Parameters

- Brand:SEEPEX

- Pressure:1.2Mpa

- Pump shaft position:Horizontal

- Impeller suction mode:Single suction

- Drive mode:Electric

- Performance:High pressure

- Conveying medium:Sewage pump, impurity pump

- Scope of application:SEEPEX screw pump

- Flow rate:20m3/h

- Head:120m

- Number of impellers:1

- Working pressure:1.1

- Weight:96kg

- Voltage:380V

- Available for sale:National

- Purpose:Sewage pump

- Material:Cast iron

- Model:BN35-12

Introduction

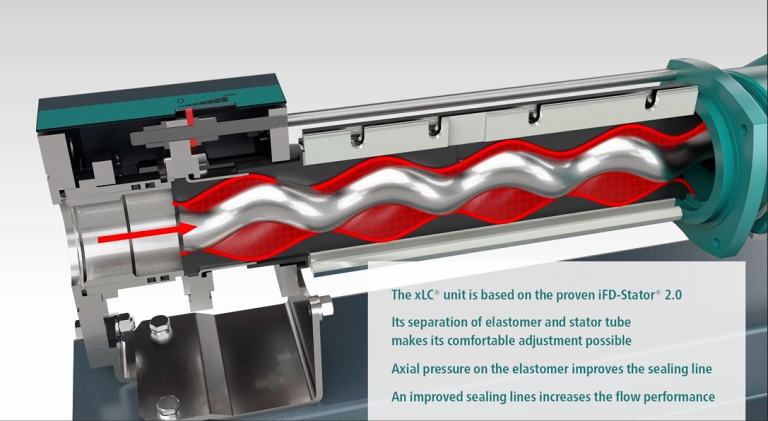

The seepex BN35-12 rotor is made of high-quality stainless steel, which has excellent wear resistance and corrosion resistance. The seepex BN35-12 stator is made of high-molecular polymer material, which has wear resistance, corrosion resistance and good sealing performance.

Application areas

seepex BN35-12 is a medium-sized single screw pump, which is widely used in many industries such as chemical, food, and environmental protection. As one of the star products of seepex, it is known for its excellent wear resistance, high efficiency and energy saving, and long service life. In the field of renewable energy, seepex BN35-12 pumps are mainly used to transport various slurries and muds, such as biomass slurry in biomass power plants, or silicon mud in solar cell manufacturers.

Taking biomass energy as an example, biomass power plants usually use a continuous feeding system for biomass materials, and need to transport various raw materials such as straw and wood chips to the furnace for combustion and power generation. In this process, the seepex BN35-12 pump is required to exert its excellent conveying capacity. Due to the characteristics of biomass raw materials such as fibrous and high water content, the wear resistance and self-priming performance of the pump are very high. With its unique single screw design, seepex BN35-12 can easily cope with these challenges and reliably transport various biomass raw materials to the boiler. At the same time, this pump uses advanced energy recovery technology, which can significantly reduce power consumption during operation and save a lot of operating costs for biomass power plants.

Compared with biomass power generation, solar cell manufacturing also requires a large number of pump equipment. In the production process of solar cells, silicon slurry needs to be transported to subsequent cutting, cleaning and other processes. This places high demands on the pump’s conveying performance, wear resistance and cleanliness. With its closed design, the seepex BN35-12 pump can reliably complete the task of conveying silicon slurry while ensuring cleanliness. In addition, this pump also has the characteristics of self-adjusting flow, which can automatically adjust the output according to production needs, further improving production efficiency.

Flexibility of use

In addition to excellent performance and durability, another major advantage of the seepex BN35-12 is its flexibility of use. As a medium-sized screw pump, it is between small and large in terms of size and power, and can meet the needs of various occasions.

At the same time, the seepex BN35-12 also has a wide range of material options. Whether it is carbon steel, stainless steel or special plastics, it can be configured according to the specific application environment. This enables it to adapt to various corrosive media and perform well in harsh environments such as chemical and pharmaceutical industries.

In addition, seepex BN35-12 also supports multiple drive modes, and can use different power sources such as electric motors, diesel engines or hydraulic motors. This flexibility greatly expands its application range. Whether it is a fixed workshop or a mobile construction site, seepex BN35-12 can provide a suitable solution.

people also ask

Send Your Enquiry :