[wpseo_breadcrumb]

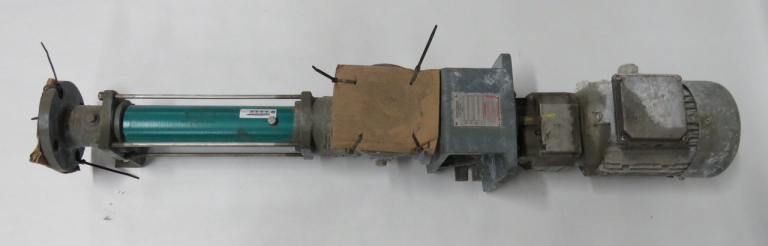

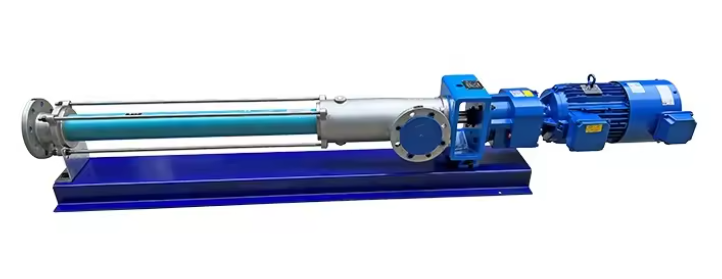

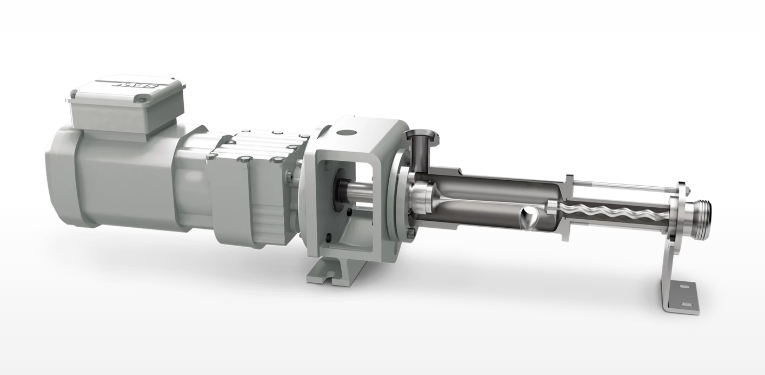

The stator is a very important component in the screw pump. It works with the rotor to complete the function of fluid transportation.

The stator has the following characteristics:

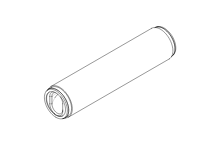

Netzsch NM038BY02S12B model screw pump uses a stator made of natural rubber (NBR). It has excellent wear resistance and corrosion resistance. This elastic material can form a good seal with the rotor and improve the sealing performance of the pump. The inner surface of the stator is designed in a spiral shape, which perfectly matches the spiral tooth shape on the outer surface of the rotor. When the rotor rotates, the volume of the pump chamber will continue to change, thereby driving the flow of fluid.

The outer surface of the stator is a cylindrical structure that can be firmly installed in the inner cavity of the pump body. There is a mounting hole in the center of the stator for fixing it to the pump housing.

There is a small gap between the stator and the rotor. This gap design ensures good sealing performance inside the pump and avoids fluid leakage. The elasticity of the rubber material can also play a certain shock-absorbing role, which improves the smooth operation of the pump.

Since the stator is a component that wears faster inside the pump, it needs to be checked regularly and replaced in time. The replacement frequency depends on the working conditions, such as medium properties, working pressure and speed.

The good design and precision manufacturing of the stator ensure that the Netzch screw pump can operate reliably under various working conditions and transport various industrial media with high viscosity and solid content.

The stator of the Netzsch NM038BY02S12B screw pump is a key component, and its reliability and performance directly affect the service life and working efficiency of the entire pump system. The carefully designed stator structure ensures the sealing inside the pump and the stability of fluid delivery.

people also ask

Send Your Enquiry :