[wpseo_breadcrumb]

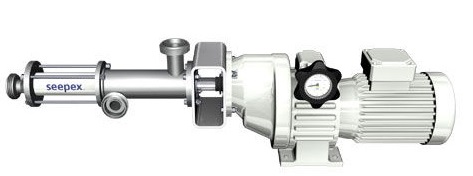

NEMO® Multiphase Progressing Cavity Pump

NEMO® Multiphase Progressing Cavity Pump maximum profitability and simultaneous conservation of resources:With NEMO Multiphase progressing cavity pumps, you increase oil and gas production efficiency despite declining oil field quality. In this way, you prevent a premature shutdown of low-pressure wells.

The description of NEMO® Multiphase Progressing Cavity Pump

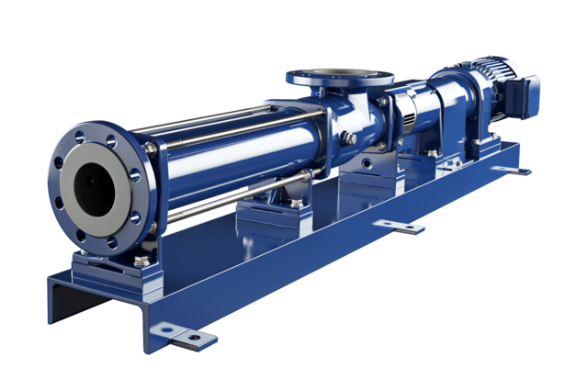

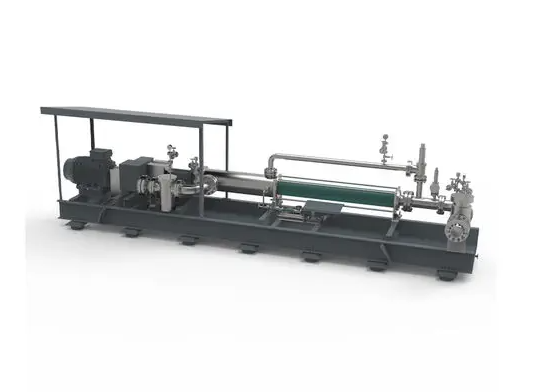

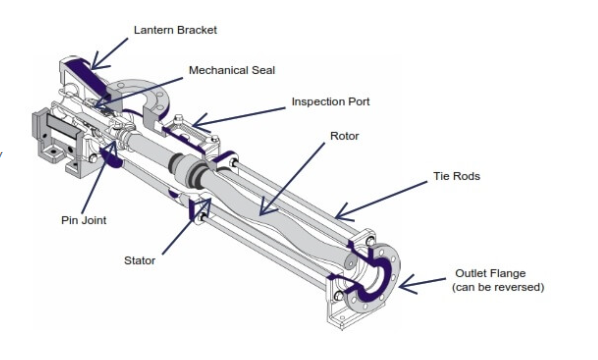

NEMO® Multiphase Progressing Cavity Pumps are particularly suitable for oil fields where mixtures with high water or sand content in the medium are being pumped. The unique design means that neither space-intensive separators at the wellhead nor separate pumps, compressors and pipelines are necessary to transport gas and liquid to the central collection stations. As the name suggests, prior phase separation is unnecessary with multiphase pumps. The progressive pumps are also certified to the highest standards so that safe pumping of low- to high-viscosity or shear-sensitive media or media with a high solids content is no problem.

Versatile Pumping Solution for Multiphase Fluids: NETZSCH NEMO® Progressing Cavity Pump

The NETZSCH NEMO® Multiphase Progressing Cavity Pump is a versatile pumping solution for the transfer of multiphase fluids with high gas volume fractions or solids content. It finds application in the oil and gas industry for wellhead production, pipeline transfer, and artificial lift systems, as well as other industries such as wastewater treatment, food processing, and chemical processing. Its ability to handle a wide range of viscosities and abrasive fluids makes it an ideal choice for various applications.

Features of NETZSCH NEMO® Multiphase Progressing Cavity Pump

The NETZSCH NEMO® Multiphase Progressing Cavity Pump is a versatile pumping solution designed to handle a wide range of fluids with varying viscosities, solids content, and gas fractions. Its key features include high efficiency, low pulsation, self-priming capabilities, and the ability to handle abrasive and shear-sensitive materials. The pump’s compact design and ease of maintenance also make it a popular choice in many industries including wastewater treatment, chemical processing, and oil and gas production.

People Also Ask

Send Your Enquiry :