[wpseo_breadcrumb]

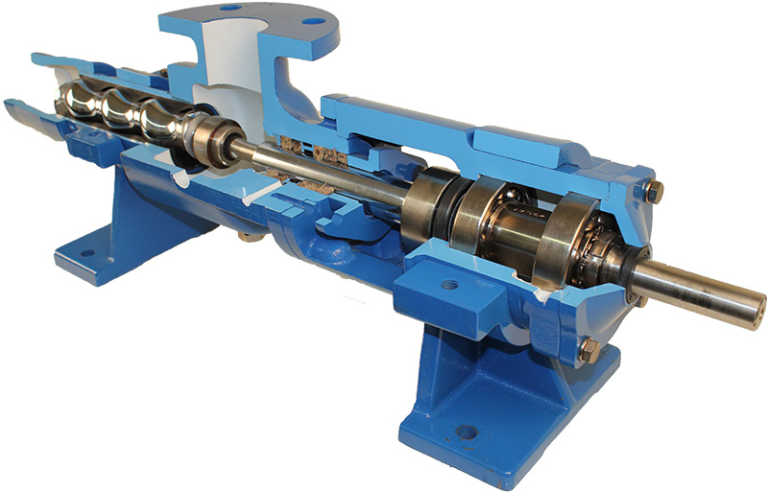

In daily machinery maintenance, the proper functioning of the water pump is crucial. Especially in large equipment, the water pump is not merely responsible for transporting water; it is a key component in ensuring the overall operation of the machinery. However, many operators often overlook a critical step when using the 800R device: filling the water pump cavity. This article will explore the potential issues arising from forgetting to fill the water pump cavity and how to avoid them.

Consequences of Forgetting to Fill

Filling the water pump cavity is not just a routine step; it directly impacts the performance of the water pump and the overall operation of the equipment. Here are some possible consequences:

- Overheating Damage: Operating the pump without sufficient water can lead to overheating, which can damage the pump body and motor.

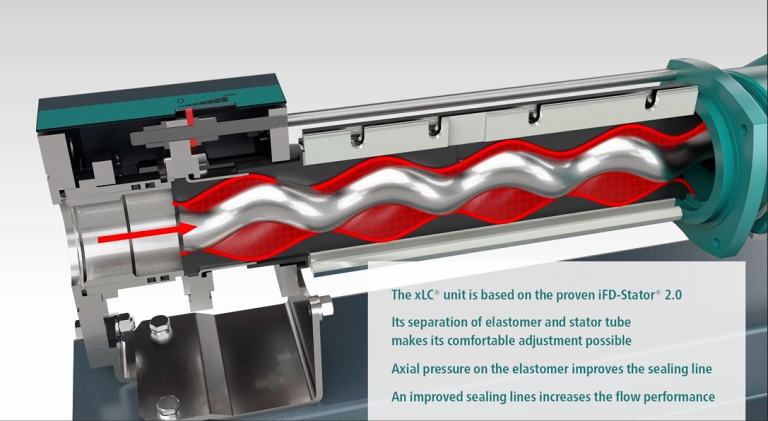

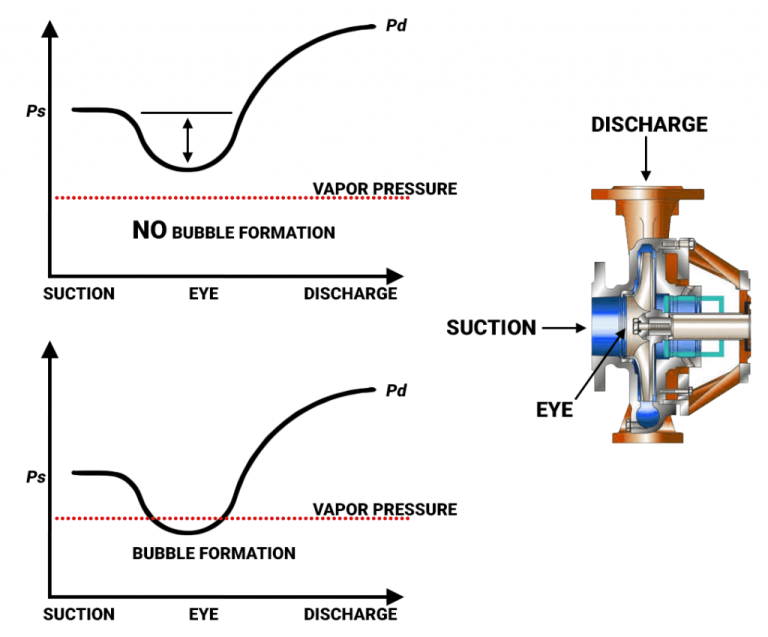

- Cavitation: A lack of water can cause cavitation, damaging the interior walls of the pump and reducing its lifespan.

- Decreased Efficiency: The working efficiency of the pump will significantly decline, affecting the performance of the entire system.

- Equipment Downtime: In severe cases, it could lead to a complete shutdown of the equipment, resulting in economic losses.

Strategies to Avoid Forgetting

To ensure the normal operation of the water pump, operators need to adopt a series of measures to prevent the oversight of filling the water pump cavity. Here are some effective strategies:

1. Establish Standard Operating Procedures

Creating detailed operating procedures can help operators clearly understand the importance of each step. Clearly mark the filling of the water pump cavity as a critical step in the process.

2. Install Warning Signs

Place prominent warning signs near the water pump to remind operators to check whether the water pump cavity has been filled before starting the equipment.

3. Conduct Regular Training

Regularly train operators on the importance of water pump maintenance. Use case studies to illustrate the serious consequences of forgetting to fill the cavity.

4. Implement Automated Monitoring Systems

Consider introducing automated monitoring systems that can real-time monitor the operating status of the water pump. If the water pump cavity is low, the system can issue alerts to prompt operators to take action.

5. Maintain Detailed Maintenance Records

Keeping detailed maintenance records can help operators understand the historical status of the equipment, enabling them to identify potential issues and avoid repeating the same mistakes.

Conclusion

In the operation of the 800R device, proper maintenance of the water pump is essential. Forgetting to fill the water pump cavity can lead not only to equipment failure but also to financial losses. Therefore, operators must prioritize this aspect by implementing strategies such as establishing standard operating procedures, installing warning signs, conducting regular training, using automated monitoring systems, and maintaining maintenance records.

In modern machinery maintenance, attention to detail is crucial. Every small step matters, and only by executing each task thoroughly can we ensure the efficient and stable operation of the equipment. It is hoped that every operator can learn from this lesson and ensure that such mistakes are not repeated in the future.

people also ask

Send Your Enquiry :