Introduction

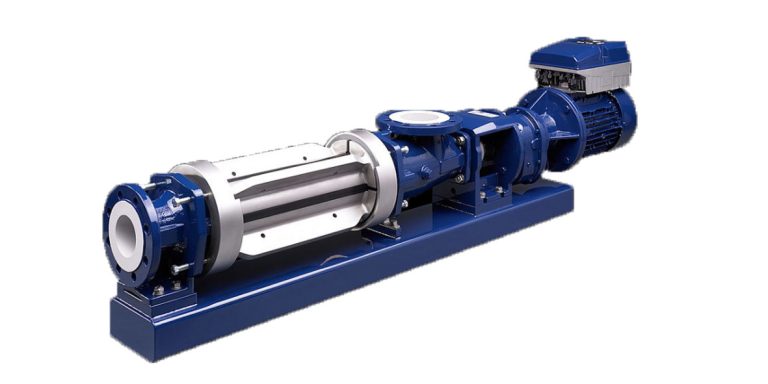

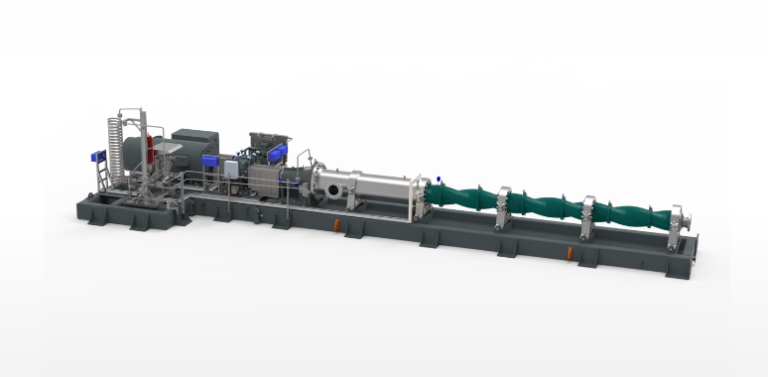

The Allweiler progressive cavity pump is renowned for its exceptional performance and reliability, making it a staple in various industrial applications. This pump design allows it to handle a wide range of fluids, including viscous liquids and those containing solid particles. This article will provide an overview of the Allweiler progressive cavity pump, including its basic principles, operational considerations, and maintenance tips.

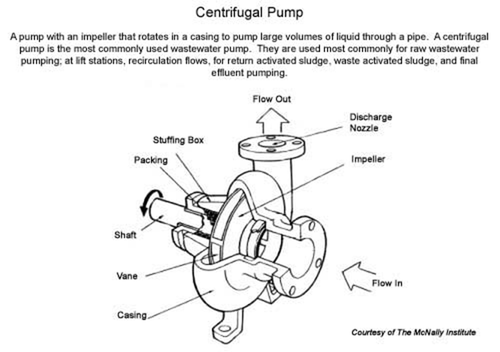

Basic Principles of the Progressive Cavity Pump

The Allweiler progressive cavity pump operates based on the dynamics of helical rotation. Its internal structure consists of one or more pairs of rotors that rotate within a stator, creating a continuous fluid channel. As the rotors turn, fluid is drawn in and expelled, allowing for a smooth flow. This design minimizes the pulsation commonly associated with traditional pumps when handling viscous or complex fluids.

Product Features

The Allweiler progressive cavity pump boasts several notable features:

- High Efficiency: Capable of transporting high-viscosity liquids with lower energy consumption.

- Versatility: Suitable for various fluid types, including corrosive and volatile substances.

- Low Pulsation: Provides a steady flow output, ideal for applications with strict flow requirements.

- Easy Maintenance: Designed for straightforward maintenance and part replacement.

Operational Considerations

When using the Allweiler progressive cavity pump, consider the following operational guidelines:

- Installation Check: Ensure the pump is securely installed and follow the manufacturer’s installation instructions.

- Fluid Characteristics: Familiarize yourself with the properties of the fluid to be transported, including viscosity, temperature, and corrosiveness.

- Pre-Startup Inspection: Before starting the pump, check all connecting pipes for integrity and ensure there are no leaks.

- Monitoring During Operation: Regularly monitor the pump’s operational status, paying attention to pressure, flow rate, and temperature variations.

- Avoid Dry Running: Ensure the pump is filled with liquid before starting to prevent damage from dry running.

Maintenance Tips

Regular maintenance can extend the lifespan of the Allweiler progressive cavity pump. Here are some maintenance suggestions:

- Seal Inspections: Regularly check the condition of the seals and replace them as necessary.

- Pump Cleaning: Periodically clean the pump body inside and out to maintain a conducive working environment.

- Lubrication: Follow the manufacturer’s recommendations for regularly lubricating bearings and other moving parts.

- Motor Checks: Frequently inspect the motor’s operational status to ensure it is functioning correctly.

- Maintenance Records: Maintain a log of maintenance activities, documenting what was done and when for better management.

Common Issues and Solutions

Users may encounter several common issues while operating the Allweiler progressive cavity pump. Here are some potential problems and their solutions:

- Insufficient Flow: This may be caused by blockages in the pump or piping. Check for debris and ensure that the piping is clear.

- Excessive Noise: This could indicate worn bearings or inadequate lubrication. Inspect the bearings and add lubrication as needed.

- Leaks: These may result from damaged seals or improper installation. Check the seals and reinstall or replace as necessary.

- Overheating: This can occur due to high fluid viscosity or cooling system failure. Check the fluid characteristics and ensure the cooling system is functioning properly.

Conclusion

The Allweiler progressive cavity pump is widely used across various industrial sectors due to its unique design and outstanding performance. By following proper operational procedures and conducting regular maintenance, users can ensure efficient operation and longevity of the pump. We hope the information provided in this article helps users better understand and utilize the Allweiler progressive cavity pump.

People also ask

Send Your Enquiry :