-

-

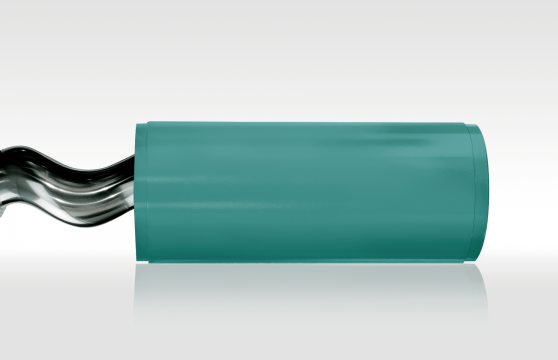

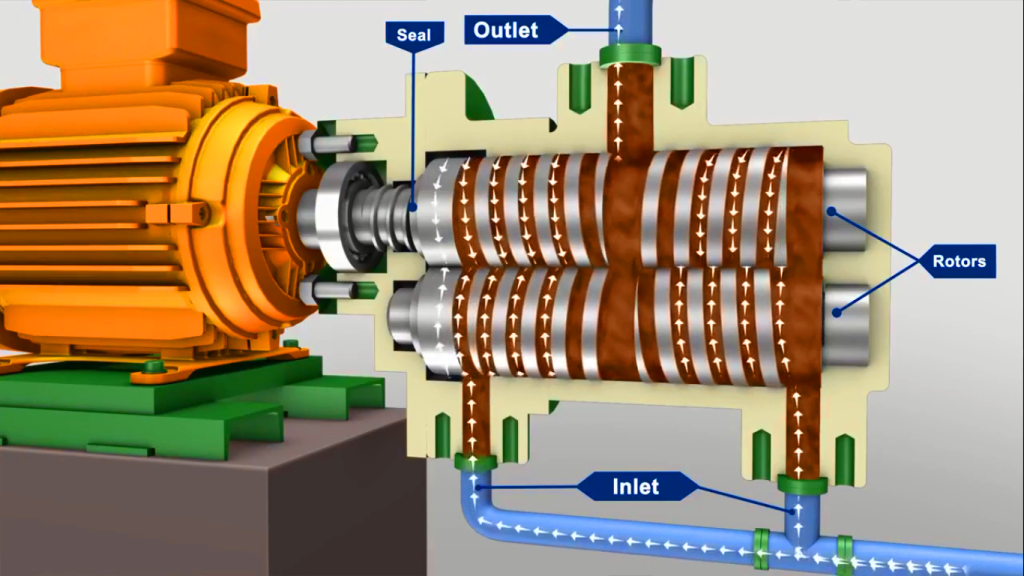

PMV Pump Stator

What is Pump Stator Stators are metal tubes with internally molded cavities of synthetic or natural rubber. The rotor seals tightly against the flexible rubber inside the stator as it rotates, forming tightly sealed cavities which carry the liquid toward the discharge port.

-

-

Pump Screw-PMV Pump

People Also Ask

-

-

-

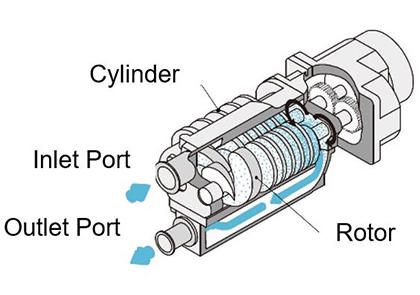

Type of Screw Pump-Pumpvv

What is a screw pump? Screw pump is a part of the dry compressed gas transfer pump series. They are positive displacement pumps that use one or more screws to move fluid or water along the screw shaft. These screws interlock to pressurize the fluid and move it into the system. These screws engage each…

-

Screw Pump-Pumpvv

The Description of Screw Pump A screw pump is a type of positive displacement pump that utilizes an intermeshing screw and housing to transfer fluids or viscous substances. The pump consists of two or more screws (also known as rotors) that rotate in opposite directions, creating chambers that trap and move the fluid along the…

-

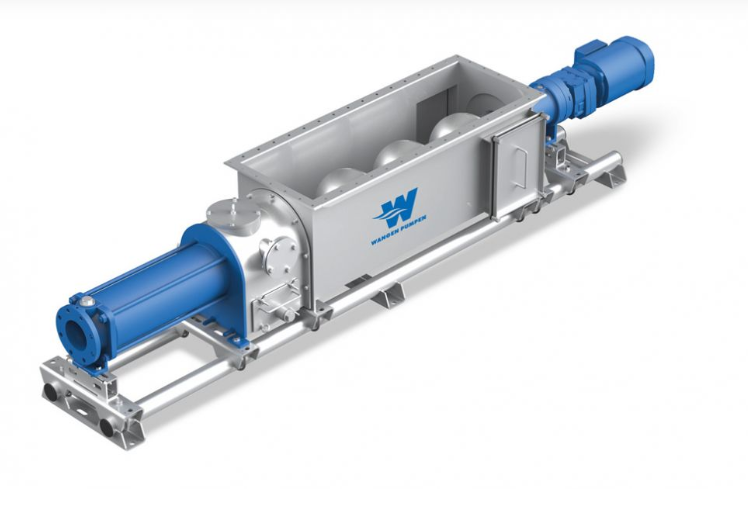

Type WANGEN BIO-MIX Hopper Feed Pump

WANGEN BIO-MIX Hopper Feed Pump WANGEN BIO-MIX pumps have been integrated for many years in the energy production process and undergone continuous further development and optimization. They are suitable for conveying maize silage, grass silage, GPS, solid manure, poultry dung, waste and co-ferments, which are mixed with liquid in the pump. Also available with WANGEN…

-

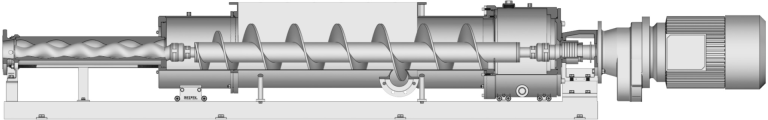

Screw Pump Diagram

Introduction to Screw Pump Diagram. A screw pump diagram is a schematic representation of the working principle and components of a screw pump. Screw pumps are positive displacement pumps that use rotating screws to move fluids or slurries through a system. They are widely used in various industries due to their ability to handle high…

screw pump types

Screw pumps are positive displacement pumps that use one or more screws to move fluids. They are widely used in various applications due to their ability to handle viscous and non-viscous fluids with high efficiency. Here’s a breakdown of the different types of screw pumps:

Types of Screw Pumps

1. Single Screw Pumps

-

- Description: Utilizes a single screw that rotates within a cylindrical casing.

-

- Applications:

-

- Handling low-viscosity fluids.

-

- Oil transfer.

-

- Applications:

-

- Advantages:

-

- Simple design and construction.

-

- Compact size.

-

- Advantages:

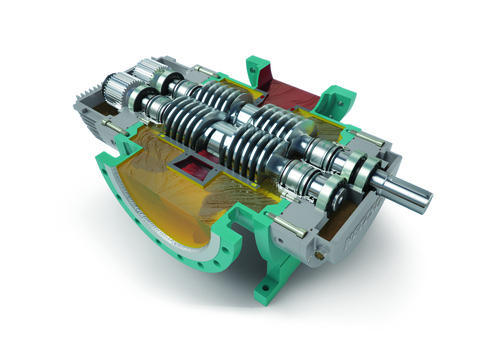

2. Twin Screw Pumps

-

- Description: Consists of two intermeshing screws that rotate in the same direction within a casing.

-

- Applications:

-

- Oil and gas industry (crude oil, diesel).

-

- Chemical processing.

-

- Applications:

-

- Advantages:

-

- High efficiency and flow rates.

-

- Smooth and pulsation-free flow.

-

- Advantages:

3. Triple Screw Pumps

-

- Description: Features three screws; typically includes two driving screws and one driven screw.

-

- Applications:

-

- Fuel transfer and lubricating oil applications.

-

- High-viscosity liquids.

-

- Applications:

-

- Advantages:

-

- Very smooth flow and low shear.

-

- Ideal for high-pressure applications.

-

- Advantages:

4. Multi-Screw Pumps

-

- Description: Incorporates more than three screws, often used in specialized applications.

-

- Applications:

-

- High-capacity industrial applications.

-

- Pumping highly viscous fluids.

-

- Applications:

-

- Advantages:

-

- High efficiency and reliability.

-

- Can handle various fluid types.

-

- Advantages:

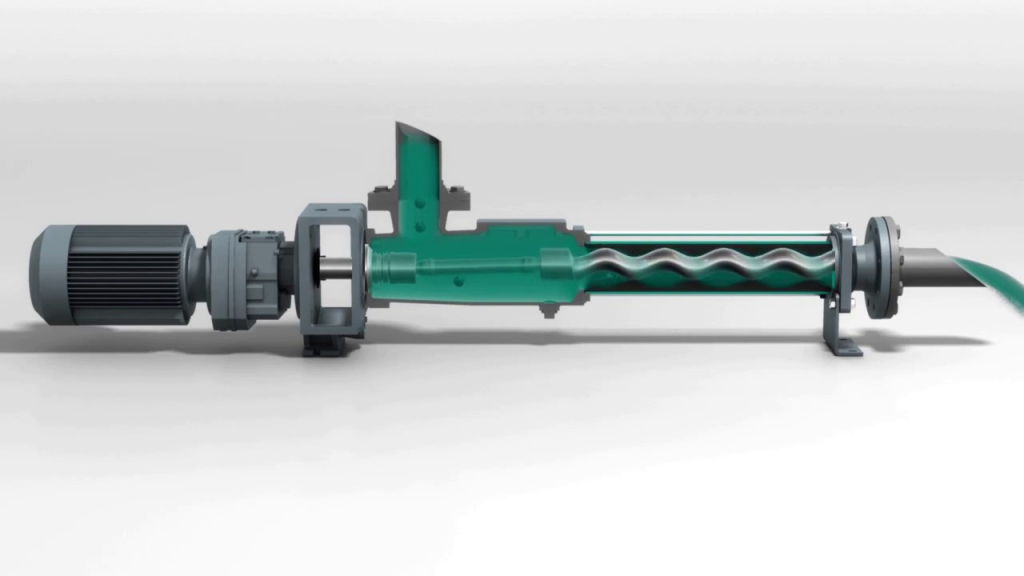

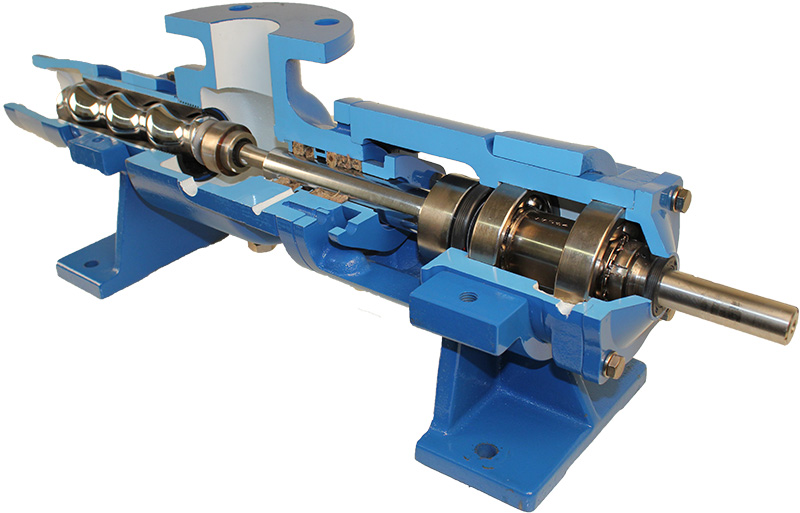

5. Progressive Cavity Pumps (Screw Type)

-

- Description: A type of screw pump that uses a rotating helical screw within a stator to create cavities that transport fluid.

-

- Applications:

-

- Wastewater treatment.

-

- Food and beverage industry.

-

- Applications:

-

- Advantages:

-

- Excellent for viscous and shear-sensitive fluids.

-

- Pulsation-free discharge.

-

- Advantages:

Summary of Applications

| Pump Type | Typical Applications | Key Advantages |

|---|---|---|

| Single Screw Pumps | Low-viscosity fluids, oil transfer | Simple design, compact size |

| Twin Screw Pumps | Oil, gas, chemical processing | High efficiency, smooth flow |

| Triple Screw Pumps | Fuel transfer, high-viscosity liquids | Very smooth flow, suitable for high pressure |

| Multi-Screw Pumps | High-capacity industrial applications | High reliability, versatile fluid handling |

| Progressive Cavity Pumps | Wastewater, food and beverage | Excellent for viscous fluids, pulsation-free |

Conclusion

Screw pumps are versatile and efficient, making them suitable for a wide range of applications across various industries. By understanding the different types of screw pumps and their specific advantages, you can make informed decisions on the best pump for your needs. Whether it’s a single screw, twin screw, or progressive cavity screw pump, each type has unique features that cater to specific fluid handling requirements.