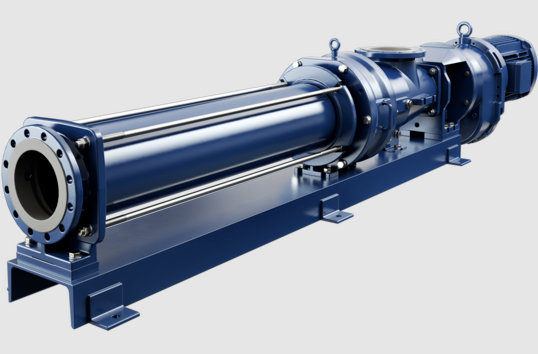

BN130-12L seepex BN

Parameters Brand: SEEPEX Performance: high pressure Weight: 760kg Pressure: 1.2Mpa Transport medium: industrial sewage Voltage: 380V Pump shaft position: horizontal Flow rate: 69m3/h Application: booster pump Impeller suction mode: single suction Lift: 120m Material: cast steel Drive mode: electric Working pressure: 1.2 Model: BN130-12 Seepex Brand Overview Founded in the last century, Seepex focuses on…