Introduction

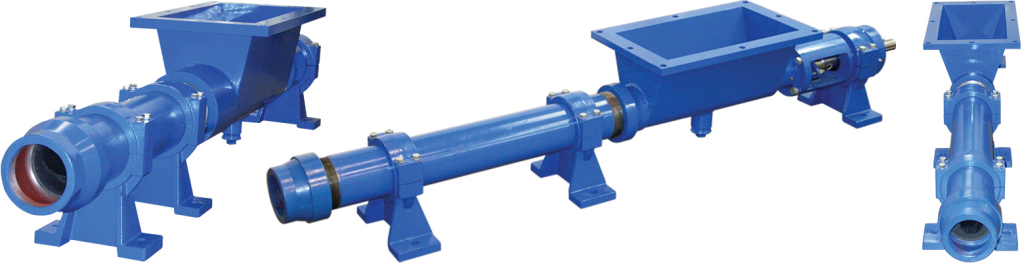

Liberty cavity pumps are specialized devices designed to handle various types of fluids, including those that are viscous, abrasive, and even shear-sensitive. Their unique design makes them a preferred choice in several industrial applications. This article explores the features, advantages, and applications of liberty cavity pumps.

Features of Liberty Cavity Pumps

Liberty cavity pumps stand out due to their innovative design and functionality. Here are some key features:

- Progressive Cavity Design: This design allows for the smooth flow of fluids through the pump, reducing the risk of shear damage to sensitive materials.

- Versatile Material Handling: These pumps can manage a wide range of fluids, from thick sludges to light oils, making them suitable for diverse industries.

- Self-Priming Capability: Liberty cavity pumps can create a vacuum to draw liquid into the system, eliminating the need for external priming devices.

- Minimal Pulsation: The progressive cavity design helps maintain a steady flow rate, minimizing pressure fluctuations and vibrations.

Advantages of Liberty Cavity Pumps

The benefits of using liberty cavity pumps are numerous, making them an attractive option for many industries. Here are some notable advantages:

- Efficiency: These pumps are designed to operate efficiently across various flow rates, which can lead to energy savings in industrial processes.

- Durability: With robust construction, liberty cavity pumps are built to withstand harsh conditions and can handle abrasive materials without significant wear.

- Low Maintenance: Their simple design means fewer moving parts, which reduces the maintenance requirements and downtime associated with more complex pumping systems.

- Adaptability: The ability to handle a range of viscosities and fluid types makes these pumps highly adaptable to different operational needs.

Applications of Liberty Cavity Pumps

Liberty cavity pumps find utility in several sectors due to their versatility. Some common applications include:

- Wastewater Treatment: They are often used to pump sludge, enabling effective waste management in treatment facilities.

- Oil and Gas Industry: These pumps can transport viscous crude oil and other fluids, facilitating extraction and processing operations.

- Food and Beverage Industry: Liberty cavity pumps are suitable for handling various food products, ensuring safe and efficient transport.

- Chemical Processing: Their ability to manage corrosive and abrasive materials makes them essential in chemical manufacturing processes.

Conclusion

Liberty cavity pumps are a vital component in many industrial applications due to their unique design and numerous advantages. Their efficiency, durability, and adaptability make them an ideal choice for handling a wide range of fluids. As industries continue to seek reliable and effective pumping solutions, liberty cavity pumps will undoubtedly remain a popular option in the market.

People also ask

Send Your Enquiry :