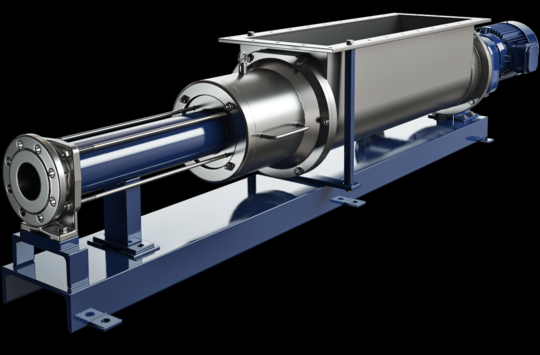

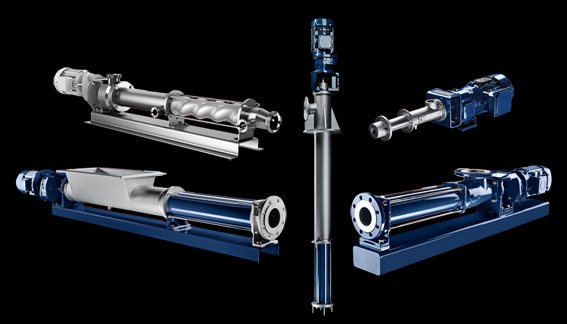

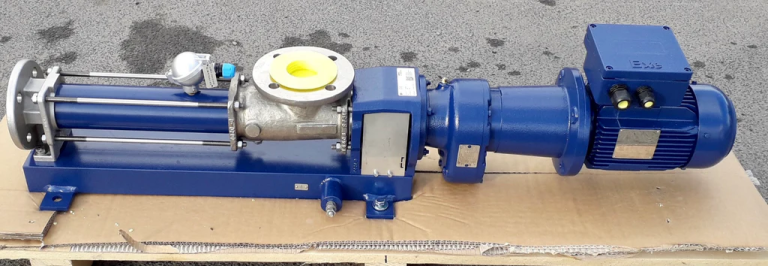

BN15-6L seepex BN

1. Performance Advantages 1.1 High Efficiency The seepex BN15-6L is recognized for its remarkable pumping efficiency. Compared to traditional centrifugal pumps, the BN15-6L operates with higher efficiency when handling high-viscosity liquids. This capability enables it to reduce energy consumption in continuous operation environments, ultimately saving operational costs for businesses. 1.2 Stability and Reliability In industrial…