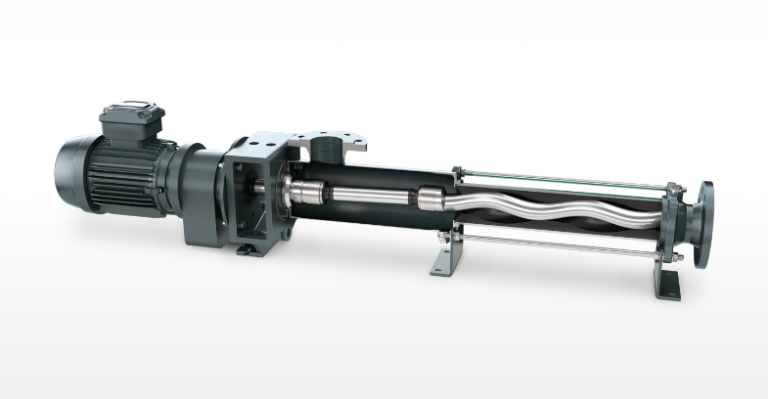

Rotor design:

The manufacturing process of the rotor is very precise, and the gap between the rotor and the stator is controlled within a range of only tens of microns. This extreme dimensional accuracy not only effectively reduces leakage and backflow losses, but also ensures the high efficiency of the pump.

The rotor is made of high-quality alloy steel, and after surface precision machining and coating treatment, the wear resistance is greatly improved. This high-strength, high-wear-resistant rotor can operate stably for a long time under harsh working conditions.

Unlike traditional fixed-curvature rotors, NETZSCH adopts a variable curvature rotor design. This flexible rotor shape can be adjusted according to the characteristics of different fluids, greatly improving the adaptability of the pump.

The rotor adopts a pressure difference driven operation mode. The pressure change inside the stator directly acts on the rotor to generate a driving force, driving it to rotate synchronously. This unique driving mechanism ensures the high delivery efficiency of the pump.

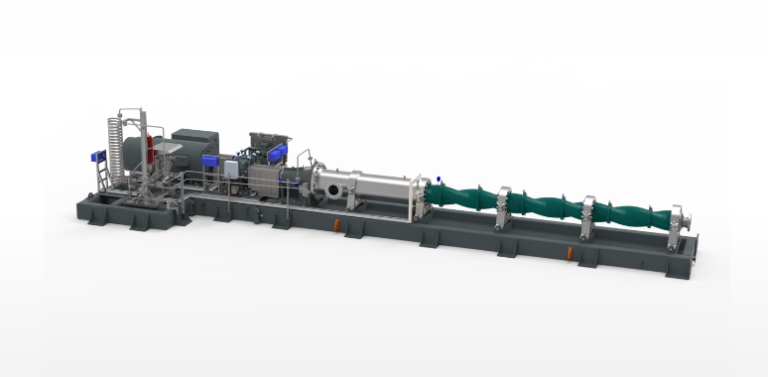

As an efficient and reliable industrial conveying equipment, screw pumps have been widely used in many fields such as chemical, pharmaceutical, and food.

Among them, the NETZSCH NM063BY02S12B screw pump has become a popular product in the industry with its excellent performance.

The unique stator and rotor design is the core advantage of the NETZSCH NM063BY02S12B. The close fit between the rotor and the stator effectively reduces leakage and backflow losses.

People also ask

Send Your Enquiry :