[wpseo_breadcrumb]

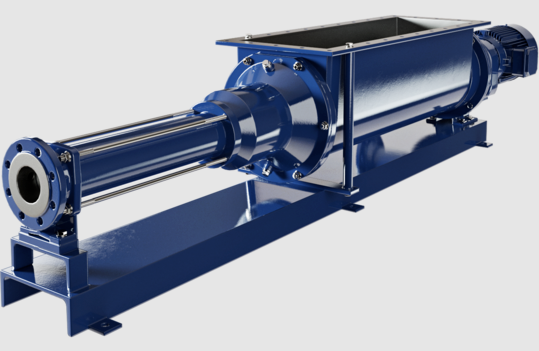

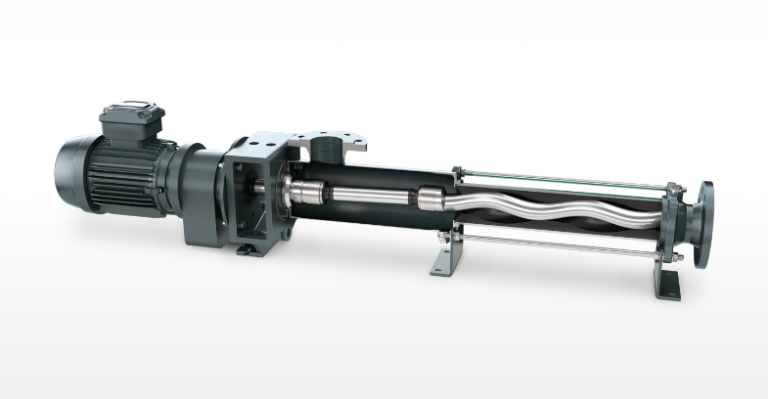

Overview of Progressive Cavity Pumps

Progressive cavity pumps are designed to transport viscous fluids. Their structure allows for the formation of multiple cavities within the pump body, enabling continuous fluid transfer. Key characteristics of these pumps include:

- Efficient Transfer: Suitable for a variety of viscous liquids.

- Low Pulsation: Maintains stable flow rates.

- Wide Adaptability: Applicable across different industrial sectors.

Importance of the Aftermarket

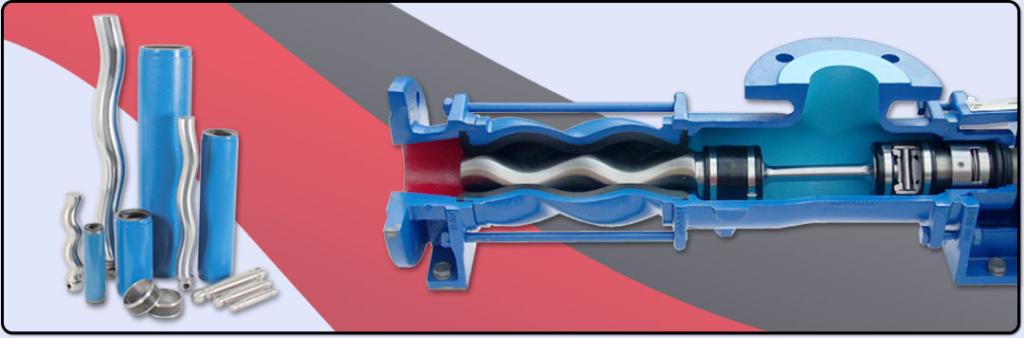

The aftermarket plays a crucial role in the lifecycle of progressive cavity pumps. Its importance can be highlighted in several areas:

- Parts Supply: As pumps are used, wear and tear on components is inevitable. The aftermarket provides a wide range of parts to ensure the pumps operate effectively.

- Technical Support: Aftermarket service teams typically possess specialized knowledge, capable of providing effective troubleshooting and maintenance advice.

- Equipment Upgrades: With technological advancements, the aftermarket can offer the latest upgrade solutions, enhancing pump performance and efficiency.

- Extended Lifespan: Regular maintenance and care can significantly extend pump life and reduce the likelihood of failures.

Maintenance Practices

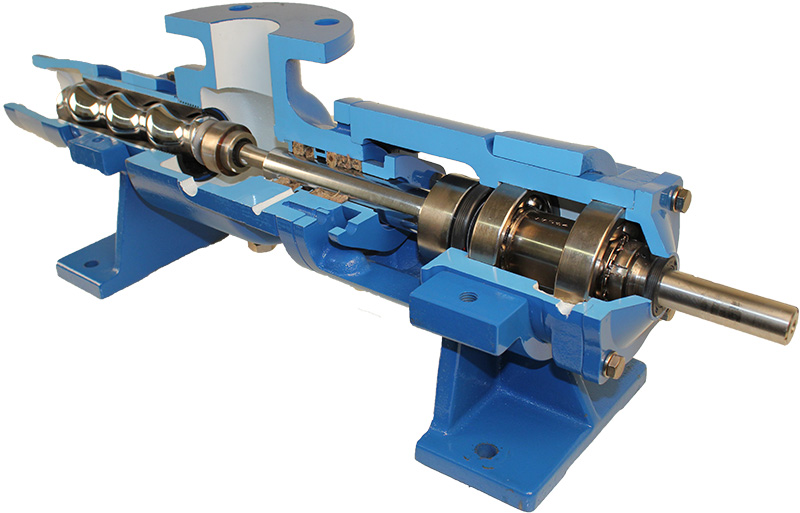

To ensure the efficient operation of progressive cavity pumps, regular maintenance is essential. Here are some fundamental maintenance tips:

- Regularly Inspect Seals: Seals are critical components; regular checks can prevent leakage issues.

- Clean the Pump Body: Keeping the pump body clean prevents debris from causing damage.

- Check Lubrication Systems: Ensure the lubrication system is functioning correctly to avoid wear due to insufficient lubrication.

- Monitor Operational Status: Regularly monitoring the pump’s operational status helps identify potential issues early.

Common Issues and Solutions

Users may encounter several common issues while using progressive cavity pumps. Here are some problems and their solutions:

1. Pump Won’t Start

- Cause: Power failure or overload protection activation.

- Solution: Check the power connections and ensure the voltage is normal; if it’s an overload, investigate the load conditions.

2. Unstable Flow Rate

- Cause: Blocked inlet or internal wear.

- Solution: Inspect the inlet pipeline for blockages and clear any debris; regularly replace worn components.

3. Pump Body Leaking

- Cause: Aging or damaged seals.

- Solution: Regularly check and replace seals to ensure they are in good condition.

4. Excessive Noise

Solution: Verify that the pump is installed correctly, and if necessary, adjust or replace worn components.

Cause: Internal component wear or improper installation.

Send Your Enquiry :