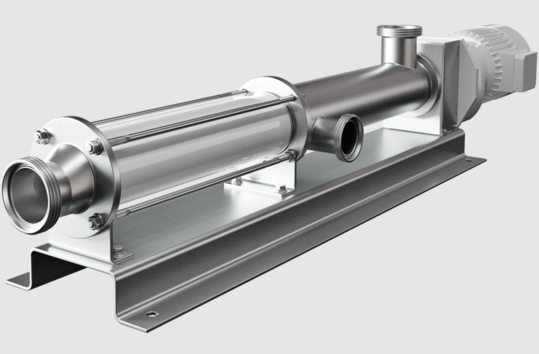

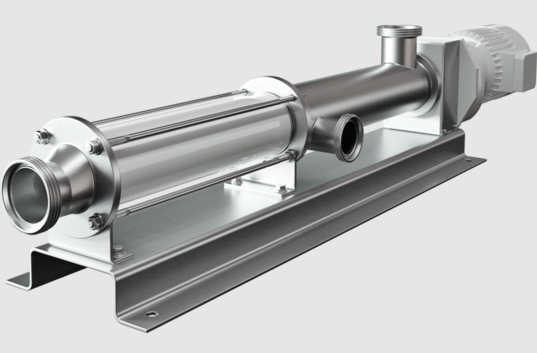

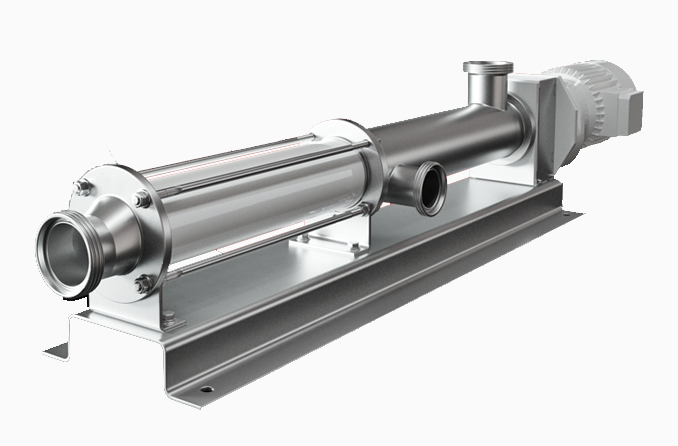

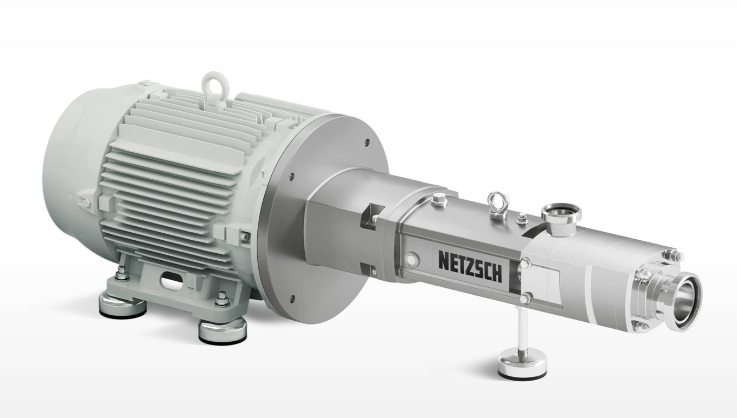

SEEPEX BTCS HOPPER PUMP IN HYGIENIC DESIGN

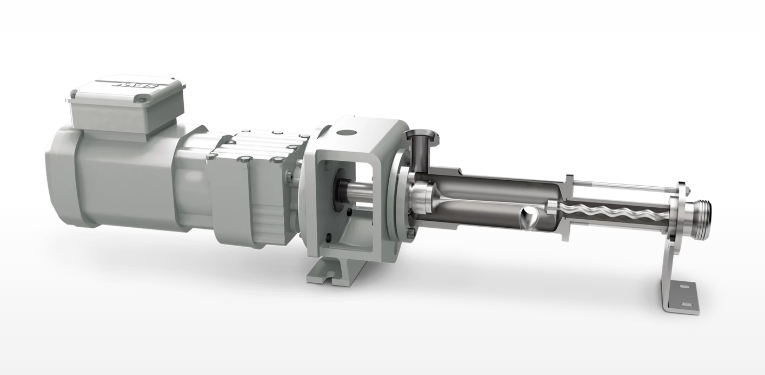

FOOD AND HYGIENIC PUMP WITH HOPPER The design of the BTCS food pump and hygienic pump from SEEPEX is characterized by a rectangular hopper with a compression zone and feed screw conveyor. This makes it particularly suited for pumping highly viscous, minimally flowable products – both with and without solids. In the hygienic design, the…