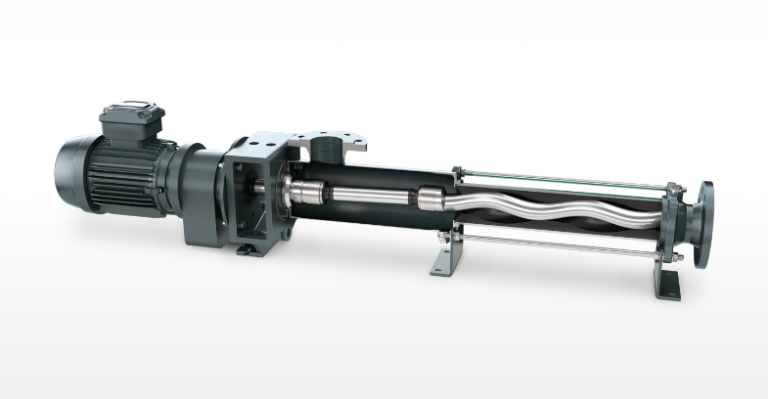

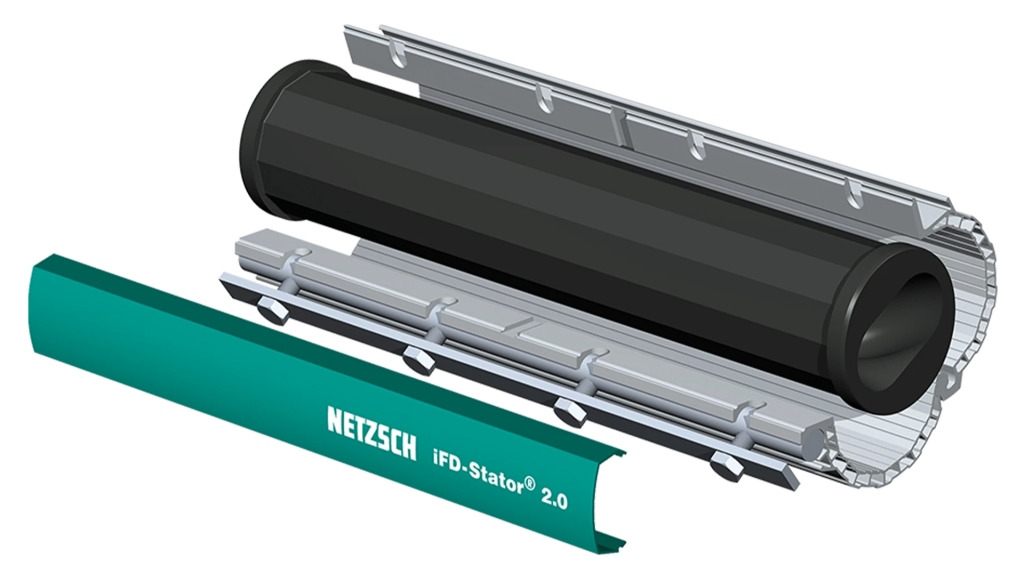

The stator is the outer shell of the rotor, usually made of a cast iron shell and a rubber inner body. The spiral groove inside the stator and the screw of the rotor are integrated to form a closed spiral chamber in which the liquid is transported. This spiral chamber is a key part of the screw pump because it controls the flow and pressure of the liquid. The inner surface of the stator must be smooth to ensure that the liquid passes smoothly through the pump.

The stator operates by interacting with the rotor.

Specifically, the role of the stator is to transport the liquid entering the suction chamber to the extrusion chamber, and in the extrusion chamber, the pressure oil is discharged from the pump due to the compression of the liquid.

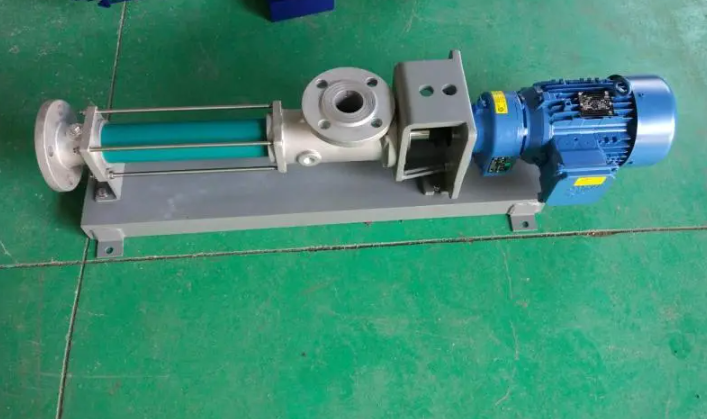

The NM015BY02S12B screw pump has a simple and compact structure, reliable operation, and easy maintenance. It has a large flow and power range and strong self-priming ability. However, with the increase in usage time and the increase in wear, the inner diameter of the stator gradually decreases or even becomes blocked.

So how should we prevent or solve it?

- Clean the stator regularly

In daily use, worn parts and wearing parts should be checked and replaced in time. If the surface of the sleeve is scratched, stop using it immediately and replace it with a new sleeve in time; when the sealing ring is cracked, replace it with a new sealing ring immediately. - Avoid impurities from entering

During daily operation, pay special attention to some operating links that are easy to cause foreign matter to mix into the equipment. For example, when filling lubricating oil, be sure to keep the refueling port away from the rotating part to avoid the mixing of impurities. - Correctly select lubricants

As one of the important media of mechanical products, lubricating oil is a very important aspect for mechanical equipment, so we must also be cautious when choosing lubricating oil. If the wrong choice is made, it may affect the performance of the equipment - Regular inspection and maintenance

Some losses will inevitably occur during work, and we should take corresponding measures according to the actual situation. For example: when the thickness of the oil stain in the casing is found to be about 0.2mm, it should be cleaned in time to maintain good heat transfer effect, reduce energy consumption, and improve economic benefits.

People also ask

Send Your Enquiry :