BN10-12L stator seepex

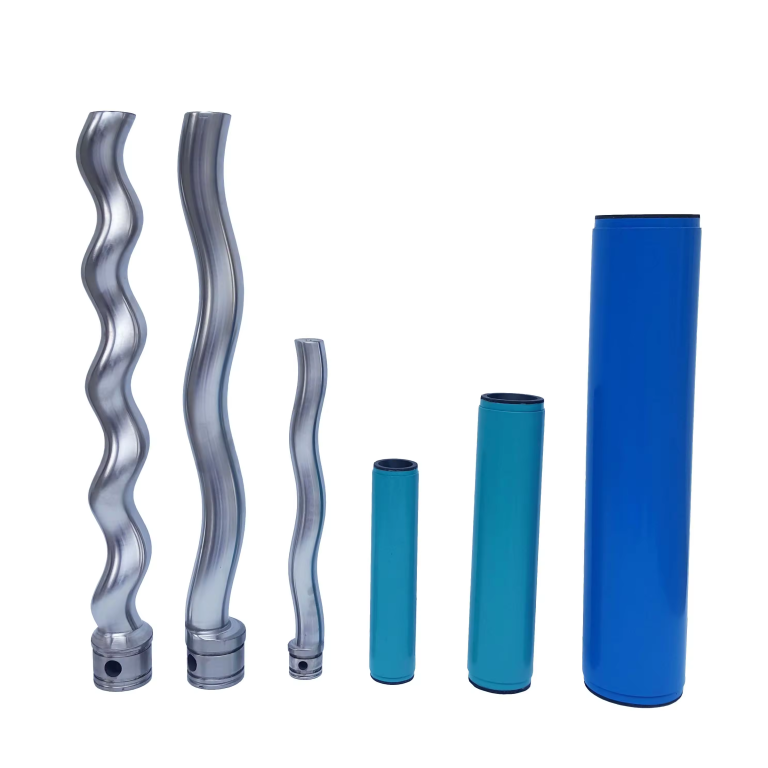

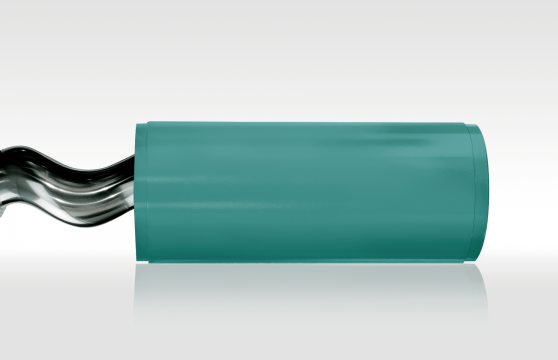

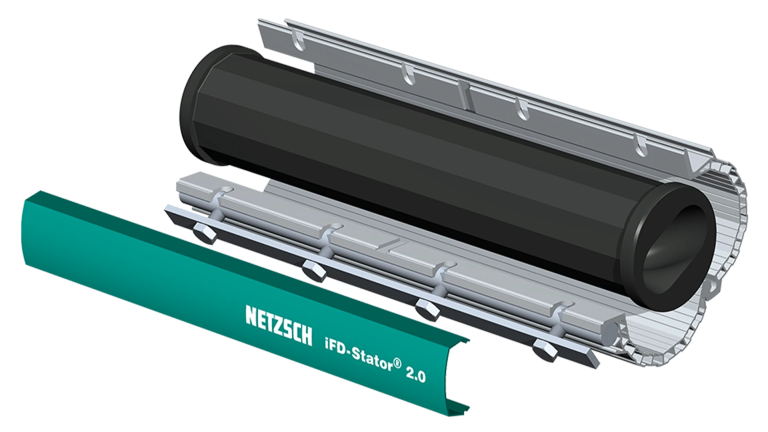

The core component of seepex BN10-12L screw pump – stator The stator is one of the key components of the seepex BN10-12L screw pump. It works with the rotor to complete the fluid delivery. The main features of the seepex BN10-12L stator are as follows: Product advantages Compared with similar products, the seepex BN10-12L stator…