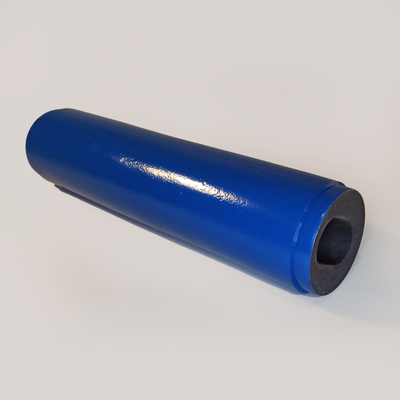

BN15-6L stator seepex

Characteristics of the BN15-6L Stator 1. High Efficiency The BN15-6L stator utilizes advanced materials and design, enabling it to maintain high efficiency under various working conditions. Its structure is meticulously designed to ensure smooth fluid flow, thereby reducing energy loss. 2. Wear Resistance This stator boasts excellent wear resistance, capable of withstanding prolonged use without…