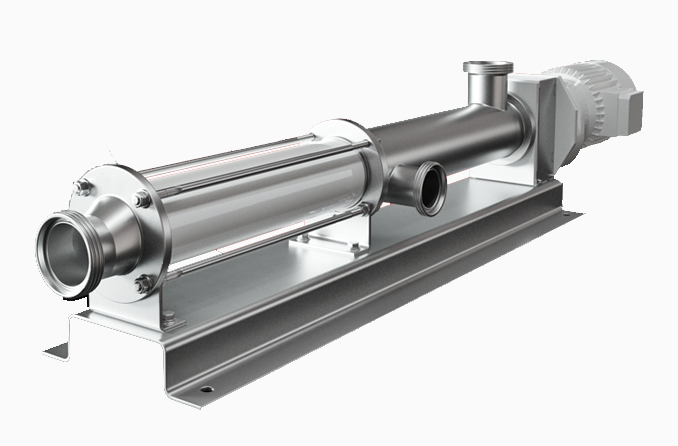

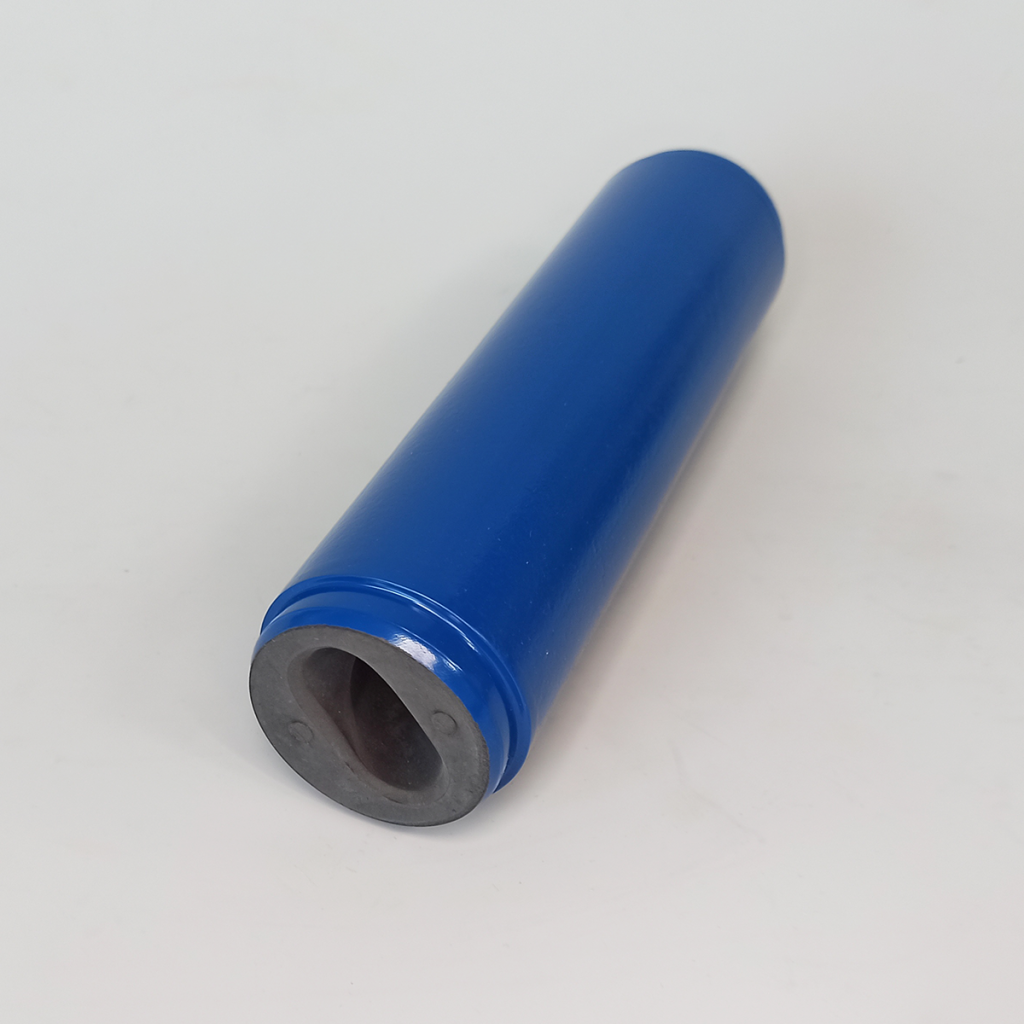

Main features of MD003-12 stator

- High efficiency

The MD003-12 stator uses advanced materials and processes to ensure that it can provide stable performance under various working conditions. Its fluid dynamic design significantly improves the efficiency of the stator and can effectively reduce energy consumption.

- Wear resistance

The surface of the stator has been specially treated to have excellent wear resistance. This means that the MD003-12 stator can still maintain good working condition under long-term operation and extend its service life.

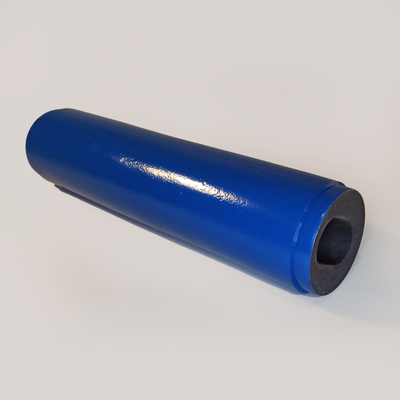

- Strong adaptability

The MD003-12 stator can adapt to a variety of fluids, including viscous liquids and fluids containing solid particles. This makes it perform well in different industrial applications and can meet diverse needs.

- Easy to install and maintain

The stator is designed with user convenience in mind, with a simple installation process and a long maintenance cycle. Regular inspection and cleaning can ensure the best performance of the stator and reduce the risk of unexpected downtime.

Application areas of MD003-12 Stator

MD003-12 Stator is widely used in many industries. Here are some of the main application areas:

- Food and beverage industry: In the food processing process, MD003-12 Stator can ensure the safety and purity of the fluid and meet strict hygiene standards.

- Oil and gas industry: In oil extraction and transportation, MD003-12 Stator can effectively handle various viscous fluids to ensure the smooth progress of the production process.

- Chemical industry: In chemical production, this Stator can withstand the erosion of various chemicals to ensure the long-term stable operation of the equipment.

- Environmental protection industry: In sewage treatment and waste management, MD003-12 Stator can effectively treat various sewage and help enterprises achieve environmental protection goals.

Maintenance of MD003-12 stator

In order to ensure the long-term stable operation of MD003-12 stator, regular maintenance is essential. Here are some maintenance methods:

- Regular inspection

Regularly check the appearance and connection parts of the stator to ensure that there is no looseness or damage. Especially when running under high load, more attention should be paid to observation.

- Cleaning work

Keep the stator clean to avoid the accumulation of dirt and impurities. This can not only improve work efficiency, but also reduce wear.

- Lubrication maintenance

Regularly check and replenish the lubrication system of the stator to ensure the quality and quantity of lubricating oil to reduce friction and extend the service life of the stator.

- Replace parts in time

Once some parts of the stator are found to be worn or faulty, they should be replaced in time. Delayed replacement may cause more serious damage and economic losses.

people also ask

Send Your Enquiry :