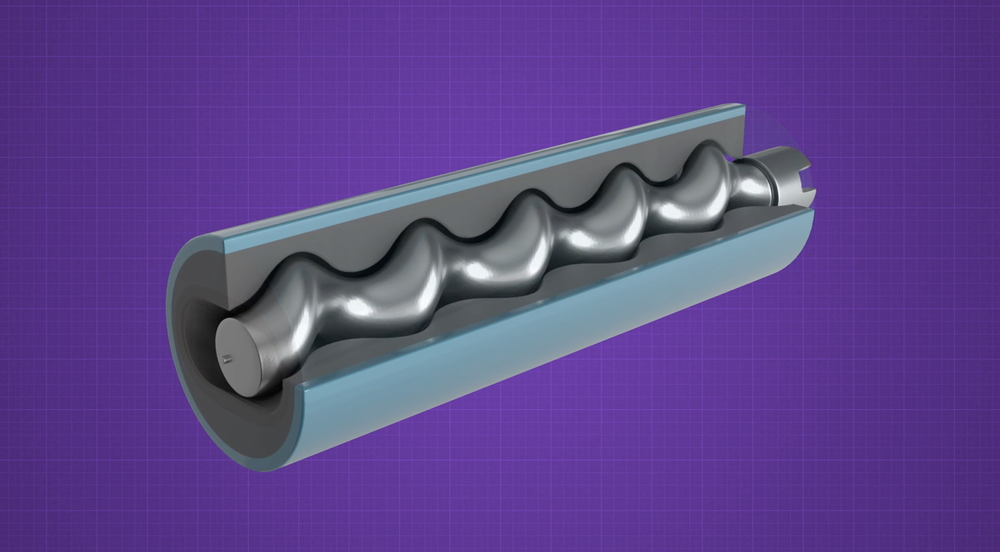

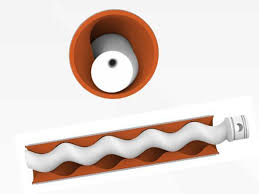

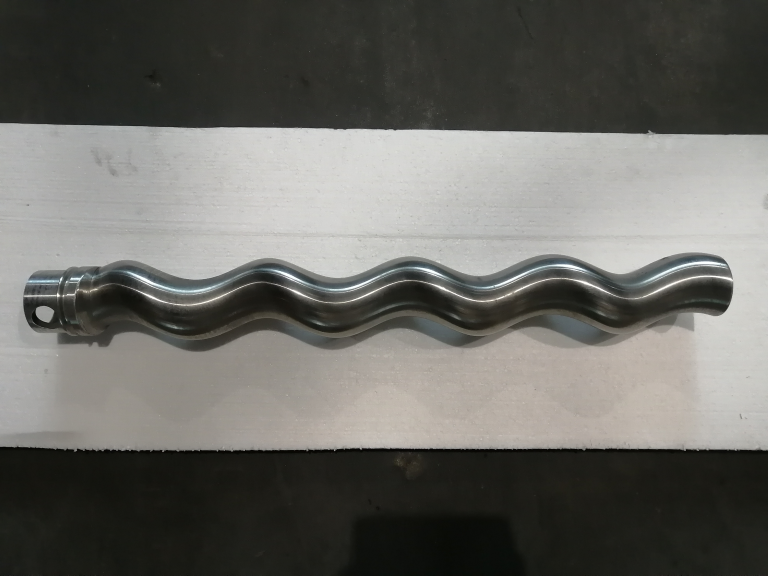

MD003-12 rotor Seepex

Features of Seepex MD003-12 rotor The Seepex MD003-12 rotor adopts advanced design concepts and has the following significant features: The MD003-12 rotor performs well in fluid transportation, can effectively reduce energy consumption and improve work efficiency. This feature enables it to perform well in long-term operation and reduce the operating costs of enterprises. The rotor…