Introduction

Progressive cavity pumps are essential devices widely used in various industrial sectors. Their unique structure and operating principle enable them to effectively transport viscous fluids and those containing solid particles. This article explores the basic construction, working principle, key features, and application areas of progressive cavity pumps.

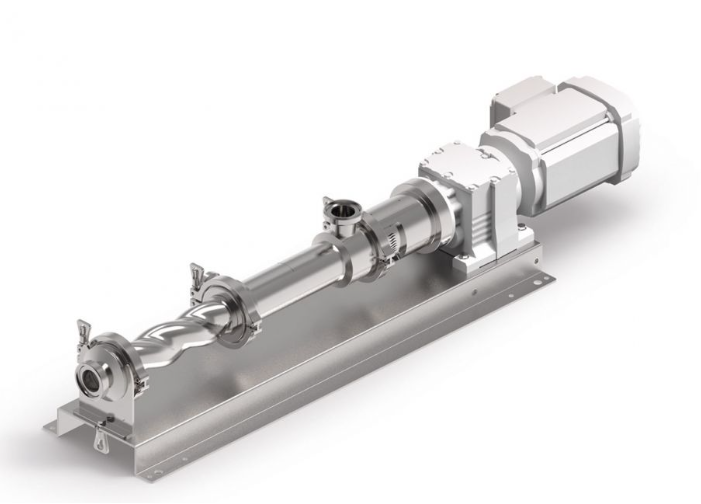

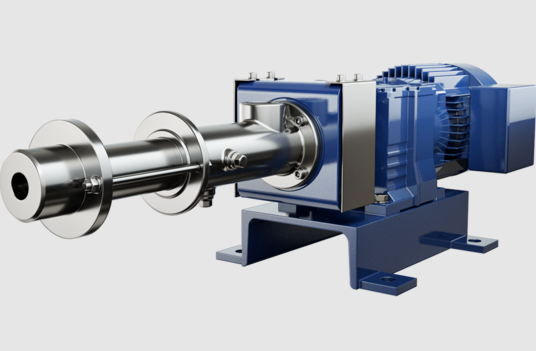

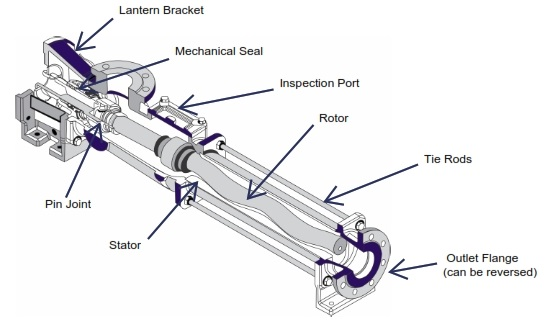

Basic Construction of Progressive Cavity Pumps

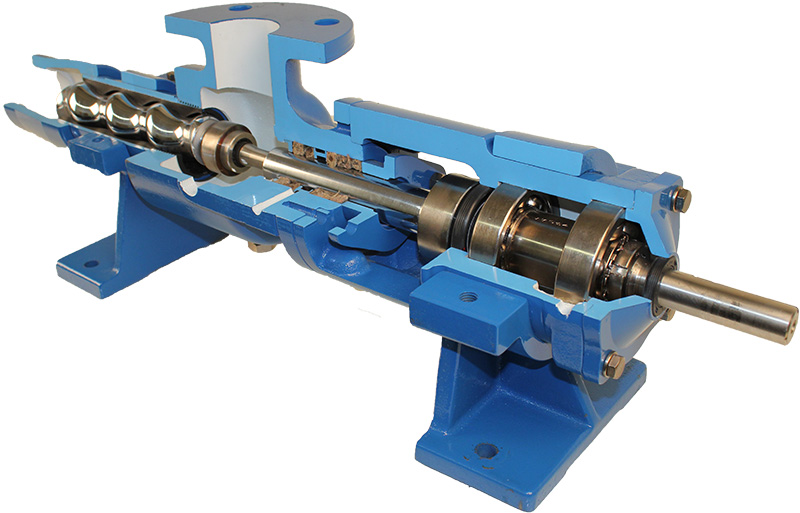

The primary components of a progressive cavity pump include:

- Pump Housing: The outer shell that provides structural support.

- Rotor: Typically helical in shape, it creates continuous cavities as it rotates within the pump housing.

- Stator: Made of elastic material, it fits with the rotor to form seals, preventing fluid leakage.

- Drive Mechanism: Provides the necessary power to rotate the rotor, thereby moving the fluid.

Working Principle

The working principle of a progressive cavity pump is relatively straightforward. As the rotor spins within the pump housing, it draws fluid in through the inlet and pushes it toward the outlet via the helical cavities. Due to the sealing between the rotor and stator, the fluid moves continuously without forming bubbles or pulsations. This stable flow output makes progressive cavity pumps highly effective in various applications.

Key Features of Progressive Cavity Pumps

Progressive cavity pumps possess several notable characteristics:

- Versatility: Capable of handling a wide range of viscous, corrosive, or solid-containing fluids.

- Stable Flow: Provides a consistent flow rate, suitable for applications requiring high precision.

- Low Shear Force: Minimal shear force on the fluid, making them ideal for transporting shear-sensitive substances, such as certain foods and pharmaceuticals.

- Self-Priming Ability: Excellent self-priming capabilities, suitable for use in low liquid level conditions.

- Easy Maintenance: Simple structure allows for easier maintenance and component replacement.

Application Areas

Progressive cavity pumps find applications across multiple industries, including:

- Oil and Gas: Used for transporting heavy oil, wastewater, and various chemicals.

- Food and Beverage: Responsible for moving viscous liquids like fruit pulp and syrups in food processing.

- Pharmaceutical Industry: Transporting drugs and raw materials while ensuring contamination-free and gentle handling.

- Environmental Sector: Employed in wastewater treatment and the transport of chemical waste.

- Construction Industry: Plays a crucial role in concrete pouring and the transportation of other construction materials.

Conclusion

Progressive cavity pumps, with their unique design and superior performance, are extensively used in a variety of fields. As industrial technology continues to advance, the design and manufacturing of progressive cavity pumps are also evolving, promising greater functionality in more complex fluid transport scenarios. A deeper understanding of progressive cavity pumps will aid in selecting and applying this important equipment, ensuring efficient fluid transport solutions across various industries.

people also ask

Send Your Enquiry :