[wpseo_breadcrumb]

Parameters

- Voltage: 380V

- Pump shaft position: side vertical

- Material: stainless steel

- Working pressure: 1.2MPa

- Flow rate: 0.6m³/h

- Drive mode: electric

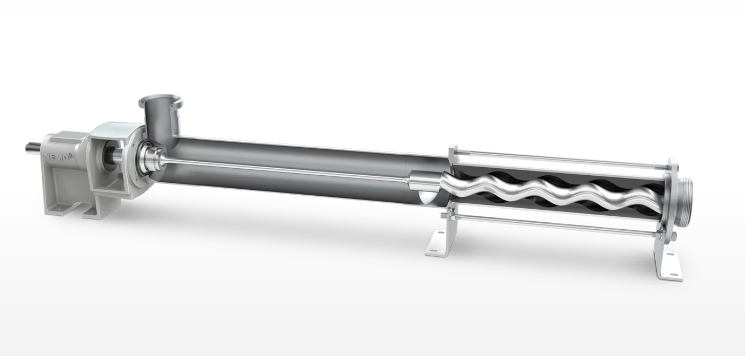

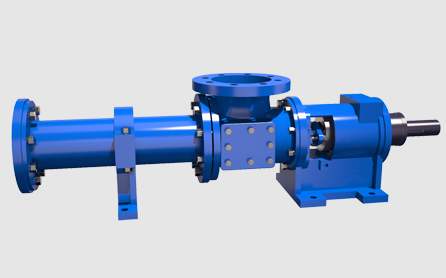

- Model: BN5-12

- Performance: variable frequency

- Lift: 120m

- Impeller structure: single impeller

- Number of impellers: 1

- Impeller suction mode: single suction

- Speed: 200RPM

- Application: metering pump

- Pressure: 1.2Mpa

- Brand: SEEPEX

Technical features: reliable and durable

The technical features of seepex BN5-12L include:

- Long service life: BN5-12L is made of high-quality materials, the stator and rotor are highly wear-resistant and have a long service life.

- High working pressure: seepex BN5-12L can cope with various high-pressure application scenarios.

- Wide flow range: meet the needs of different scenarios.

- Low energy consumption: Precision design and optimized hydraulic channels ensure low energy consumption.

- Low vibration and noise: Excellent dynamic balance design ensures low vibration and noise.

- Simple maintenance: Compact structure, few parts, easy maintenance.

Wide application areas

Chemical industry: seepex BN5-12L can be used to transport various chemicals, fats, spices and other liquids. Especially suitable for fluids with high viscosity and particles.

Food industry: seepex BN5-12L can be used to transport high-viscosity food raw materials such as dairy products, syrups, juices, pastes, etc. It can avoid product damage and contamination.

Pharmaceutical industry: seepex BN5-12L can be used to transport various medicines, creams, gels, etc. Since the pump body has no dead corners, it is conducive to cleaning and sterilization.

Environmental protection field: seepex BN5-12L can be used to transport semi-solid materials such as biogas and sludge.

It can also be used for various slurry transportation in wastewater treatment.

Mining and mining industry: seepex BN5-12L is suitable for transporting ore slurry and slurry containing abrasive particles.

Power industry: seepex BN5-12L can be used to transport boiler ash slurry, desulfurization slurry, etc.

BN5-12L has excellent self-priming, anti-fouling, wear resistance and other characteristics, and performs well in the transportation process of various liquids and semi-solid media. Widely used in various fields of industrial production.

Advantages: strong adaptability and excellent performance

Compared with other types of pumps, seepex BN5-12L has the following main advantages:

Strong adaptability: seepex BN5-12L can transport various viscous and solid particle-containing media and has a wide range of applications.

Strong wear resistance: BN5-12L stator and BN5-12L rotor are made of high-quality materials and have a long service life.

High reliability: Precision design and strict quality control ensure the reliable operation of the pump.

Simple maintenance: Compact structure, few parts, easy maintenance.

Energy saving and environmental protection: Hydraulic channel optimization, low energy consumption, more environmentally friendly and energy-saving.

people also ask

Send Your Enquiry :