[wpseo_breadcrumb]

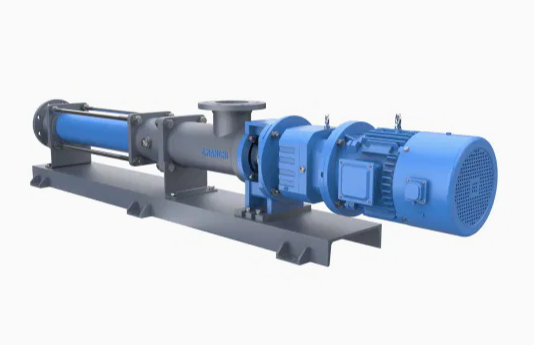

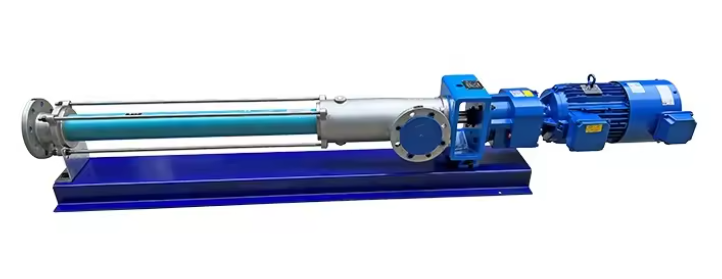

Durable and reliable Netzsch NM021BY02S12B screw pump

In all areas of industrial production, reliable conveying equipment plays a vital role. As a leading pump manufacturer in the industry, Netzsch’s NM021BY02S12B screw pump is such a trustworthy product. As a member of Netzsch’s NM series of screw pumps, NM021BY02S12B has been widely praised for its excellent performance characteristics.

First of all, its reliable and durable mechanical structure makes it suitable for conveying a variety of industrial media, from powders to slurries to viscous materials. Its excellent self-priming ability and dry running characteristics further expand its application range.

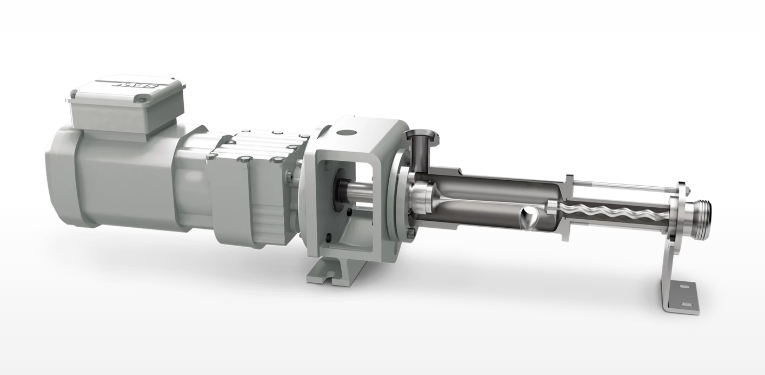

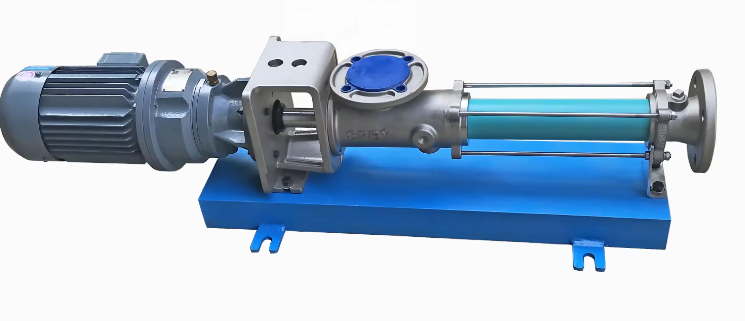

NM021BY02S12B has shown excellent stability during use. Thanks to the unique design of the screw pump, the rotor is made of wear-resistant alloy material and can withstand high pressure and high speed. The stator is made of flexible rubber material, which forms a seal with the rotor to improve impact resistance. This product can provide pulsation-free and stable flow conveying effect, greatly improving the working performance of downstream equipment. Another highlight is its reversible operation function, which brings greater flexibility to the user’s production process.

In terms of structural design, NM021BY02S12B adopts a simple and easy-to-maintain layout, which greatly reduces the user’s later maintenance costs. With the gray cast iron pump body, corrosion resistance is also guaranteed. The powerful driving power can also meet the needs of various working conditions. With excellent performance parameters and applicability, Netzsch NM021BY02S12B screw pumps are widely used in chemical, papermaking, food, pharmaceutical and other fields

The chemical industry is one of the important application areas of Netzsch NM021BY02S12B. In chemical production, it is common to have various viscous and easy-to-agglomerate media that need to be transported. Netzsch screw pumps can easily cope with these challenges with their excellent self-priming ability to ensure the stability of chemical production.

The papermaking industry is also another major application area of Netzsch NM021BY02S12B. In papermaking production, slurry transportation is a key link, and the performance requirements of the conveying equipment are very high. Netzsch NM021BY02S12B ensures smooth pulp transportation and improves paper production efficiency with its pulsation-free and stable flow characteristics.

In addition, Netzsch NM021BY02S12B is also widely used in the food and pharmaceutical industries. In these industries, the conveying medium usually has high requirements for hygiene and safety. Netzsch NM021BY02S12B uses corrosion-resistant materials and a simple and easy-to-clean design to meet the special needs of the food and pharmaceutical industries.

people also ask

Send Your Enquiry :