[wpseo_breadcrumb]

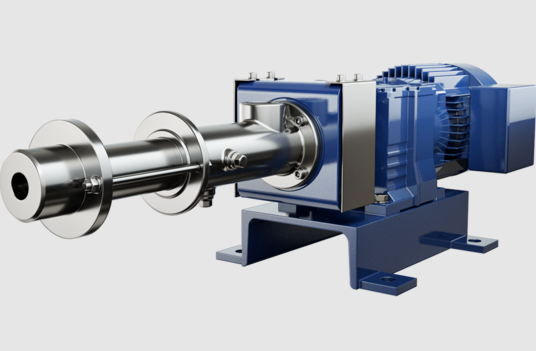

Progressive cavity pumps are essential components in various industries, known for their reliability and efficiency in handling viscous fluids. Among the notable options in this category are Liberty Process Progressive Cavity Pumps. This article explores their features, benefits, and applications.

What Are Progressive Cavity Pumps?

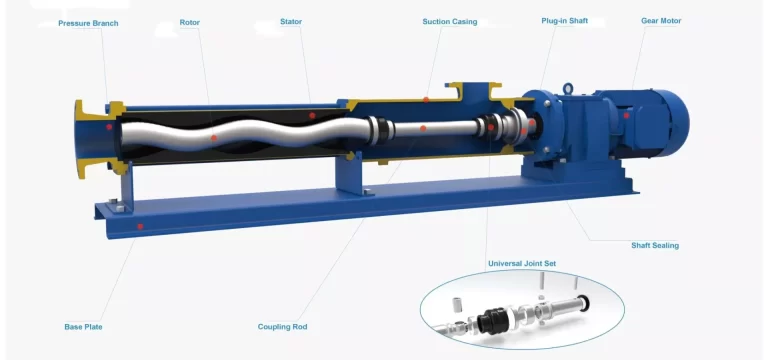

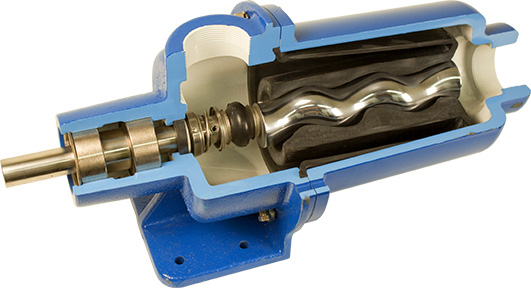

Progressive cavity pumps utilize a helical rotor that rotates within a stator, creating a series of cavities that move fluid from the inlet to the outlet. This design enables the pump to handle a wide range of fluids, including those with high viscosity or solid content.

Key Features of Liberty Process Pumps

Liberty Process Progressive Cavity Pumps are designed with several standout features that enhance their performance:

- Robust Construction: These pumps are built to withstand harsh operating conditions, making them suitable for various industrial applications.

- Gentle Handling of Fluids: The design minimizes shear stress on the fluid, making it ideal for delicate substances that require careful handling.

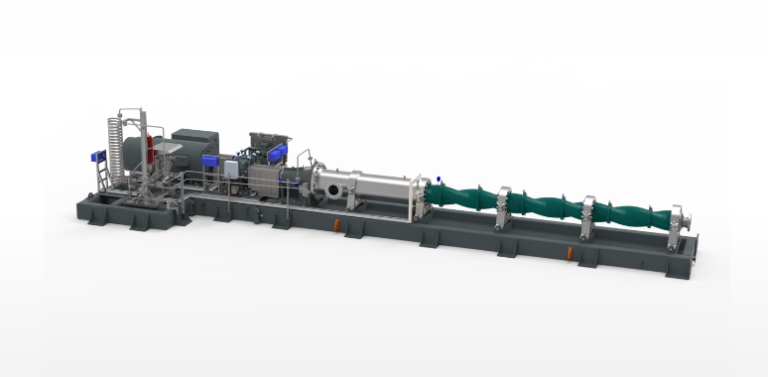

- Versatile Applications: From wastewater treatment to food processing, these pumps can handle a diverse range of materials, including slurries and pastes.

- Easy Maintenance: Liberty pumps are designed for straightforward maintenance, reducing downtime and ensuring continuous operation.

Benefits of Using Liberty Progressive Cavity Pumps

The advantages of using Liberty Process Progressive Cavity Pumps are numerous:

- High Efficiency: These pumps provide consistent flow rates, which helps in maintaining process stability and efficiency.

- Cost-Effective Operation: Their durability and low maintenance requirements contribute to lower operational costs over time.

- Adaptability: The pumps can be customized to meet specific application needs, ensuring optimal performance in various environments.

- Environmental Safety: With a design that minimizes leaks and spills, these pumps contribute to safer operations and reduced environmental impact.

Applications of Liberty Process Pumps

Liberty Process Progressive Cavity Pumps find applications across multiple sectors, including:

- Chemical Processing: Ideal for transferring corrosive or viscous chemicals with precision.

- Food and Beverage: Capable of handling various food products, ensuring hygiene and quality.

- Oil and Gas: Efficiently moving crude oil and other hydrocarbons, even in challenging conditions.

- Pharmaceuticals: Essential for the accurate transfer of sensitive materials, ensuring compliance with industry standards.

Conclusion

Liberty Process Progressive Cavity Pumps represent a reliable solution for industries requiring efficient and flexible fluid handling. Their robust design, coupled with numerous benefits, makes them a preferred choice for many applications. By investing in these pumps, businesses can enhance their operational efficiency while ensuring the safety and quality of their processes.

People also ask

Send Your Enquiry :