[wpseo_breadcrumb]

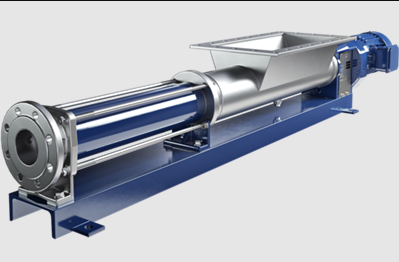

Progressive cavity pumps are widely used in various industries due to their unique design and efficiency. The compact version of these pumps offers numerous advantages, making them a popular choice for applications where space is at a premium. This article explores the features, benefits, and applications of compact progressive cavity pumps.

Features of Compact Progressive Cavity Pumps

- Design and Structure

Compact progressive cavity pumps are designed with a rotating helical rotor and a stationary stator. This design allows for a smooth, continuous flow of fluids, making them ideal for handling viscous materials. - Versatility

These pumps can handle a wide range of fluids, including slurries, pastes, and shear-sensitive liquids. Their adaptability makes them suitable for various industrial applications. - Compact Size

The compact nature of these pumps allows them to fit into tight spaces, making them a perfect choice for installations where traditional pumps would be too large.

Benefits of Using Compact Progressive Cavity Pumps

- High Efficiency

Due to their positive displacement mechanism, these pumps provide a consistent flow rate, reducing energy consumption and operating costs. - Gentle Handling of Fluids

The design minimizes turbulence, ensuring that sensitive materials remain intact. This is particularly important in industries like food and pharmaceuticals. - Low Maintenance

With fewer moving parts than other pump types, compact progressive cavity pumps require less maintenance, leading to reduced downtime and lower operational costs. - Self-Priming Capability

These pumps can handle fluids with varying viscosities and can self-prime, which simplifies installation and operation.

Applications of Compact Progressive Cavity Pumps

- Food and Beverage Industry

Used for transporting sauces, creams, and other viscous food products without damaging their integrity. - Chemical Processing

Ideal for handling corrosive and viscous chemicals, ensuring safe and efficient transfer. - Wastewater Treatment

Effective in moving sludge and other thick materials in treatment facilities. - Oil and Gas

Utilized for transferring crude oil and other viscous fluids in extraction and transportation processes.

Conclusion

Compact progressive cavity pumps are an excellent solution for industries requiring efficient fluid transfer in limited spaces. Their unique design and operational benefits make them a preferred choice for various applications. As industries continue to evolve, the demand for reliable and compact pumping solutions will likely increase, solidifying the role of these pumps in modern manufacturing and processing environments.

People also ask

Send Your Enquiry :