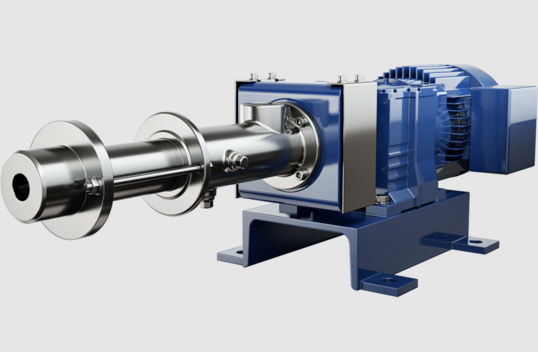

Features of BN1-12L Stator

Its design concept combines advanced material science and engineering technology to ensure reliability and durability under various working conditions.

- Material selection

BN1-12L Stator uses high-quality materials that have excellent corrosion resistance and wear resistance. This makes the product particularly suitable for handling various chemical media and prolongs its service life.

- Precision manufacturing

Through precise manufacturing processes, BN1-12L Stator ensures high-precision fit. Such a design not only improves the efficiency of the pump, but also reduces energy consumption, making the overall system more economical and environmentally friendly.

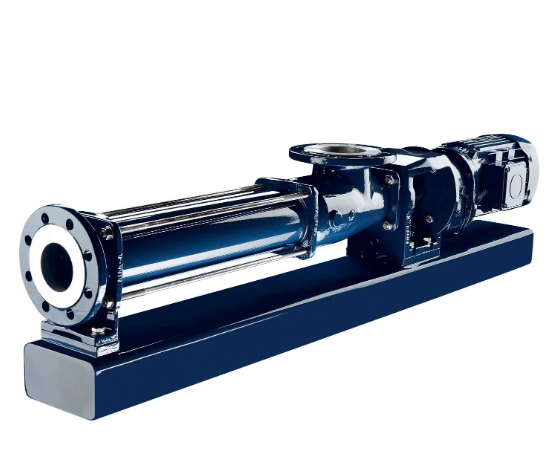

- Strong adaptability

BN1-12L Stator has good adaptability and can work stably under different temperatures and pressures. Whether in high-temperature and high-pressure industrial environments or in low-temperature and low-pressure application scenarios, BN1-12L can maintain excellent performance.

Application areas

- Chemical industry

In the chemical industry, BN1-12L stators are often used to transport various chemicals, including acids, alkalis and solvents. Its corrosion resistance enables it to safely handle these challenging fluids.

- Food and Beverage

The food and beverage industry has extremely high requirements for the hygiene and safety of equipment. The material and design of the BN1-12L stator meet relevant standards, which can effectively prevent cross contamination and ensure product safety.

- Pharmaceutical Industry

In the pharmaceutical field, the BN1-12L stator is used to deliver drugs and biologics. Its precise delivery capacity and reliable performance provide a guarantee for the production of drugs.

Advantages of BN1-12L Stator

Companies using BN1-12L Stator can obtain multiple advantages, which make it unique in the market.

- Improved efficiency

The design of BN1-12L Stator can significantly improve the working efficiency of the pump. Its excellent fluid dynamics reduce the resistance of the fluid, thereby improving the overall delivery capacity.

- Reduced maintenance costs

Due to the durability and low wear characteristics of BN1-12L Stator, users have greatly reduced costs in maintenance and replacement. Long-term stable operation means less downtime and lower maintenance frequency.

- Environmental protection and energy saving

In today’s context of emphasizing sustainable development, the high efficiency and low energy consumption of BN1-12L Stator make it an ideal choice for environmentally friendly enterprises. Using this product can effectively reduce energy consumption and reduce carbon footprint.

Maintenance and care

- Regular inspection

In order to ensure the best performance of the BN1-12L stator, regular inspection is essential. The inspection content includes the wear of seals, looseness of connecting parts, etc. Problems should be dealt with in time to avoid more serious failures.

- Cleaning

After using the stator for a period of time, some dirt and residue may accumulate. Regularly cleaning the inside of the stator can not only improve its working efficiency, but also extend its service life. Use appropriate cleaning agents and tools to ensure that the cleaning process does not damage the stator.

- Lubrication and maintenance

Proper lubrication can reduce friction and reduce wear. Add lubricating oil or grease regularly according to the usage to ensure the smooth operation of each moving part.

people also ask

Send Your Enquiry :