[wpseo_breadcrumb]

The Description of NETZSCH PUMP

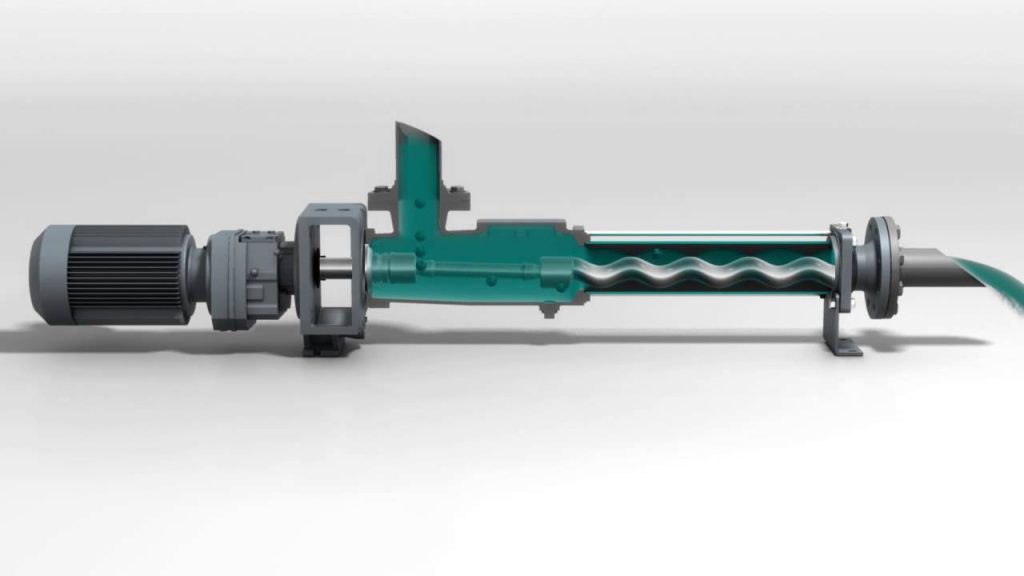

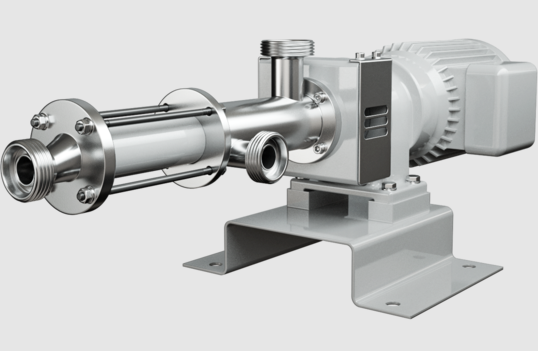

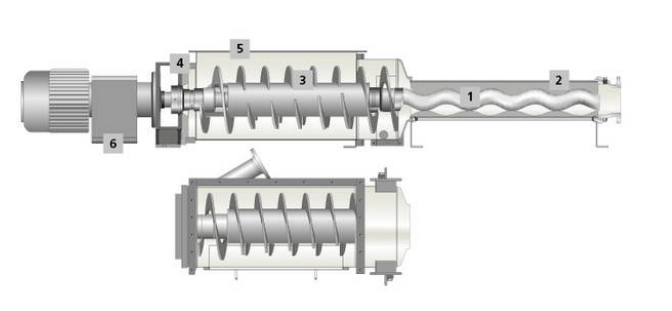

Netzsch pump is a type of positive displacement pump that utilizes a progressive cavity design to handle difficult-to-pump fluids with high viscosity, abrasiveness, and shear sensitivity. This type of pump is designed with a helical rotor and stator that create a series of sealed cavities to move fluid through the system.

The Applications of NETZSCH PUMP

Netzsch pumps are widely used in a variety of industries including chemical, food and beverage, oil and gas, and wastewater treatment. They are ideal for handling fluids that pose challenges for other types of pumps, such as high viscosity liquids, abrasive slurries, and shear-sensitive materials. Some specific applications include transferring adhesives, resins, and polymers, pumping emulsions, suspensions, and sludges, and metering chemicals and additives.

The Features of NETZSCH PUMP

Netzsch pumps offer several key features that make them well-suited for challenging fluid handling applications. These features include a self-priming design, low pulsation flow, high suction lift, the ability to handle abrasive and corrosive materials, gentle pumping action, and easy maintenance. The self-priming design allows for efficient startup without the need for external priming, while the low pulsation flow helps to minimize shear forces on sensitive materials. The high suction lift capability enables the pump to draw fluid from deep wells or tanks, and the ability to handle abrasive and corrosive materials makes it a versatile choice for many different applications. Additionally, the gentle pumping action minimizes damage to the fluid and equipment, while the simple design allows for easy maintenance and repair.

Conclusion of NETZSCH PUMP

NETZSCH PUMP is a reliable and versatile choice for challenging fluid handling applications that require gentle pumping action and precise metering capabilities. With its unique progressive cavity design and robust set of features, it is well-suited for a wide range of industries and applications.