[wpseo_breadcrumb]

In the industrial and engineering sectors, progressive cavity pumps are widely recognized for their unique operating principles and broad applications. This article will explore the structure, working mechanism, advantages and disadvantages, and applications of progressive cavity pumps.

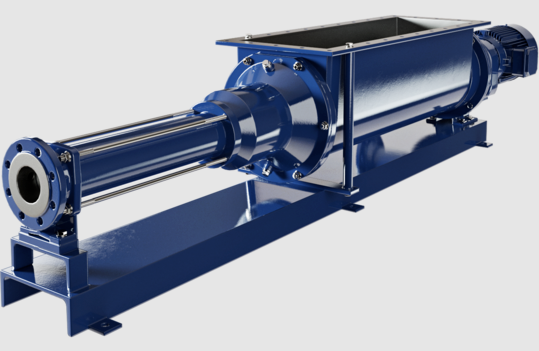

Basic Structure of a Progressive Cavity Pump

A progressive cavity pump mainly consists of the following components:

- Rotor: Typically a helical component that is responsible for moving the fluid.

- Stator: A corresponding helical component that encloses the rotor. The internal shape of the stator matches the rotor, forming multiple progressively smaller cavities.

- Drive Mechanism: An electric motor or other power source that rotates the rotor.

- Inlet and Outlet: The fluid enters through the pump’s inlet and is discharged through the outlet.

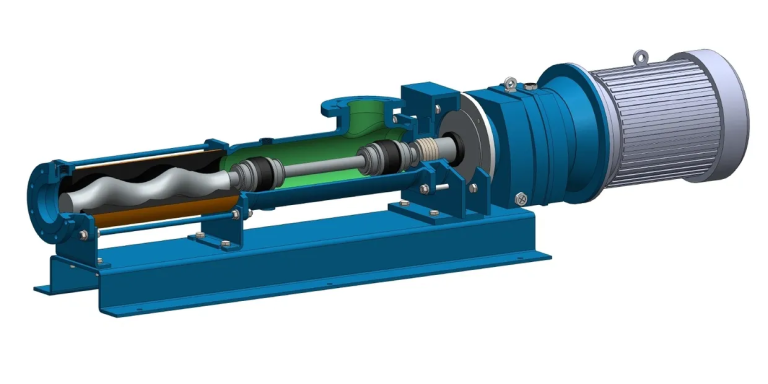

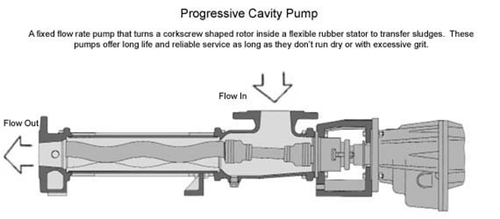

Working Principle

The working principle of a progressive cavity pump is relatively simple yet effective. The rotor rotates within the stator, forming multiple sealed cavities. As the rotor turns, the fluid is gradually pushed through the cavities, resulting in continuous flow.

Main Steps:

- Fluid Entry: Fluid enters through the pump’s inlet, filling the cavities between the rotor and the stator.

- Rotation Push: As the rotor rotates, the fluid in the cavities is gradually pushed toward the outlet.

- Fluid Discharge: Finally, the fluid is expelled through the pump’s outlet, completing the process.

Advantages and Disadvantages

Advantages:

- Stable Flow Rate: Progressive cavity pumps can provide a stable flow rate, suitable for applications with strict flow requirements.

- High Adaptability: Capable of handling fluids with various viscosities, including high-viscosity and solid-containing fluids.

- Low Pulsation: Due to its design, the pump exhibits minimal flow pulsation, helping to protect downstream equipment.

- Self-Priming Capability: Under certain conditions, the pump can self-prime, making it easier to install and use.

Disadvantages:

- Wear Issues: Due to friction between the rotor and stator, wear may occur over time, necessitating regular maintenance and replacement.

- Higher Cost: Compared to traditional pumps, the manufacturing and maintenance costs of progressive cavity pumps may be higher.

- Sensitivity to Speed: The pump’s performance is closely related to its rotational speed; both excessive and insufficient speeds can affect flow and pressure.

Application Areas

Progressive cavity pumps are widely used in various industries due to their unique performance characteristics, including:

- Oil and Gas: Used to transport crude oil, natural gas, and their derivatives, particularly under low-pressure and high-viscosity conditions.

- Food and Beverage: In food processing, they are suitable for transporting syrups, sauces, and other high-viscosity liquids.

- Chemical Industry: Used to handle a variety of chemicals, including corrosive and high-viscosity liquids.

- Wastewater Treatment: Employed in the transportation of fluids containing solid particles during wastewater and sewage treatment processes.

Future Development Trends

With ongoing technological advancements, the design and materials of progressive cavity pumps are continually improving. Future developments may lead to more wear-resistant and lightweight materials, extending the pump’s service life. Additionally, the integration of smart control systems will enhance the efficiency and automation of pump operations.

People also ask

Send Your Enquiry :