[wpseo_breadcrumb]

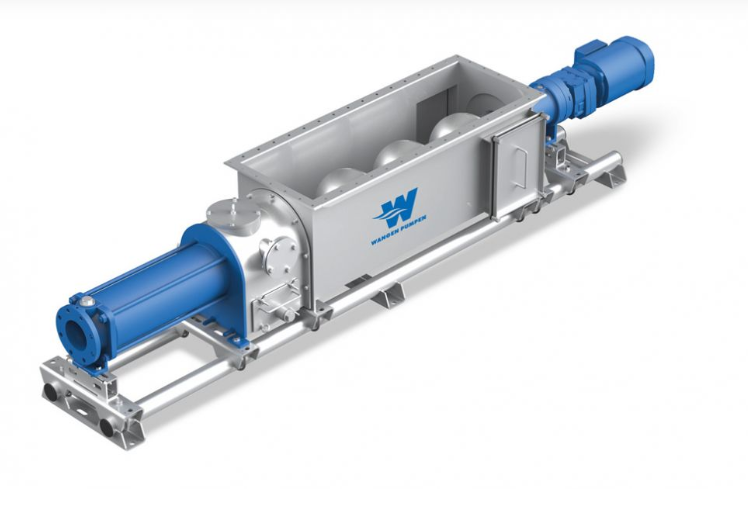

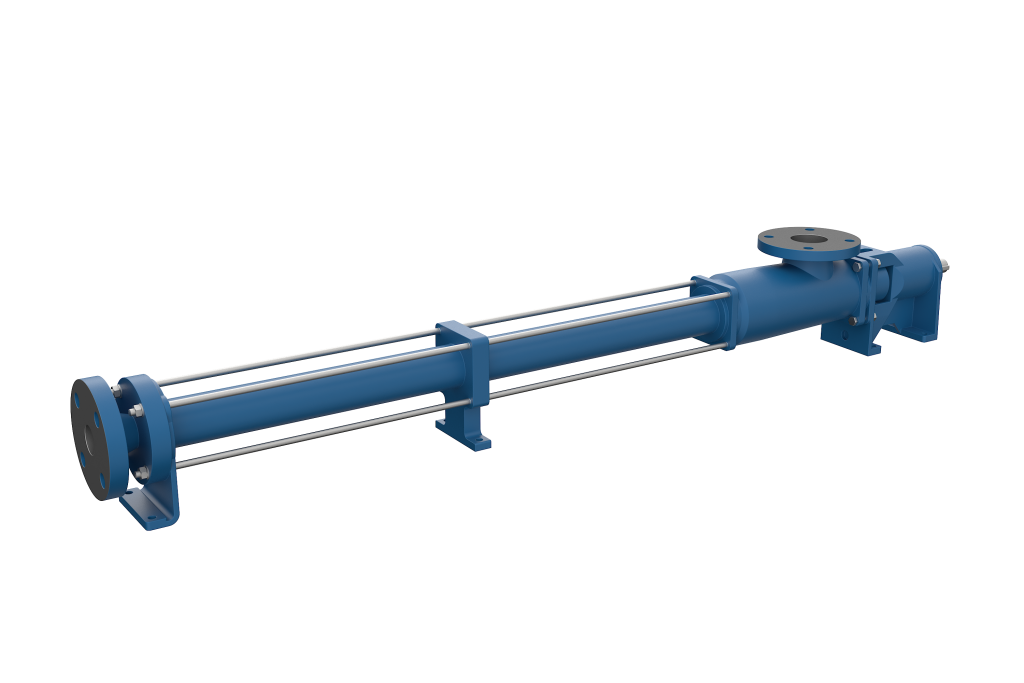

The progressive cavity pump is a widely used type of pump in industrial and engineering applications, known for its unique design and superior performance. Allweiler is a reputable brand in this field, offering high-quality progressive cavity pumps suitable for various operating conditions.

Working Principle of Progressive Cavity Pumps

The working principle of a progressive cavity pump is primarily based on a helical rotor rotating within a fixed stator. The rotation of the rotor compresses the fluid gradually within the cavity and discharges it. The working process can be summarized in the following steps:

- Suction Stage: As the rotor rotates, fluid is drawn into the cavity from the inlet.

- Compression Stage: With further rotation of the rotor, the fluid is progressively compressed, and pressure increases.

- Discharge Stage: The fluid is finally expelled from the outlet, completing the cycle.

Features of Allweiler Progressive Cavity Pumps

Allweiler’s progressive cavity pumps boast several advantageous features that make them stand out in the market.

- High Efficiency: The pump design ensures high performance across various fluid transport scenarios.

- Versatile Adaptability: Capable of handling fluids of different viscosities, including both high and low viscosity fluids.

- Low Pulsation: Smooth fluid flow reduces the impact of pulsation on the system.

- Easy Maintenance: Simple structure allows for easy maintenance and part replacement, minimizing downtime.

Application Areas

Allweiler progressive cavity pumps have a wide range of applications across multiple industries. Here are some key application areas:

- Chemical Industry: Used for transporting various chemicals, including corrosive and high-viscosity liquids.

- Food Industry: Suitable for conveying food and beverages, meeting relevant hygiene standards.

- Oil and Gas: Employed in oil refining and natural gas transport, capable of handling high-viscosity oils.

- Wastewater Treatment: Assists in the transportation of various wastewater and sludge in treatment processes.

Advantages and Disadvantages of Progressive Cavity Pumps

When selecting a progressive cavity pump, it is essential to consider both its advantages and disadvantages to make the best decision.

Advantages

- Stable Flow: The design allows for a stable flow rate, making it suitable for applications with strict flow requirements.

- High Wear Resistance: The materials used in the pump typically exhibit good wear resistance, extending service life.

- Multifunctionality: Capable of not only transporting liquids but also handling fluids with solid particles.

Disadvantages

- Higher Initial Investment: Compared to traditional pumps, the purchase cost may be higher.

- Sensitivity to Fluid Characteristics: Performance can be sensitive to changes in fluid temperature and viscosity.

- Maintenance Requirements: While maintenance is relatively simple, regular checks and upkeep are necessary to ensure proper operation.

Reasons to Choose Allweiler Progressive Cavity Pumps

There are numerous reasons to choose Allweiler progressive cavity pumps, with the following points being particularly significant:

- Brand Reputation: Allweiler has a strong market reputation and extensive industry experience.

- Technical Support: Provides comprehensive technical support and services to ensure smooth product usage.

- Innovative Design: Continuously innovates to introduce more efficient and environmentally friendly pump products.

Conclusion

Allweiler progressive cavity pumps, with their efficient performance, broad applications, and reliable brand image, have become the preferred equipment in many industries. Understanding their working principle, features, and applicable areas is crucial when selecting a pump. Whether in the chemical, food, or wastewater treatment industry, Allweiler progressive cavity pumps can meet diverse customer needs and provide robust support for industrial production.

Send Your Enquiry :