[wpseo_breadcrumb]

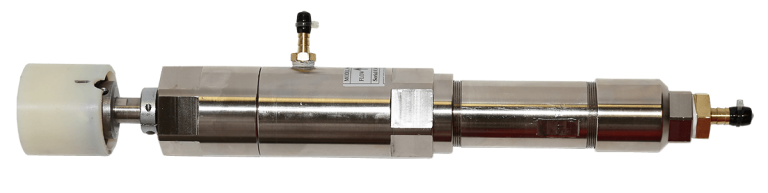

Progressive cavity pumps are a vital component in various industries, known for their efficiency and reliability. Continental Pumps has established itself as a leader in this technology, providing solutions that meet the diverse needs of its customers.

What are Progressive Cavity Pumps?

Progressive cavity pumps operate using a unique design that allows for the smooth and continuous transfer of fluids. They consist of a helical rotor that turns within a stator, creating cavities that move the fluid from the inlet to the outlet. This design minimizes turbulence and shear, making these pumps ideal for handling viscous and shear-sensitive materials.

Key Advantages of Continental Pumps Progressive Cavity

- Versatility

Progressive cavity pumps can handle a wide range of fluids, from thick sludges to delicate emulsions. This versatility makes them suitable for various applications, including wastewater treatment, food processing, and chemical manufacturing. - Consistent Flow

One of the standout features of these pumps is their ability to provide a steady flow rate, regardless of the pressure changes in the system. This consistency is crucial in processes that require precise fluid delivery. - Low Maintenance

The design of progressive cavity pumps reduces wear and tear, leading to lower maintenance needs. With fewer parts exposed to the fluid, the risk of damage is minimized, resulting in longer operational life. - Self-Priming Capability

Continental Pumps’ progressive cavity models are designed to be self-priming, allowing them to efficiently handle air and gas entrainment. This feature is particularly beneficial in applications where the fluid may not always be available. - Energy Efficiency

These pumps are engineered to operate efficiently, which translates to lower energy consumption. Their ability to maintain flow under varying conditions means less energy is wasted in the pumping process.

Applications of Progressive Cavity Pumps

Progressive cavity pumps are utilized in several industries due to their adaptability. Here are some common applications:

- Wastewater Treatment: Effective in transporting sludge and other viscous materials.

- Food and Beverage: Ideal for handling delicate products without damaging them.

- Chemical Processing: Suitable for moving corrosive and abrasive fluids.

- Oil and Gas: Used in applications that require the transport of viscous hydrocarbons.

- Pharmaceuticals: Ensures precise dosing and consistent flow for sensitive formulations.

Conclusion

Continental Pumps’ progressive cavity technology provides an effective solution for a wide variety of fluid transfer needs. With their numerous advantages, including versatility, consistent flow, and low maintenance, these pumps are an excellent choice for industries that demand reliability and efficiency. As technology continues to evolve, progressive cavity pumps will undoubtedly remain a cornerstone in fluid handling solutions.

Send Your Enquiry :