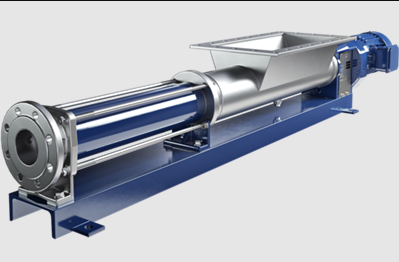

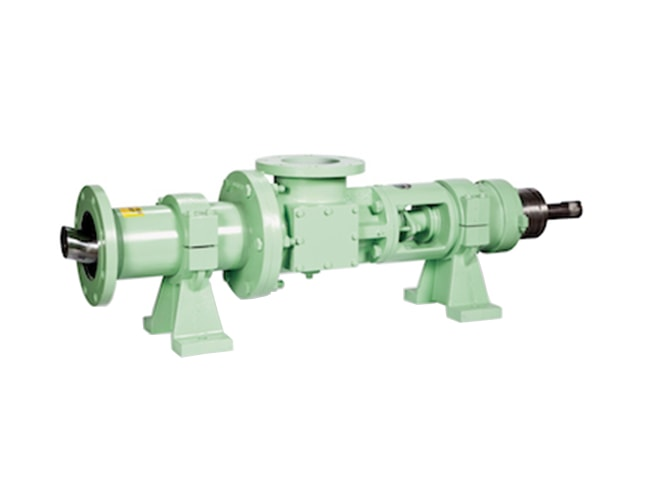

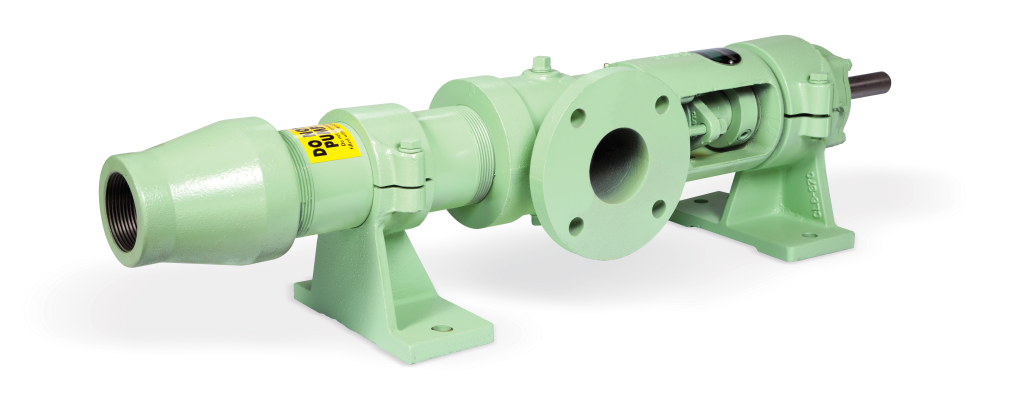

Introduction to Progressive Cavity Pumps

Progressive cavity pumps are a type of positive displacement pump widely used in various industries for their efficiency and reliability. Among these, the CL6 progressive cavity pump stands out due to its unique design and operational capabilities. This article explores the features, applications, and benefits of the CL6 progressive cavity pump.

Features of the CL6 Progressive Cavity Pump

The CL6 pump is designed with several key features that enhance its performance:

- Single Helical Rotor: The rotor’s helical design allows for smooth and continuous flow, minimizing turbulence and ensuring consistent delivery.

- Stator: The stator, typically made from elastomeric materials, provides a tight seal around the rotor, enhancing efficiency and preventing backflow.

- Versatility: The CL6 can handle a wide range of viscosities, making it suitable for different fluids, from thin liquids to thick slurries.

- Self-Priming Capability: This pump can self-prime, which simplifies installation and reduces the need for additional equipment.

Applications of the CL6 Progressive Cavity Pump

The versatility of the CL6 pump makes it suitable for various applications across multiple industries:

- Wastewater Treatment: It efficiently transfers sludge and other viscous materials in treatment plants.

- Food and Beverage: The pump is ideal for handling slurries, sauces, and other food products, ensuring hygiene and quality.

- Chemical Processing: It is commonly used for pumping chemicals, polymers, and other viscous fluids in chemical plants.

- Oil and Gas: The CL6 can transport crude oil and other hydrocarbons, making it valuable in the energy sector.

Benefits of Using the CL6 Progressive Cavity Pump

Choosing the CL6 progressive cavity pump offers numerous advantages:

- High Efficiency: The design minimizes energy consumption while maximizing flow rates, leading to cost savings over time.

- Durability: Constructed from robust materials, the CL6 is built to withstand harsh conditions and has a long operational lifespan.

- Ease of Maintenance: Routine maintenance is straightforward, and many components can be replaced without removing the entire pump from service.

- Reduced Pulsation: The continuous flow design reduces pulsation, resulting in smoother operation and less stress on piping systems.

Conclusion

The CL6 progressive cavity pump is a reliable and versatile solution for various fluid transfer applications. Its unique features, wide range of applications, and numerous benefits make it an excellent choice for industries requiring efficient and effective pumping solutions. Whether in wastewater treatment, food processing, or chemical manufacturing, the CL6 pump delivers performance and reliability, ensuring smooth operations and satisfied customers.

People also ask

Send Your Enquiry :