[wpseo_breadcrumb]

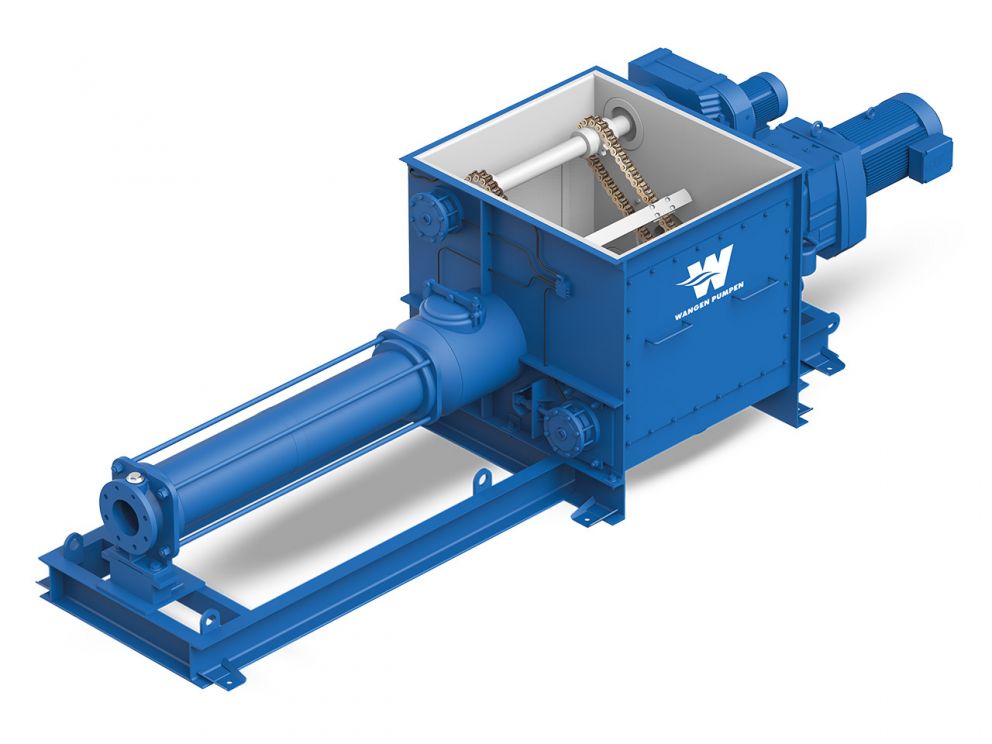

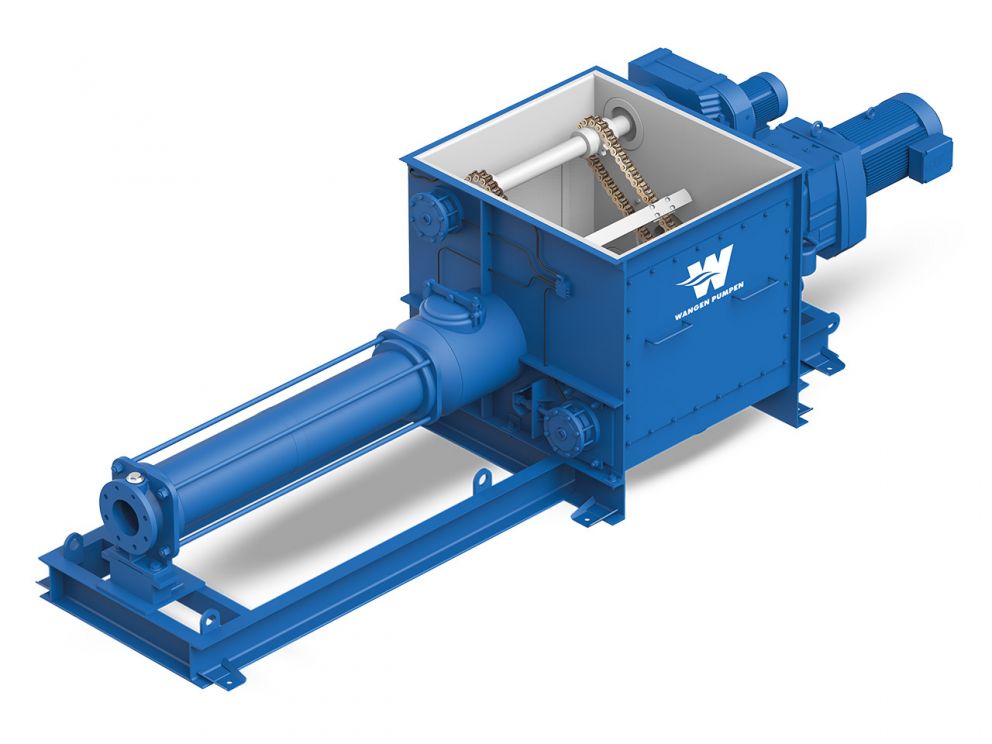

Hopper feed pump Type KL-RQ

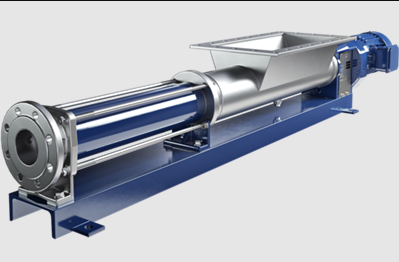

Pumps of the type WANGEN KL-RQ have a transverse feed device for integrated bridge breaking and a collecting vessel for continuous feeding. Very robust and designed for conveying dewatered sludge with a high content of dry matter (TS) ranging from 15% to 45%.

Due to their absolutely robust design, our pumps are developed for a particularly long lifespan.

The Description of WANGEN Type KL-RQ Hopper Feed Pump

The WANGEN Type KL-RQ Hopper Feed Pump is a reliable and efficient pump designed for handling viscous and abrasive media. Its unique hopper design enables easy and efficient feeding of the media, while the robust construction ensures long-lasting performance. The pump is suitable for various industries including wastewater treatment, chemical processing, and food production.

Application of WANGEN Type KL-RQ Hopper Feed Pump

The pump serie WANGEN KL-RQ convey dewatered sewage sludge. No bridge building. Very large copper / container. Abolutely robust.

- from decanters

- from chamber filter presses

- from screen belt presses

- for other feeding jobs

- to storage areas

- to silos

- to dryers

Benefits and Characteristics of KL-RQ Hopper Feed Pump

- buffer volume up to 10 m³ possible

- low Life Cycle Costs

- good pumping performance even against high pressure

- high dosing accuracy, also at low speed

- high pressure performance

- optimum service life even with difficult media

- low-pulsation, continuous conveyance independent of pressure and viscosity

- easy to maintain thanks to large cleaning openings

- excellent metering, important for dryer and incinerator operation

- unattended operation possible

- constant metering because the discontinuous input is compensated by buffer volume in the collecting container

- little space required, with large collecting container

- modular design for high flexibility and short downtimes for maintenance and repairs

- low construction with large container volume

Hopper feed pump Type KL-RQ Suitable for the following media

- sewage sludge

- refinery sludge

- dewatered sewage sludge up to 45 % dry substance

- organic sludge

Technology/Details

- stator with s-cone inlet for optimum filling of the pumping chamber

- fully developed, robust universal joint with pre-feeding screw

- enlargement possible with add-on funnel

- wear-protected, robust universal joint with feeding screw

- flexible drive selection

- robust bearing pedestal with close-coupled drive and self-centering of the drive

- collecting container optionally in three standard sizes (1m³/h – 10m³/h), special sizes on request

| Output | 0.5 up to 80 m³/h (at 25-100 rpm) |

| Dry substance Content | max. 45% |

| Free ball passage | up to 150 mm |

People Also Ask

Send Your Enquiry :