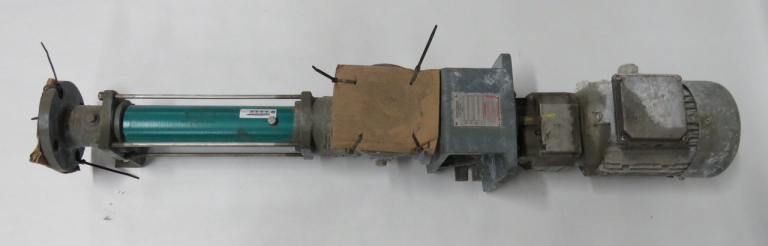

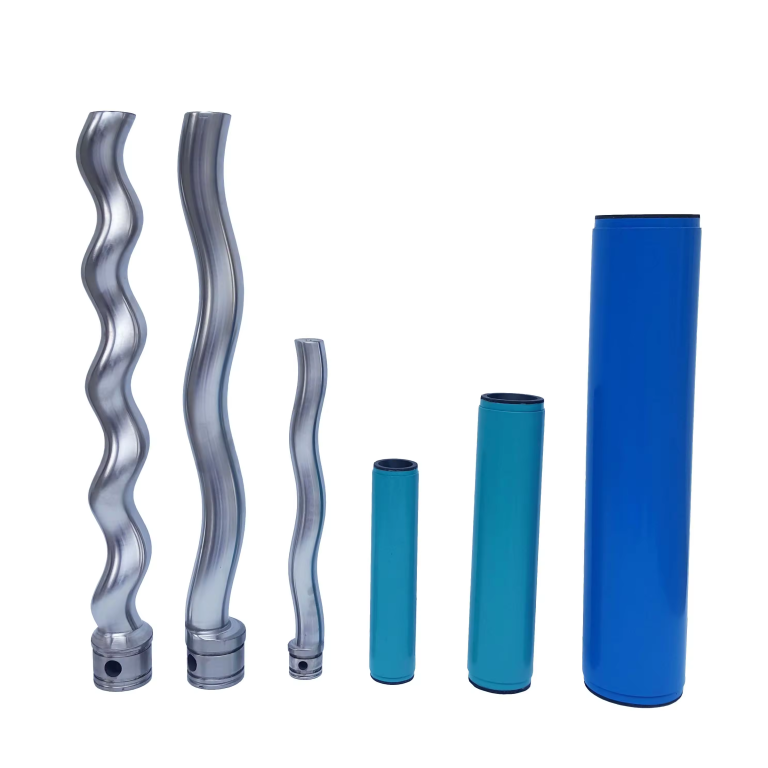

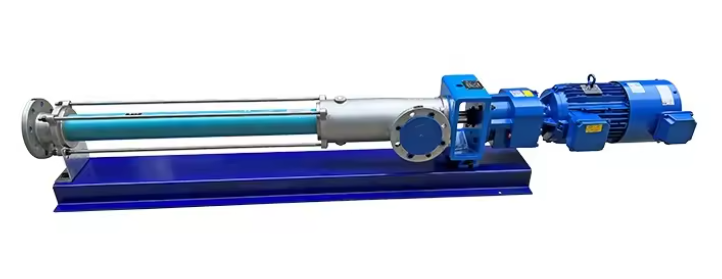

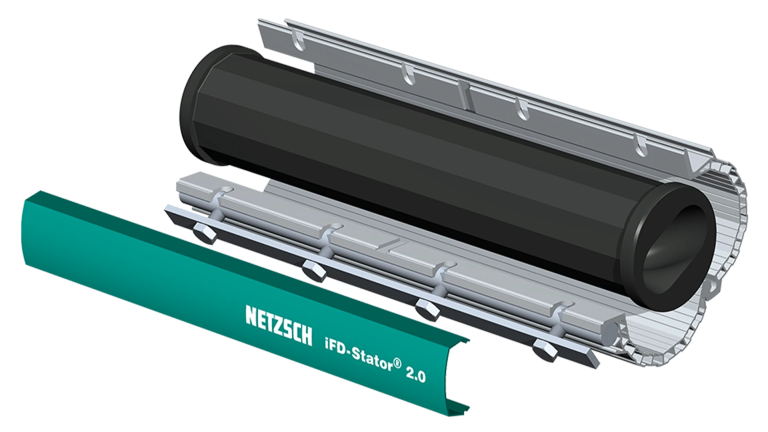

NM031BY02S12B Rotor

A Key Component in Progressive Cavity Pumps The NM031BY02S12B Rotor is a critical component in progressive cavity pumps, playing a crucial role in their efficient operation. This specialized rotor is designed to work in tandem with the stator to create a progressive cavity that enables the pump to handle a wide range of fluids with…