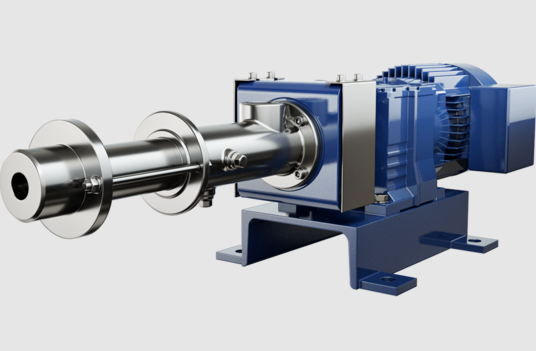

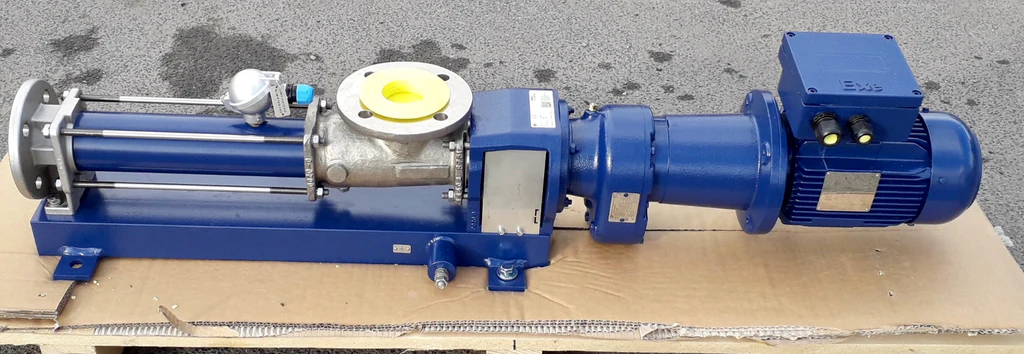

Parameters

| Performance: Non-blocking | Material: Fluorine-lined |

| Drive: Electric | Flow: 51 m3/h |

| Suction diameter: 150 mm | Discharge diameter: 150 mm |

| Speed: 230 rpm | Lift: 120 m |

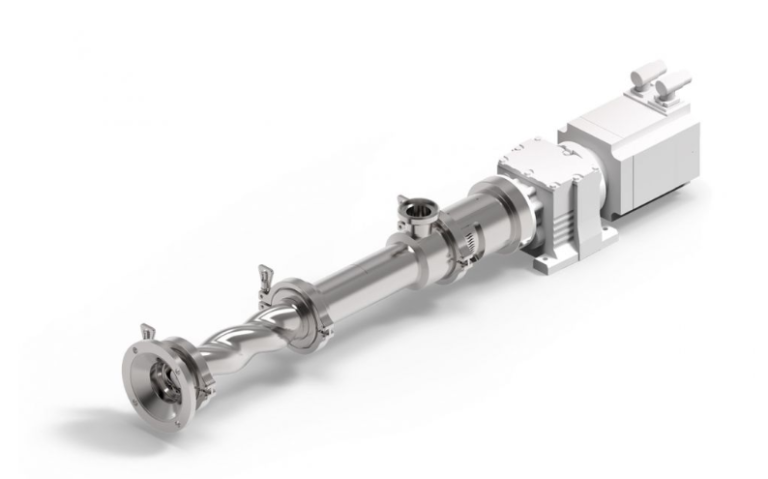

| Model: BN1-12L | Brand: seepex |

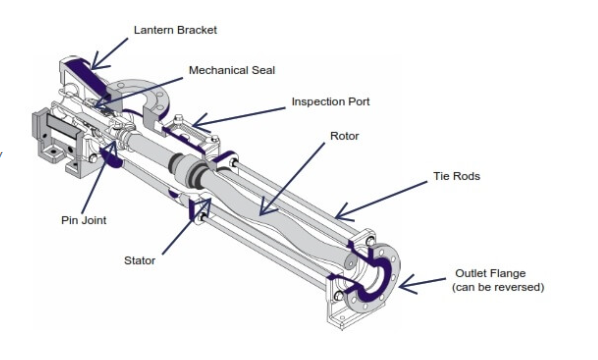

Through precise manufacturing processes, BN1-12L Stator ensures high-precision fit. Such a design not only improves the efficiency of the pump, but also reduces energy consumption, making the overall system more economical and environmentally friendly.

Seepex uses high-quality materials to ensure the durability and corrosion resistance of the rotor when manufacturing the BN1-12L rotor. The use of this material allows the rotor to maintain stable performance in a variety of harsh environments.

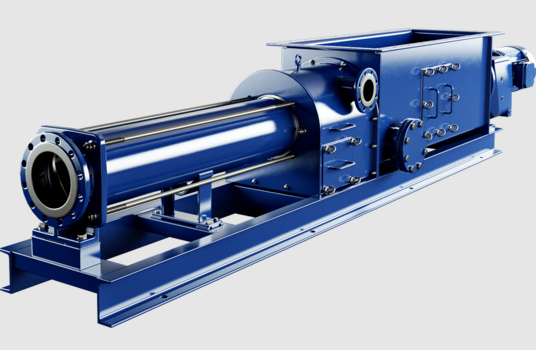

Main features

- High efficiency

The Seepex BN1-12L is designed to maximize the efficiency of the pump. Its fluid dynamics allow the pump to achieve high flow output with low energy consumption. This high efficiency not only reduces production costs, but also reduces environmental impact.

- Strong adaptability

The pump is capable of handling a variety of fluids of different properties, including high-viscosity liquids and fluids containing solid particles. Its flexible design enables it to adapt to different working conditions and meet various industrial needs.

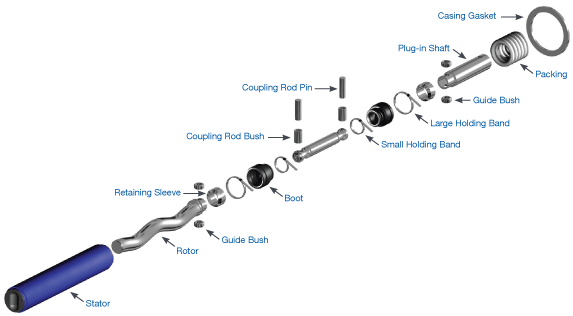

- Easy maintenance

The Seepex BN1-12L focuses on user-friendly design, and the maintenance process is simple and convenient. Regular inspection and maintenance can ensure the long-term stable operation of the pump, reduce downtime and improve production efficiency.

- Durability

The use of high-quality materials makes the Seepex BN1-12L have excellent durability. Whether in harsh working environments or under high pressure conditions, the pump can maintain good performance.

Application areas

BN1-12L has demonstrated its wide range of applications in multiple industries, mainly including:

- Chemical industry

In chemical production, it is often necessary to handle various viscous liquids and chemical media. With its excellent performance, BN1-12L can safely and stably transport liquids.

- Food industry

In the food processing process, there are extremely high requirements for hygiene and safety. BN1-12L uses food-grade materials, meets relevant standards, and can meet the strict requirements of the food industry.

- Pharmaceutical industry

The media in the pharmaceutical process often have high viscosity and specific chemical properties. The design concept of BN1-12L enables it to smoothly handle these special media and ensure product quality.

- Environmental Protection Industry

BN1-12L also plays a key role in sewage treatment and waste management. Its strong conveying capacity and corrosion resistance make it an important equipment in the environmental protection industry.

Reasons to choose Seepex BN1-12L

The reason to choose Seepex BN1-12L pump is not only its excellent performance, but also the multiple advantages it brings. Here are some key points:

- Cost-effectiveness

Due to its high efficiency, Seepex BN1-12L can reduce energy consumption while improving production efficiency, thus saving costs for enterprises.

- Reliability

After rigorous testing, the pump performs well under various working conditions, greatly improving production reliability.

- Flexibility

Suitable for the conveying of a variety of fluids, making it an ideal choice for enterprises in multiple industries.

- Environmental Protection

The low energy consumption and high efficiency design help enterprises reduce their carbon footprint and meet the goal of sustainable development.

Maintenance and Care

In order to ensure the long-term stable operation of BN1-12L, regular maintenance and care are essential. Here are some maintenance suggestions:

Regular inspection: Check the various parts of the pump regularly to ensure that there is no wear or damage.

Cleaning maintenance: Keep the pump body and the surrounding environment clean to prevent impurities from affecting the operation of the pump.

Lubrication maintenance: Lubricate regularly to ensure smooth operation of all moving parts.

Monitor operating status: Use monitoring equipment to monitor the operating status of the pump in real time and detect potential problems in time.

people also ask

Send Your Enquiry :