[wpseo_breadcrumb]

Introduction

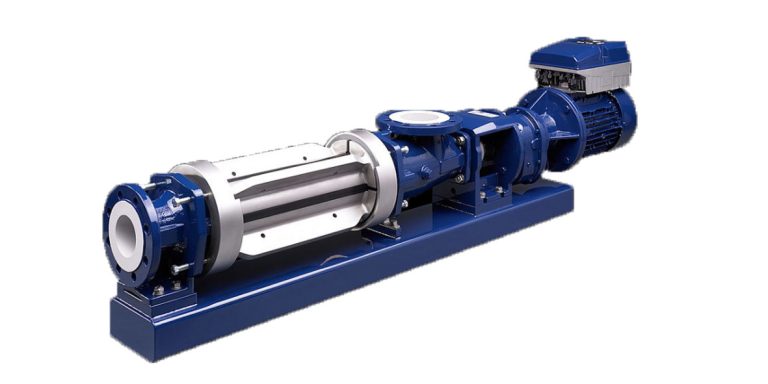

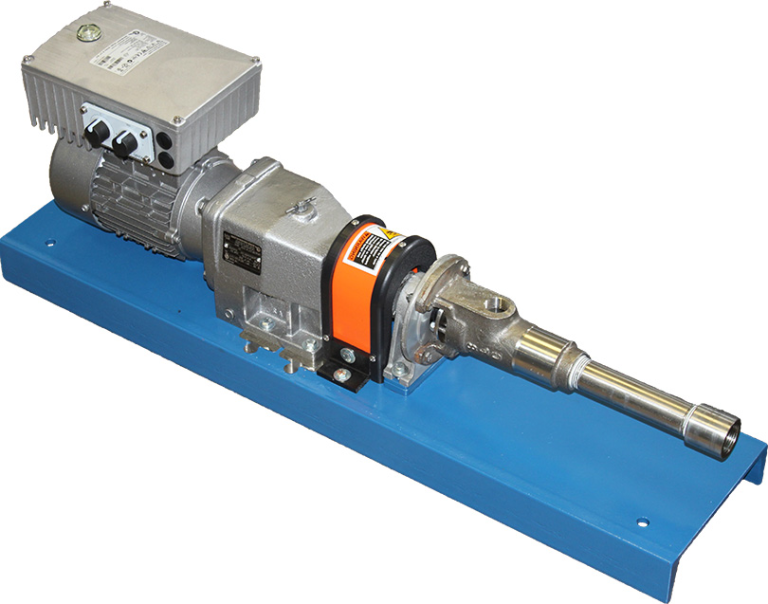

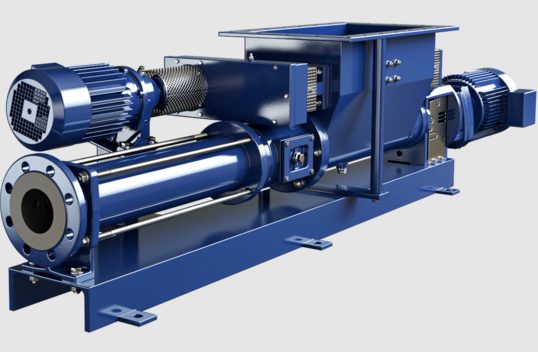

Micro progressive cavity pumps are specialized devices designed to move fluids in a controlled and efficient manner. These pumps are particularly useful in applications requiring precise flow rates and gentle handling of sensitive materials. Their unique design allows them to perform effectively across various industries.

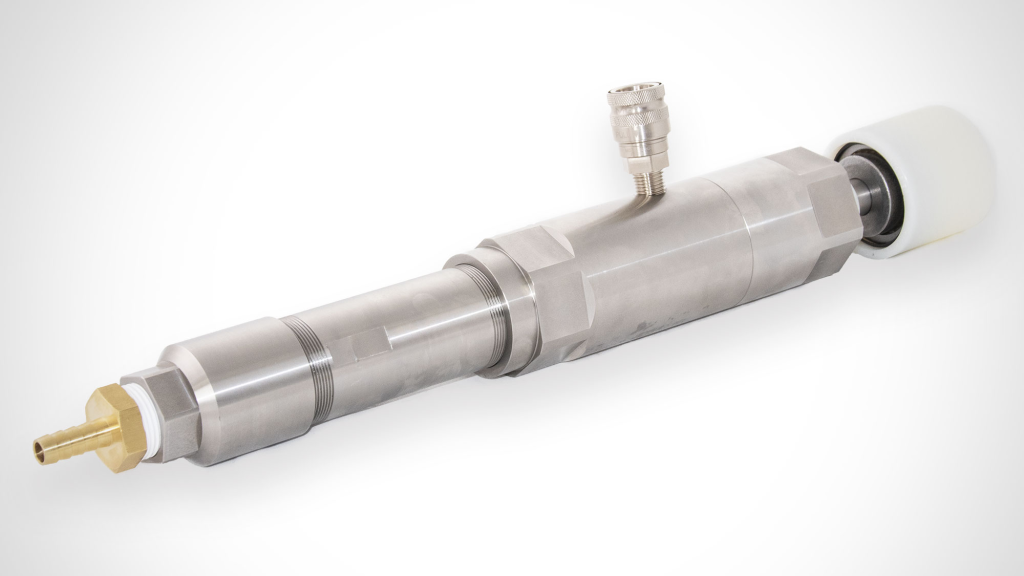

How It Works

The micro progressive cavity pump operates through a helical rotor and a stator. The rotor is typically made of a durable material, while the stator is crafted from elastomeric materials. This combination creates a series of cavities that transport the fluid as the rotor turns.

Key Components

- Rotor: The rotating element that moves the fluid.

- Stator: The stationary element that forms the cavities with the rotor.

- Drive Shaft: Connects the rotor to the motor, enabling rotation.

- Seals: Prevent leakage and protect the pump from contaminants.

Advantages

Micro progressive cavity pumps offer several benefits that make them ideal for specific applications:

- Precision: They provide accurate flow rates, making them suitable for metering applications.

- Versatility: These pumps can handle a wide range of viscosities, from thin liquids to highly viscous materials.

- Gentle Handling: The design minimizes shear stress on the fluid, preserving the integrity of sensitive materials.

- Self-Priming: They can draw fluid into the pump without needing additional priming, enhancing efficiency.

- Low Pulsation: The flow generated is smooth and continuous, reducing wear and tear on system components.

Applications

Micro progressive cavity pumps find use in various industries, including:

- Food and Beverage: For transferring ingredients and processing delicate products.

- Pharmaceutical: In precise dosing and handling of viscous formulations.

- Chemical: For moving corrosive or abrasive fluids safely.

- Cosmetics: In the formulation of lotions and creams where consistency is key.

- Wastewater Treatment: For pumping sludge and other challenging materials.

Considerations

When selecting a micro progressive cavity pump, several factors should be taken into account:

- Fluid Characteristics: Understanding the viscosity, temperature, and chemical composition of the fluid is essential.

- Flow Rate Requirements: Determining the necessary flow rate will guide the selection process.

- Material Compatibility: Ensuring that the pump materials can withstand the fluid being pumped is crucial for longevity.

- Maintenance Needs: Some designs may require more frequent maintenance than others, affecting operational efficiency.

Conclusion

Micro progressive cavity pumps are invaluable tools in many industries due to their precision, versatility, and ability to handle a variety of fluids. As technology advances, these pumps continue to evolve, offering even greater efficiency and reliability. By understanding their features and applications, businesses can make informed decisions to enhance their fluid handling processes.

Send Your Enquiry :