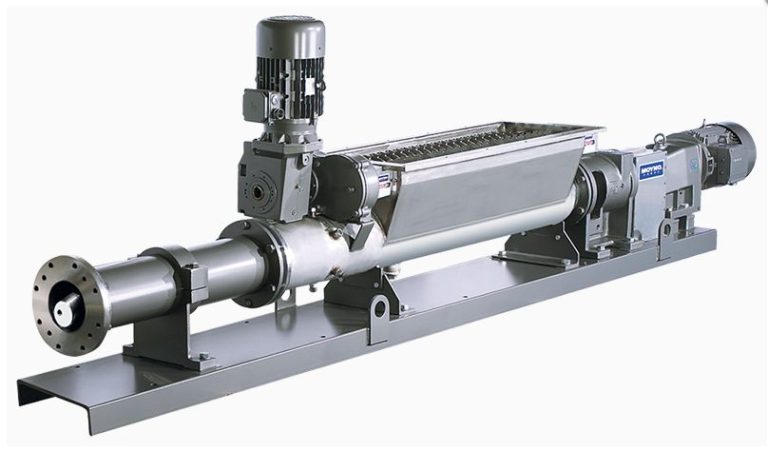

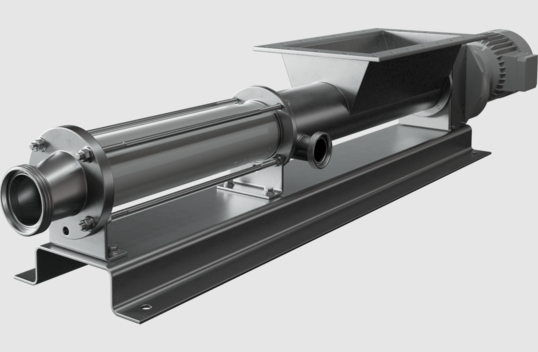

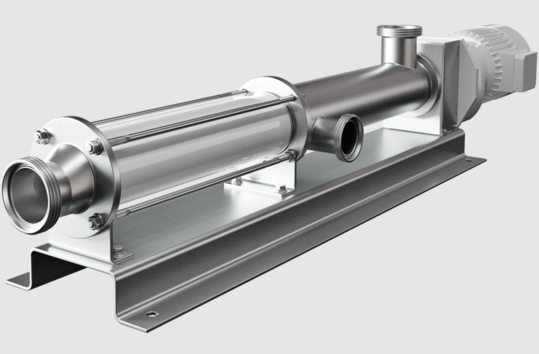

PCM DOSYS™ FOOD PISTON PUMP

PCM DOSYS™ FOOD PISTON PUMP The Dosys™ pump is made of the association of a patented rotary valve and a piston driven by a brushless electrical linear actuator. The pump is synchronized by the filling and conditioning machine, giving a very accurate on-demand dosing of non-homogeneous ingredients that may contain solid pieces. Closest to the…