BN100-6L rotor seepex

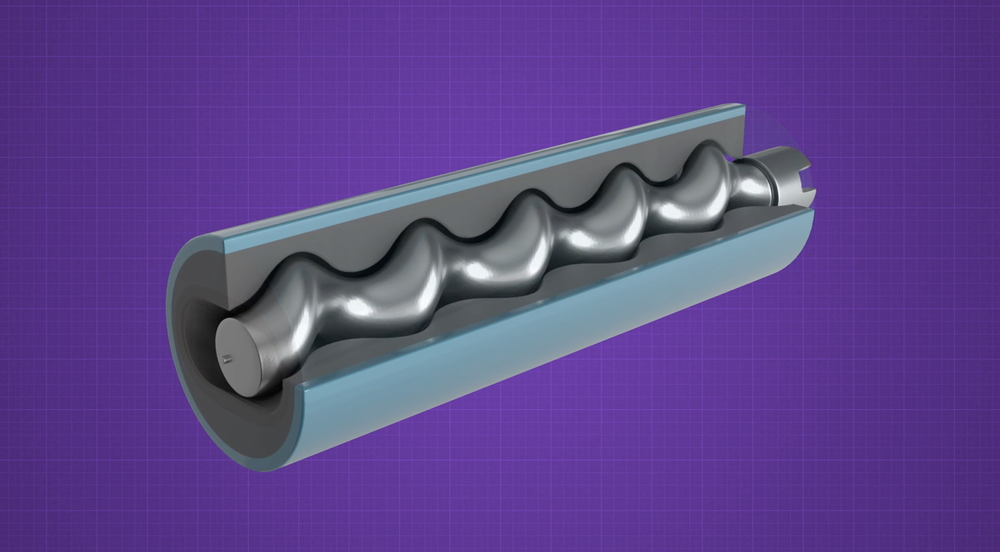

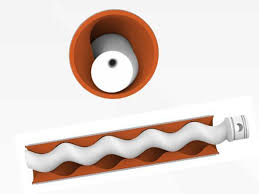

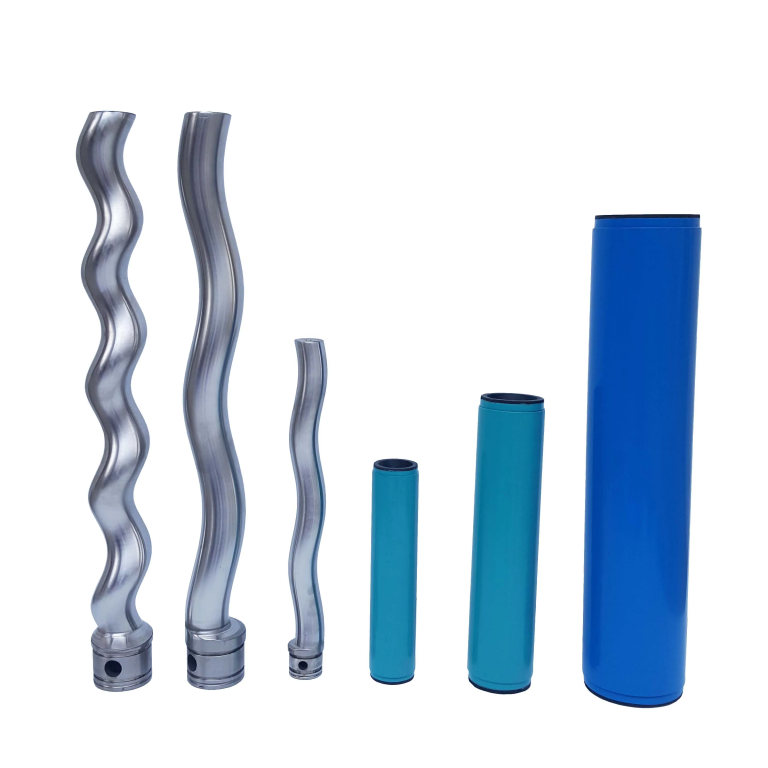

Structural features of Seepex BN100-6L Rotor The Seepex BN100-6L rotor is made of high-strength materials to ensure stable operation under high pressure and high temperature. Its specially designed spiral shape allows the fluid to form a low-shear flow during the conveying process, avoiding damage to the fluid properties, and is particularly suitable for conveying fragile…