[wpseo_breadcrumb]

Introduction

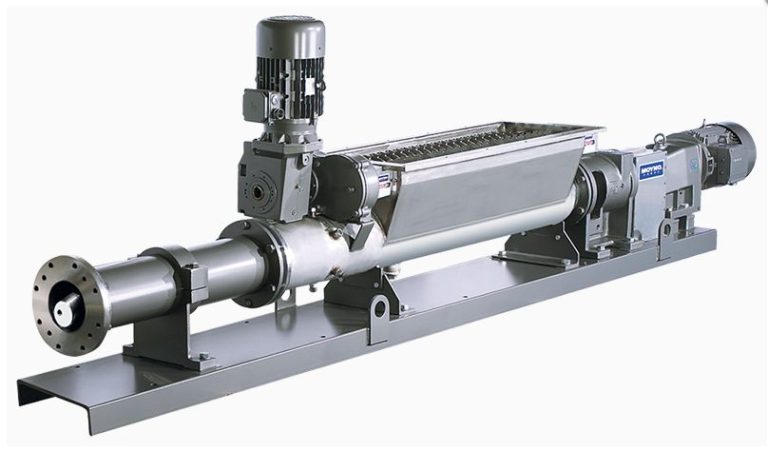

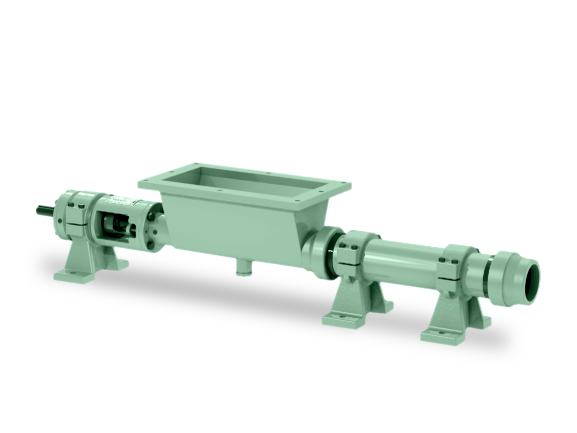

The Continental Progressing Cavity Pump is a vital piece of equipment used across various industries for its unique ability to handle a wide range of fluids. This type of pump is particularly known for its efficiency in transporting viscous liquids, making it an essential tool in sectors such as oil and gas, wastewater treatment, and food processing.

Working Principle

The functioning of a progressing cavity pump is based on a simple yet effective mechanism. It consists of a helical rotor that rotates within a stator, creating a series of cavities that move the fluid from the inlet to the outlet. This design allows for a continuous flow of liquid, providing a smooth and consistent discharge.

Key Components

- Rotor: A helical-shaped metal component that rotates and moves the fluid.

- Stator: A rubber or elastomeric lining that forms the cavities with the rotor, ensuring a tight seal.

- Drive System: Typically an electric motor that powers the rotor’s rotation.

- Inlet and Outlet: The points where the fluid enters and exits the pump.

Advantages

The Continental Progressing Cavity Pump offers several advantages that make it a preferred choice in various applications:

- Versatility: Capable of handling a wide range of fluids, including those with high viscosity and solid content.

- Gentle Handling: The pump operates with low shear, making it ideal for sensitive fluids that cannot tolerate high pressures.

- Consistent Flow: Provides a steady and uniform flow rate, regardless of the fluid’s viscosity.

- Self-Priming: Designed to be self-priming, which minimizes the need for additional equipment.

- Low Maintenance: Generally requires less frequent maintenance due to its durable construction and fewer moving parts.

Applications

The versatility of the Continental Progressing Cavity Pump allows it to be used in various fields:

- Oil and Gas: Effective in transporting crude oil and other viscous fluids.

- Wastewater Treatment: Used for pumping sludge and other thick liquids in treatment facilities.

- Food Processing: Ideal for transferring thick pastes, sauces, and other food products without damaging them.

- Chemical Industry: Handles corrosive and viscous chemicals with ease.

Conclusion

The Continental Progressing Cavity Pump stands out as a reliable and efficient solution for a multitude of pumping needs. Its unique design and operational benefits make it an indispensable tool in many industries. Whether for handling viscous liquids, ensuring consistent flow, or minimizing maintenance, this pump remains a preferred choice for professionals seeking quality and performance. Understanding its components and advantages allows users to maximize its potential, making it a valuable asset in any pumping application.

Send Your Enquiry :