[wpseo_breadcrumb]

Introduction

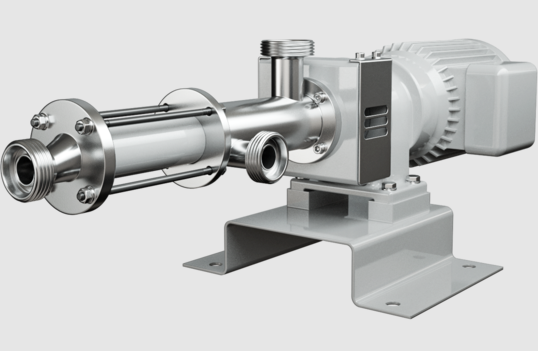

The Liberty Process Progressive Cavity Pump is a vital piece of equipment in various industrial applications. Known for its efficiency and reliability, this pump is widely used in sectors such as wastewater treatment, food processing, and chemical manufacturing. This article explores its features, benefits, and applications.

What is a Progressive Cavity Pump?

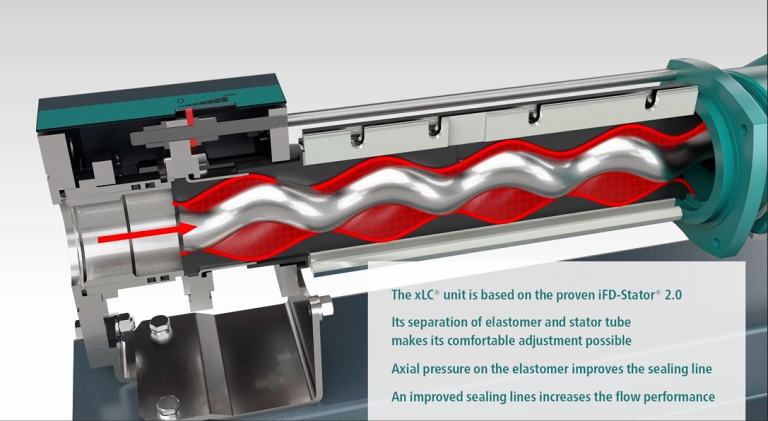

A progressive cavity pump is a type of positive displacement pump. It consists of a helical rotor that rotates within a stator, creating cavities that move fluid through the pump. This design allows for the handling of a wide range of viscosities and solids, making it suitable for challenging applications.

Key Features

The Liberty Process Progressive Cavity Pump boasts several features that contribute to its popularity:

- Versatility: Capable of handling various fluids, including slurries, viscous liquids, and shear-sensitive materials.

- Continuous Flow: Delivers a steady flow rate, reducing pulsation and providing smooth operation.

- Self-Priming: Can easily draw fluid from a lower level, making it ideal for various installations.

- Durability: Constructed from high-quality materials to withstand harsh conditions and extend the pump’s lifespan.

Benefits

Utilizing the Liberty Process Progressive Cavity Pump offers numerous advantages:

- Efficiency: Its design minimizes energy consumption while maximizing flow rate and pressure.

- Low Maintenance: Fewer moving parts lead to reduced wear and tear, resulting in lower maintenance costs.

- Adaptability: Can be customized for specific applications, including different rotor and stator materials.

- Reduced Downtime: Quick installation and maintenance processes ensure minimal disruption to operations.

Applications

The Liberty Process Progressive Cavity Pump is suitable for a variety of applications:

- Wastewater Treatment: Efficiently handles sludge and other viscous waste materials.

- Food and Beverage Industry: Used for transferring paste-like substances, ensuring product integrity.

- Chemical Processing: Handles aggressive chemicals and corrosive fluids without compromising safety.

- Oil and Gas: Effective in transporting high-viscosity fluids, including crude oil and emulsions.

Conclusion

The Liberty Process Progressive Cavity Pump stands out as a reliable and efficient solution for a wide range of industrial applications. Its unique design, coupled with its numerous benefits, makes it an essential tool in modern processing environments. As industries continue to evolve, the demand for such innovative pumping solutions will undoubtedly grow, solidifying the Liberty Process Progressive Cavity Pump’s place in the market.

People also ask

Send Your Enquiry :