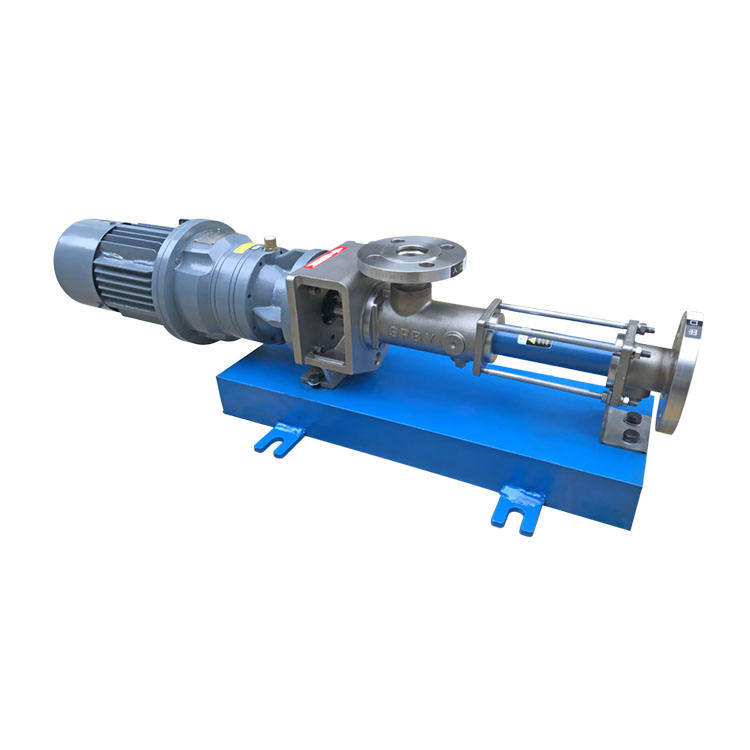

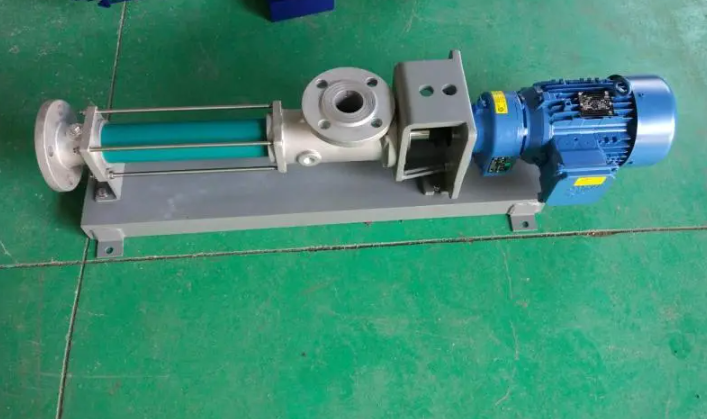

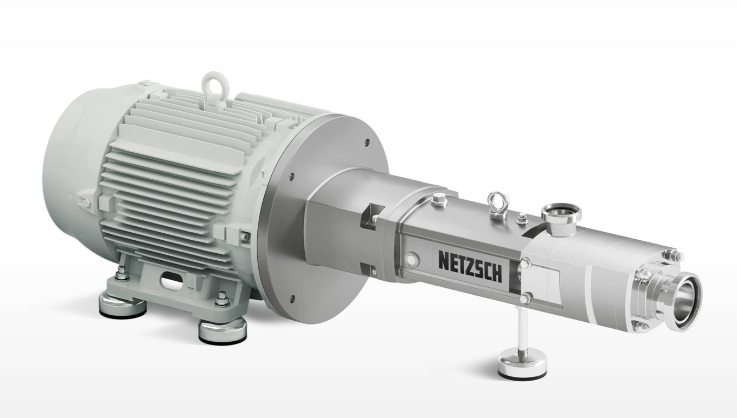

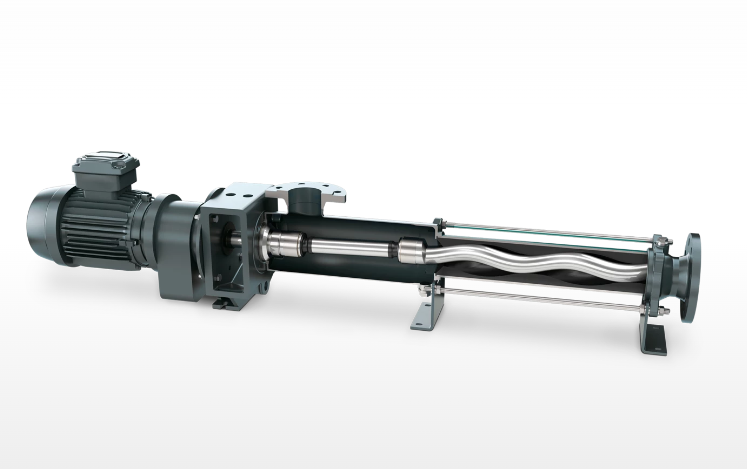

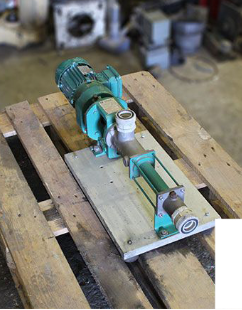

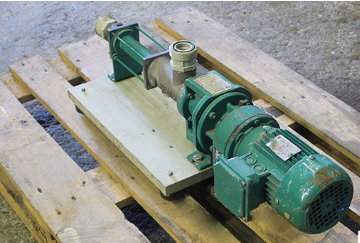

The Netzsch NM015BY02S12B is a very versatile progressive cavity pump that is used in many industrial applications.

Manufacturer: Netzsch Pumps

Model: NM015BY02S12B

Type: Progressing Cavity Pump

External Diameter: 28 mm

Oil Per Joint: 1.5 cm3

Rated Torque: 300 Nm

No. Stages: 2

Rated Force: 550 N

Pump Size: 15

Nominal Diameter: 32 DN

Max. Permissible Pressure Difference Anti–Clockwise: 12 bars

Attachment: NORD 71L/4 TFI 3 PHASE ELECTRIC MOTOR

Manufacturer: NORD

Model: 71L/4 TFI

Type: 3 Phase Electric Motor

Here are some of the main application areas and benefits of the Netzsch NM015BY02S12B:

Application areas

Chemical industry: suitable for the transportation of various chemicals, such as acids, alkalis, solvents, paints, coatings, etc.

Food and beverage industry: can be used to transport foods of various viscosities and containing solid particles, such as syrups, jams, chocolates, etc.

Pharmaceutical industry: can be used to transport various pharmaceutical raw materials and products, such as emulsions, suspensions, etc.

Environmental protection industry: can be used for the transportation and circulation of sludge, sewage, slurry, etc.

Building materials industry: suitable for the transportation of building materials of various viscosities such as mortar, fillers, etc.

Advantages

Good wear resistance: made of high-quality materials, long service life.

Excellent sealing performance: can prevent leakage and pollution.

Simple and reliable operation: no need for excessive maintenance, smooth operation.

Compact size, flexible installation.

High head, high transportation efficiency.

People also ask

Send Your Enquiry :