[wpseo_breadcrumb]

Compliant and Efficient of NEMO Sanitary Pumps

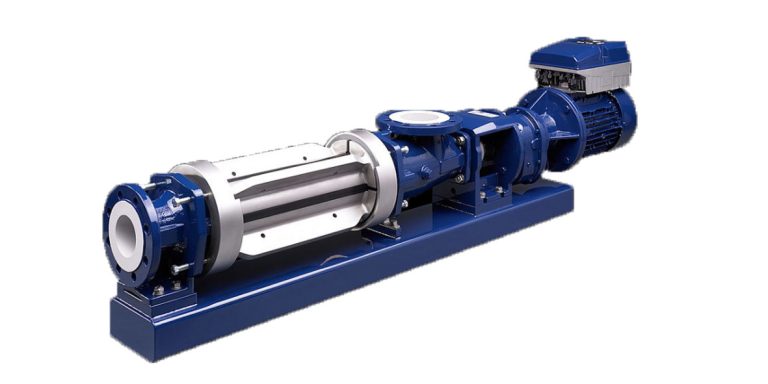

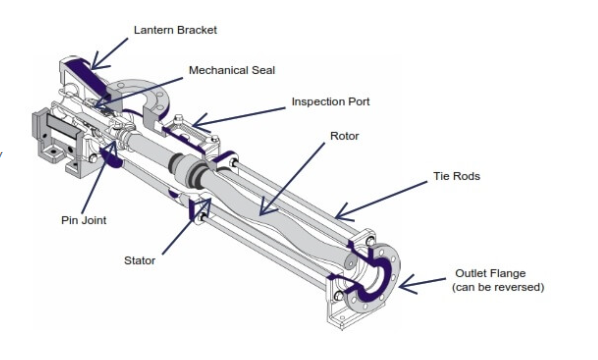

The NEMO sanitary pumps meet strict regulatory standards, including use of Food and Drug Administration (FDA) compliant materials and design in accordance with food application specifications to prevent the product from lodging in areas where bacteria may form. NEMO sanitary pumps are designed, produced, and inspected in accordance with European Hygienic Equipment Design Group (EHEDG) regulations and also meet 3-A Sanitary Standards specifications. Metallic parts of NEMO food grade sanitary pumps are stainless steel 316 with polished internal surfaces (32 Ra). Several superior FDA-compliant elastomers have been developed with excellent mechanical and rheological properties. These wear-resistant elastomers are extremely efficient at handling solid pieces of meat with variable lubricity.

The Dexcription of NETZSCH Announces NEMO® Progressing Cavity Pump

This NETZSCH pump features a unique design and engineering principles, enabling it to excel in various industrial sectors. With its progressive cavity design, the NEMO® pump offers precise and reliable fluid transfer, making it ideal for applications requiring gentle handling of shear-sensitive, viscous, or abrasive media. Its robust construction and efficient performance ensure optimal productivity and reduced downtime. The NEMO® Progressing Cavity Pump is set to redefine industry standards, providing a versatile and reliable solution for fluid handling needs.

The Application of NEMO® Progressing Cavity Pump

The NEMO® Progressing Cavity Pump from NETZSCH is a game-changer for fluid handling applications. Its unique design and engineering principles make it ideal for industries that require precise and reliable fluid transfer. Whether it’s shear-sensitive, viscous, or abrasive media, this pump excels in handling them all. With its robust construction and efficient performance, the NEMO® pump ensures optimal productivity and minimal downtime. It’s set to redefine industry standards and provide a versatile and dependable solution for fluid handling needs.

The Features of NEMO® Progressing Cavity Pump

- Unlike rotary lobe pumps, sanitary progressing cavity pumps can handle greater pressures, a wide range of viscosities, and the variability of product that meat processing facilities require. In addition, sanitary progressing cavity pump performance is not affected by the variations and changes that occur during production and cleaning processes. Sanitary progressing cavity pumps also offer a positive sealing effect between the rotor and stator, creating distinct cavities, which permits the handling of higher pressure per stage than rotary lobe pumps.

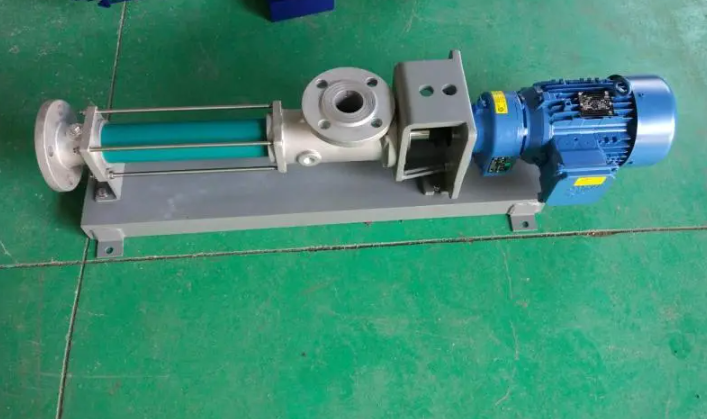

- NEMO sanitary pumps are easy to maintain, and have additional features to enable ease of assembly and disassembly to facilitate clean-in-place and full service-in-place requirements dictated by meat product standards. The sanitary pumps use a stainless steel washdown motor for ease of cleaning, and can be mounted on stainless steel baseplates with wheels and a handlebar for ease of movement. The open hopper and feed screw of the NEMO sanitary pumps provide a smooth entry for product in the suction housing of the pump and into the conveying elements.

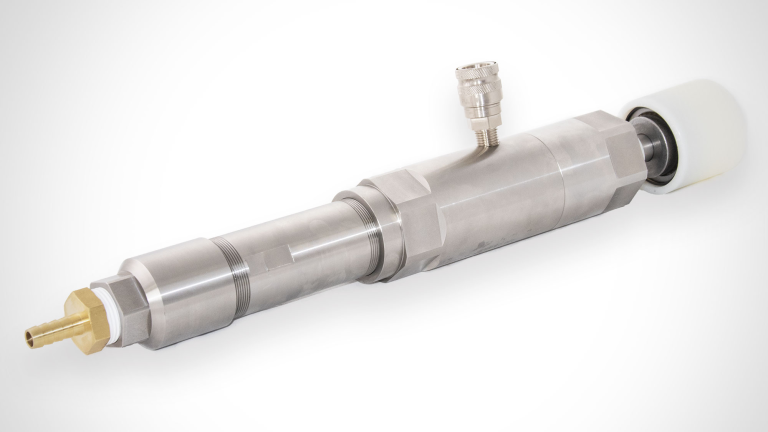

- NEMO sanitary pumps are carefully designed to ensure precise interference between the rotor and stator, thereby delivering the maximum possible pressure per stage. NETZSCH manufactures all components to a high degree of accuracy and tight tolerances to provide consistent performance for extended service life and minimum maintenance.

People Also Ask

Send Your Enquiry :