[wpseo_breadcrumb]

Introduction

Drum pumps play a crucial role in various industries, facilitating the transfer of liquids from drums or containers to other systems. Among the different types of drum pumps, the progressive cavity pump stands out due to its unique design and efficiency. This article explores the features, advantages, and applications of progressive cavity drum pumps, along with insights into selecting the right distributor.

What is a Progressive Cavity Pump?

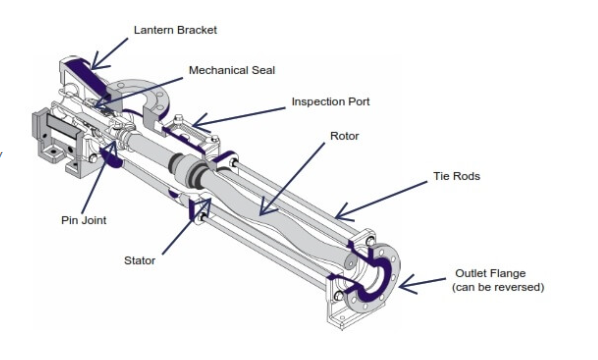

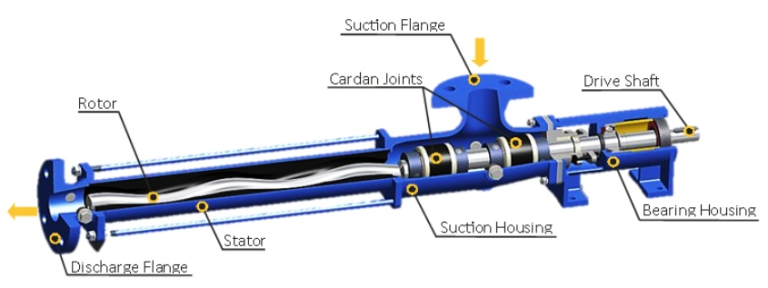

A progressive cavity pump consists of a helical rotor and a stator, which work together to create a continuous flow of liquid. As the rotor turns, it moves the liquid through the stator, ensuring a smooth and steady transfer. This design allows for handling a wide range of viscosities, making it suitable for various applications.

Advantages of Progressive Cavity Drum Pumps

- Versatile Handling

Progressive cavity pumps can handle both low and high-viscosity fluids, including slurries and thick liquids. This versatility makes them ideal for industries such as food processing, chemical manufacturing, and wastewater treatment. - Consistent Flow Rate

One of the standout features of these pumps is their ability to provide a constant flow rate regardless of the pressure. This consistency is vital for processes that require precise liquid transfer. - Gentle Handling of Fluids

The design of progressive cavity pumps minimizes turbulence, making them suitable for shear-sensitive liquids. This characteristic is particularly important in the food and pharmaceutical sectors, where preserving the integrity of the product is essential. - Durability and Reliability

Made from robust materials, progressive cavity pumps are designed to withstand harsh operating conditions. Their longevity and reliability reduce the need for frequent replacements, resulting in lower operational costs.

Applications of Progressive Cavity Pumps

- Food and Beverage Industry

Used for transferring sauces, creams, and other viscous liquids without damaging their structure. - Chemical Industry

Ideal for pumping corrosive and viscous chemicals, ensuring safety and efficiency in the process. - Pharmaceuticals

Essential for handling sensitive compounds where contamination and shear are concerns. - Wastewater Treatment

Effective in managing sludge and other thick liquids, helping to maintain a smooth treatment process.

Choosing the Right Drum Pump Distributor

Selecting the right distributor for progressive cavity drum pumps is crucial for ensuring quality and support. Here are some factors to consider:

- Experience and Reputation

Look for distributors with a strong track record and positive customer feedback. Experienced distributors are more likely to offer reliable products and services. - Product Range

A wide selection of pumps ensures that you can find the right model for your specific needs. Distributors should offer various brands and configurations. - Technical Support

Choose a distributor that provides comprehensive technical support, including installation, maintenance, and troubleshooting assistance. - After-Sales Service

Good after-sales service is vital for long-term satisfaction. Ensure the distributor offers warranties and replacement parts.

Conclusion

Progressive cavity drum pumps are invaluable in numerous industries due to their versatility, reliability, and efficiency. By understanding their benefits and applications, businesses can make informed decisions when selecting the right pump and distributor. Investing in quality equipment and support will ultimately lead to improved operational performance and satisfaction.

Send Your Enquiry :