Material selection

Corrosion-resistant materials

The material selection of the BN130-12L rotor is very particular, and usually uses a corrosion-resistant alloy material. This material can not only resist the erosion of chemical substances, but also operate stably under high temperature and high pressure environments, extending the service life of the equipment.

Balance of strength and toughness

In terms of material selection, the BN130-12L rotor also focuses on the balance between strength and toughness. High-strength materials can withstand greater mechanical pressure, while toughness ensures that the rotor will not break easily in unexpected situations, thereby improving the safety of the equipment.

Features of BN130-12L Rotor

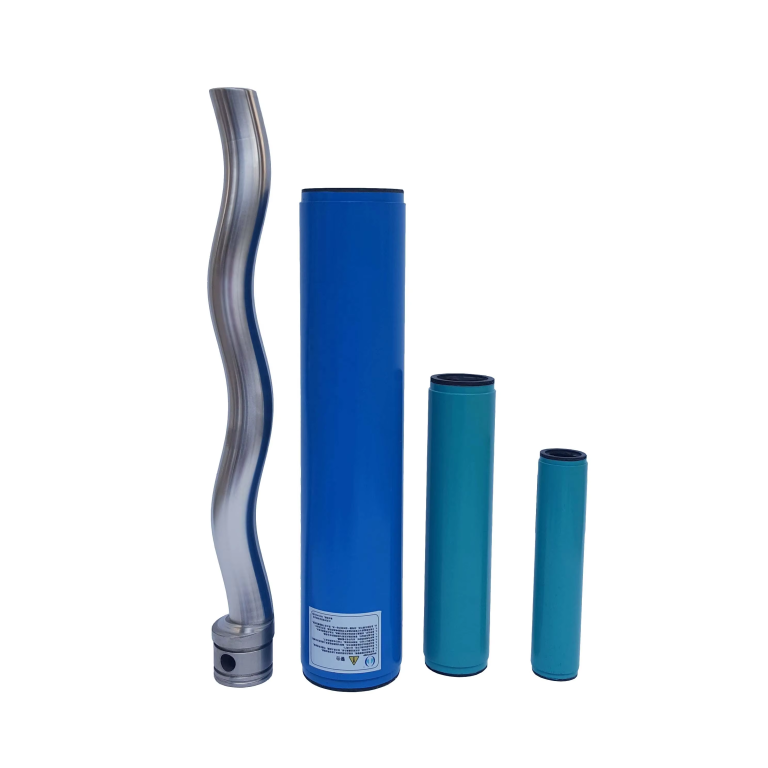

The BN130-12L rotor is a rotor designed by Seepex to meet stringent industrial needs. Its main features include:

High durability

The rotor is made of high-quality materials, has excellent corrosion resistance and wear resistance, and can operate stably for a long time in harsh environments.

High efficiency

The design of this rotor optimizes the fluid delivery efficiency, reduces energy consumption, and ensures the economy and efficiency of the system.

Easy maintenance

The structural design of the BN130-12L rotor allows for easy disassembly and maintenance, reducing downtime and increasing equipment availability.

Strong adaptability

The rotor can operate under a variety of operating conditions and is suitable for different types of media, such as viscous liquids and solid particle suspensions.

Application areas

The BN130-12L rotor is widely used in a variety of industries, including:

- Food and beverage industry

In this industry, the rotor is mainly used to transport various liquids, such as juice, syrup and dairy products, to ensure product quality and hygiene. - Chemical industry

The BN130-12L rotor can handle a variety of chemical media and is suitable for transportation and mixing in chemical reaction processes. - Wastewater treatment

In wastewater treatment plants, the rotor is used to transport sewage and sludge, helping to achieve effective water resource recovery and environmental protection. - Pharmaceutical industry

In the pharmaceutical industry, the rotor is used to transport various drugs and chemicals to ensure the safety and accuracy of the production process.

Advantages of BN130-12L Rotor

The advantages of choosing BN130-12L rotor are obvious, mainly including:

- Improve production efficiency

Due to its high-efficiency design, BN130-12L rotor can significantly improve the fluid conveying efficiency in the production process, thereby improving overall production efficiency. - Reduce operating costs

The high durability and low energy consumption characteristics of this rotor can effectively reduce the maintenance and operating costs of equipment, helping companies achieve a higher return on investment. - Improve product quality

In industries with extremely high quality requirements such as food and pharmaceuticals, BN130-12L rotor can ensure the safety and hygiene of the conveying process, thereby improving the quality of the final product. - Flexibility and adaptability

This rotor is suitable for a variety of fluids and working conditions, and companies can flexibly adjust according to actual needs to reduce investment risks.

Maintenance and care

Regular inspection

In order to ensure the normal operation of the BN130-12L rotor, regular inspection is essential. The inspection content includes the wear of the rotor, the integrity of the seals, and the state of the lubricating oil. Through regular inspections, potential problems can be discovered and solved in a timely manner.Cleaning and maintenance

In the chemical, food and pharmaceutical industries, rotor cleaning is particularly important. Using appropriate cleaning agents and tools to clean the rotor regularly can not only extend its service life, but also ensure the hygiene of the production process.Replace worn parts in time

With the increase of usage time, some parts of the BN130-12L rotor may wear out. Replacing these worn parts in time can effectively prevent failures and ensure the efficient operation of the equipment.

people also ask

Fill up and submit the below inquiry form, or directly write us an email: info@pumpvv.com