[wpseo_breadcrumb]

What is Seepex BN75-6L?

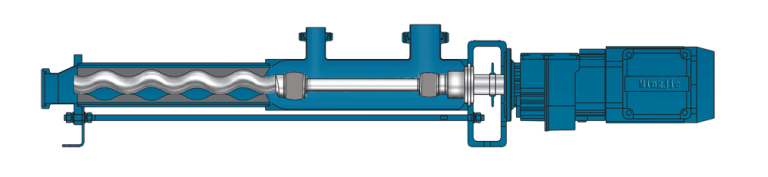

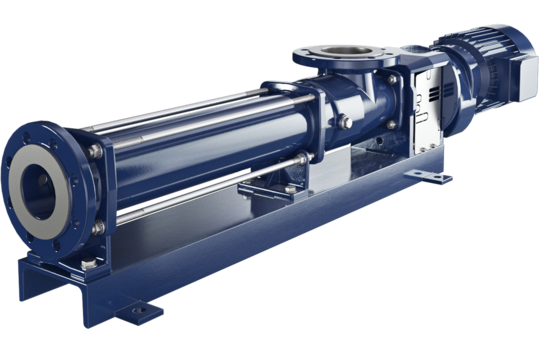

Seepex BN75-6L is a technologically advanced screw pump designed for conveying viscous fluids and media containing solid particles. The pump uses the principle of a screw pump to push the fluid to the discharge end through a rotating screw. It has a simple structure and is easy to maintain, making it suitable for a variety of industrial environments.

Parameters

| Pump shaft position: Horizontal | Power: 11kW |

| Conveying medium: Sewage pump, impurity pump | Weight: 200kg |

| Performance: Wear-resistant | Output flow: 200 |

| Drive mode: Electric | Efficiency: 98% |

| Brand: SEEPEX | Discharge diameter: DN125 (mm) |

| Suction diameter: DN125 (mm) | Model: BN75-6L |

| Speed: 273 (rpm) | Material: Cast iron |

| Lift: 60m | Application: Chemical pump |

| Flow rate: 12-70 (m3/h) | Working temperature: Normal temperature |

| Number of impellers: Single stage | Shaft power: 11 |

The design of the BN75-6L stator fully considers the principles of fluid dynamics and uses high-quality materials to ensure stability and durability under various working conditions. Its compact structure and strong adaptability can meet the needs of different industries.

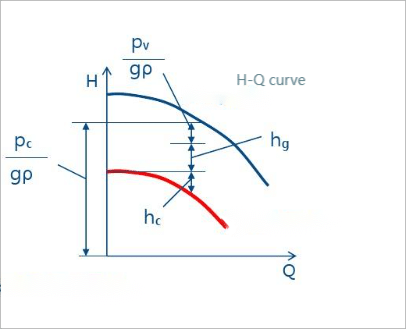

The core of the BN75-6L rotor lies in its innovative screw design. This design not only improves the conveying efficiency, but also reduces energy consumption. The close cooperation between the rotor and the stator ensures the smooth flow of the fluid in the pump, thereby reducing turbulence and vibration.

Main features of Seepex BN75-6L

- Versatility

The pump is suitable for a variety of fluids, including viscous liquids, slurries and media containing solid particles. This versatility makes it have good application prospects in different industrial fields. - High efficiency

The Seepex BN75-6L pump exhibits excellent efficiency when conveying viscous fluids. Its unique screw design ensures continuous fluid delivery and reduces fluid shear and loss. - Corrosion-resistant materials

This model of pump uses corrosion-resistant materials and can operate stably in various harsh environments. This makes it widely used in fields such as chemical industry, food processing and sewage treatment. - Easy maintenance

The design of Seepex BN75-6L makes maintenance work simple. Users can easily disassemble and replace wearing parts, reducing maintenance costs and downtime.

Advantages of Seepex BN75-6L

Choosing Seepex BN75-6L screw pump is not only because of its advanced technology, but also because of its many advantages in practical applications:

Energy saving

Due to its efficient fluid delivery capacity, Seepex BN75-6L can ensure stable fluid delivery while reducing energy consumption.Reduce maintenance frequency

The durable design of the pump reduces the failure rate of the equipment, and users do not have to perform frequent maintenance, saving time and costs.Good compatibility

Seepex BN75-6L is compatible with a variety of industrial standard equipment, which is convenient for users to integrate the system.Simple operation

The equipment has a friendly operating interface and is easy to use, even non-professionals can quickly master it.

Application areas

Seepex BN75-6L screw pumps are widely used in many industries. Here are some typical application areas:

- Food and beverage industry

Applicable to handling various fluids, including juices, condiments, etc., to ensure the hygiene and safety of the products. - Chemical industry

Can effectively transport various chemicals to meet different process requirements. - Environmental protection industry

In sewage treatment and wastewater management, Seepex BN75-6L performs well and helps companies achieve environmental protection goals. - Pharmaceutical industry

When handling drugs and biological products, the accuracy and reliability of the pump are crucial, and Seepex BN75-6L can meet these requirements.

Precautions for using BN75-6L

When using Seepex BN75-6L pumps, users need to pay attention to the following points to ensure the normal operation of the pump and extend its service life:

Regular inspection: Check the operating status of the pump regularly to detect potential problems in time.

Keep clean: Ensure that the pump inlet and outlet and the surrounding environment are kept clean to prevent impurities from entering.

Proper lubrication: Lubricate the moving parts of the pump regularly to reduce wear.

Follow the operating procedures: Strictly follow the operating manual provided by the manufacturer to avoid damage caused by improper use.

people also ask

Send Your Enquiry :