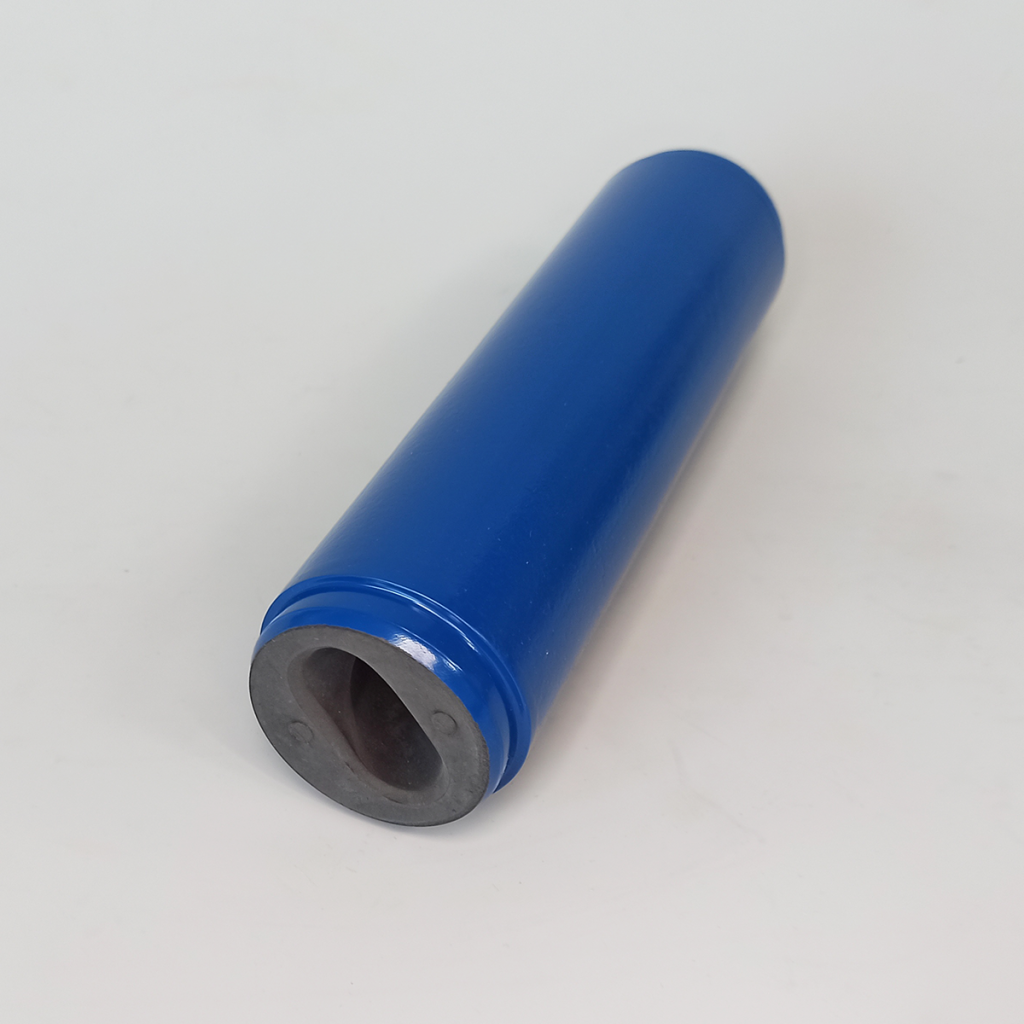

Features of BN05-12 Stator

Design and Materials

BN05-12 Stator uses high-quality materials to ensure its durability and stability under various working conditions. Its unique design improves the working efficiency of the pump and can adapt to different fluid characteristics.

High efficiency

The stator has excellent fluid conveying capacity and can achieve efficient fluid movement with low energy consumption. This high efficiency not only reduces operating costs, but also improves the economy of the entire system.

Strong adaptability

BN05-12 Stator can handle a variety of fluids, including viscous liquids and fluids containing solid particles. This adaptability makes it widely used in many fields such as chemical industry, food processing and municipal engineering.

Application fields of Seepex BN05-12 Stator

Seepex BN05-12 Stator is widely used in many fields. The following are some of the main applications:

- Chemical industry

In the chemical industry, the pump conveying medium is usually corrosive and viscous. BN05-12 Stator has become an indispensable equipment in chemical production due to its corrosion resistance.

- Food Processing

The food industry places high demands on the hygiene and safety of equipment. Seepex pumps are designed with these factors in mind to ensure that no contamination is generated during food processing.

- Water Treatment

In the field of water treatment, the BN05-12 Stator can efficiently transport sewage and other wastewater. Its design allows it to maintain good performance when dealing with complex water quality.

Maintenance and Care

- Regular Inspection

Regular inspection of the BN05-12 Stator is the key to ensuring its long-term stable operation. It is recommended to regularly check the seals, connections and surface wear.

- Cleaning and Maintenance

Keeping the stator clean can effectively extend its service life. Use appropriate cleaning agents and tools to avoid damage to the stator surface.

- Timely Replacement

When the stator is found to be obviously worn or faulty, it should be replaced in time to avoid affecting the operating efficiency of the entire pump. Choosing original accessories can better guarantee the performance of the equipment.

people also ask

Send Your Enquiry :