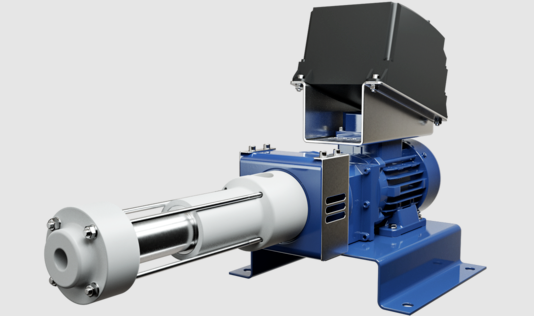

Design features of the BN1-12L rotor

- Optimized rotor shape

The BN1-12L rotor adopts a unique spiral design, which not only improves the fluid delivery efficiency, but also reduces the shear force of the fluid in the pump. This enables the rotor to perform well when handling viscous liquids, especially in the food and chemical industries.

- Material selection

Seepex uses high-quality materials to ensure the durability and corrosion resistance of the rotor when manufacturing the BN1-12L rotor. The use of this material allows the rotor to maintain stable performance in a variety of harsh environments.

- Precision process

The production process of the BN1-12L rotor uses advanced processing technology to ensure that the size of each rotor is accurate and reliable. This precision manufacturing process not only improves the service life of the rotor, but also reduces maintenance costs.

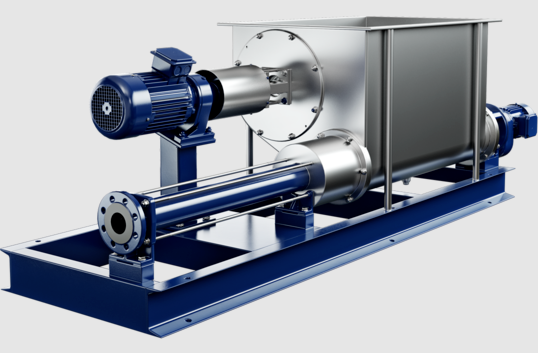

Application areas of BN1-12L rotor

- Chemical industry

In the chemical industry, the BN1-12L rotor is widely used in the delivery of various chemicals. Its corrosion resistance enables it to safely and effectively handle a variety of chemical media, ensuring the safety and stability of the production process.

- Food and Beverage Industry

The food and beverage industry has extremely high requirements for the hygiene standards of equipment. The BN1-12L rotor uses materials that meet food safety standards to ensure that food will not be contaminated during the conveying process. This feature makes it an ideal choice for this industry.

- Pharmaceutical Industry

In the pharmaceutical industry, the precision design and high efficiency of the BN1-12L rotor enable it to deliver drugs in a strict hygienic environment. Its high temperature and corrosion resistance meet the high requirements for equipment in the pharmaceutical process.

Advantages of the BN1-12L rotor

- High efficiency

When conveying fluids, the BN1-12L rotor can maintain a stable flow and pressure, greatly improving work efficiency.

- Low maintenance cost

Due to the use of high-quality materials and precise craftsmanship, the BN1-12L rotor has a low failure rate, which reduces the frequency of maintenance and replacement and reduces the operating costs of the enterprise.

- Flexibility

The BN1-12L rotor can be customized according to different working conditions to meet the needs of different customers. This flexibility makes it more competitive in the market.

Use and Maintenance

- Installation Precautions

When installing the BN1-12L rotor, ensure that the pump body is clean to prevent impurities from affecting the operation of the rotor. At the same time, follow the manufacturer’s instructions for installation to ensure the normal operation of the equipment.

- Regular Inspection

Regularly inspect the rotor, pay attention to wear and operating conditions, and perform maintenance in time to effectively extend the service life of the rotor.

- Cleaning and Maintenance

When handling food or other liquids with high hygiene requirements, clean the rotor regularly to ensure that it remains in good working condition.

people also ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com