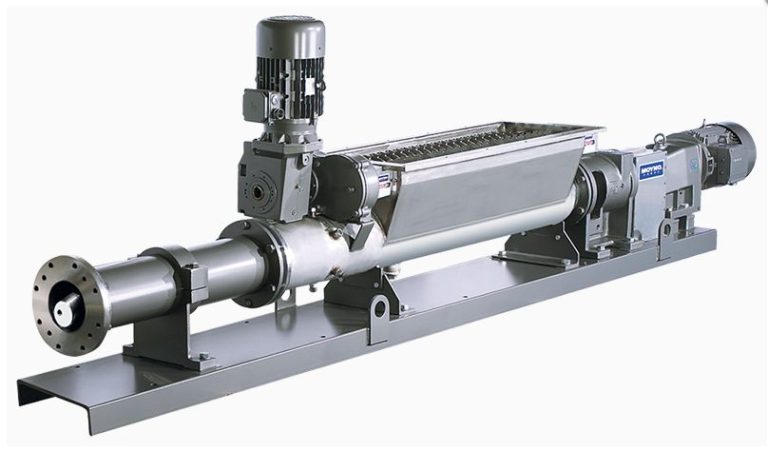

NEMO® BF Wastewater Pump

The NEMO® BF Wastewater Pump is a progressive cavity pump designed for handling high-viscosity fluids with solids or fibrous materials without clogging. It features a block-free design and patented FSIP® technology for easy maintenance and cleaning. This pump offers excellent flow rates and pressure capabilities, making it an ideal choice for various wastewater applications.

The description of NEMO® BF Wastewater Pump

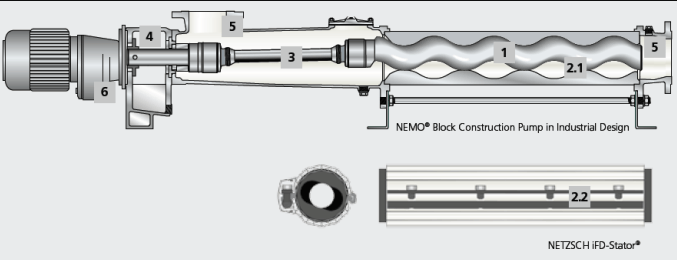

The Netzsch NEMO progressive cavity pump is used in all branches of industry for continuous, pressure-stable, gentle and low-pulsation conveyance as well as for dosing in proportion to speed, especially of highly viscous, compacted and crumbly media that do not tend to bridge. For optimum product feed into the conveying elements, the pump housing is designed with an enlarged, rectangular feed hopper and conical force-feed chamber as well as a special coupling rod with patented, positioned conveying screw. This also ensures the smooth conveying of solids containing shear-sensitive, abrasive, adhesive, thixotropic or dilatant as well as lubricating and non-lubricating materials. The NEMO® BF is particularly compact and economical in block construction with flanged drive.

The application of NEMO® BF Wastewater Pump

The NEMO® BF Wastewater Pump is commonly used in various wastewater applications, including sewage treatment plants, biogas plants, and industrial wastewater treatment facilities. Specifically, it can handle fluids with high viscosity and solids or fibrous materials without clogging, making it an ideal choice for pumping sludge, grit, and other challenging wastewater materials. The pump’s FSIP® technology also allows for easy maintenance and cleaning, which is critical in facilities where downtime needs to be minimized. Overall, the NEMO® BF Wastewater Pump offers reliable and efficient performance, making it a popular choice in the wastewater industry.

The feature of NEMO® BO/SO progressing cavity pump

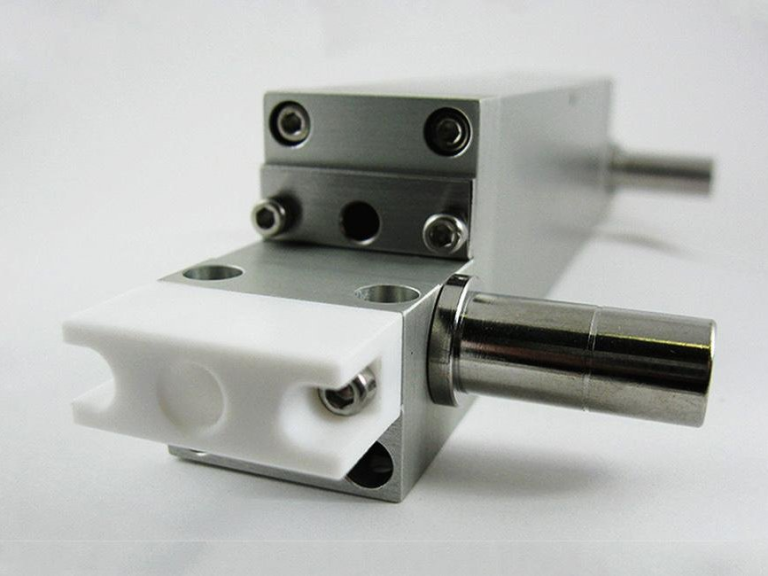

The progressing pump is a versatile and robust solution for a wide range of applications. Its unique design features an oversized joint and rotating unit, which minimizes stress and wear on the pump components, resulting in longer service life and reduced maintenance costs.

The pump’s optimized rotor/stator geometry allows it to handle various fluids, including abrasive and high-viscosity materials, with minimal shear or pulsation. Additionally, the NEMO® BO/SO boasts a blockage-free design and can handle solids, fibers, and other difficult-to-pump materials without clogging.

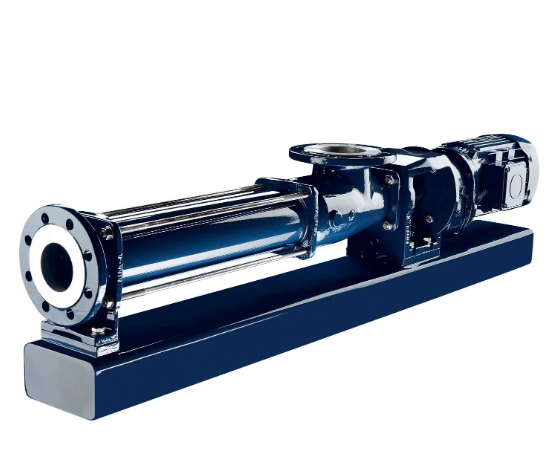

Other notable features of the NEMO® BO/SO include its low noise levels, compact footprint, and easy-to-maintain design. It can be equipped with various accessories, such as heating jackets and hopper feeders, to meet specific application requirements. Overall, the NEMO® BO/SO progressing cavity pump is a reliable and efficient solution for a wide range of industrial and municipal applications.

| Fluid | for wastewater, for chemicals, slurry, for food products |

| Operation | with electric motor |

| Technology | progressive cavity |

| Mobility | stationary |

| Domain | industrial, for the chemical industry, for wastewater treatment, for the food industry, for methanizers |

| Applications | for transfer, metering, feed, conveying, proportional dosage |

| Fluid specification | for high-viscosity fluids |

| Other characteristics | compact, close-coupledcutter |

| Flow | Max.: 60 m³/h (2,118.88 ft³/h) Min.: 0 m³/h (0 ft³/h) |

| Pressure | Max.: 36 bar (522.136 psi) Min.: 0 bar (0 psi) |

People Also Ask