[wpseo_breadcrumb]

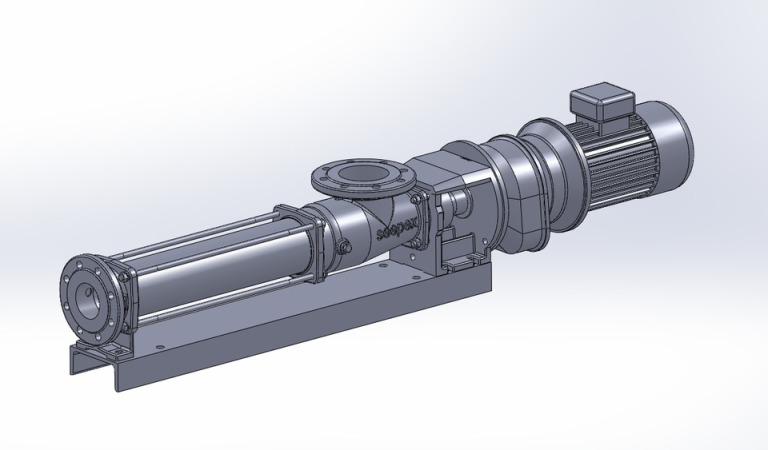

Introduction to Seepex

Seepex is a company specializing in the manufacture of pumps and conveying systems. With its superior technology and innovative design, Seepex has earned a good reputation in the global market.

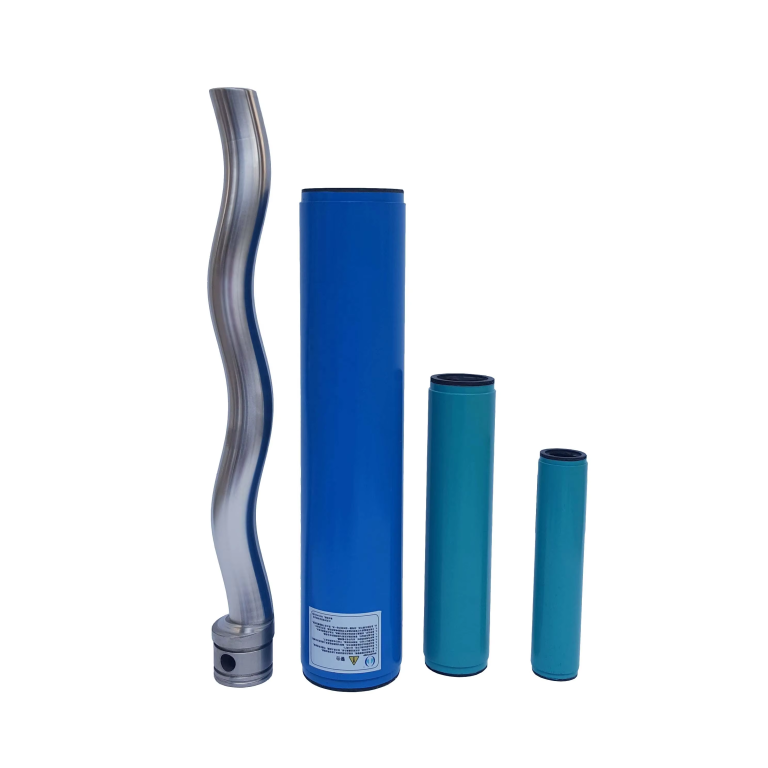

Features of BN75-6L rotor

- High efficiency

The design of the BN75-6L rotor takes into account the optimization of fluid dynamics, which can achieve efficient fluid delivery at low energy consumption. This enables it to significantly reduce operating costs during long-term operation.

- Superior wear resistance

The rotor is made of high-quality materials and has good wear resistance and corrosion resistance. This enables the BN75-6L rotor to maintain a long service life in harsh working environments.

- Strong adaptability

The BN75-6L rotor is suitable for a variety of fluids, including viscous and solid-containing fluids. It is designed to handle the flow characteristics of different fluids and meet different industrial needs.

- Low-noise operation

The rotor generates low noise during operation, which can effectively improve the working environment and reduce the impact on operators.

Application fields

3.1 Food and beverage industry

In the food and beverage industry, hygiene and safety are the primary considerations. The BN75-6L rotor has a good hygienic design and is suitable for the transportation of liquids such as milk and juice to ensure that the product quality is not affected.

3.2 Chemical industry

In the chemical industry, many fluids are corrosive and highly viscous. With its corrosion-resistant materials and strong conveying capacity, the BN75-6L rotor has become an indispensable equipment in chemical production.

3.3 Water treatment

In the water treatment process, the BN75-6L rotor can be used for the transportation and treatment of sewage, helping to achieve efficient water treatment goals and ensure the rational use of water resources.

Maintenance of BN75-6L rotor

In order to ensure the long-term stable operation of the BN75-6L rotor, regular maintenance and maintenance are essential. Here are some maintenance suggestions:

- Regular inspection

Check the rotor regularly to ensure that there are no signs of wear or damage. Timely detection of problems can avoid greater losses.

- Cleaning and maintenance

During use, keep the rotor clean to avoid the accumulation of impurities that affect performance. Use a special cleaning agent to clean the rotor surface.

- Lubrication and maintenance

According to the instructions for use, add lubricating oil to the rotor regularly to ensure smooth operation and reduce wear.

- Temperature monitoring

Monitor the operating temperature of the rotor to avoid overheating. Excessive temperature will affect the service life and performance of the rotor.

people also ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com