Advantages

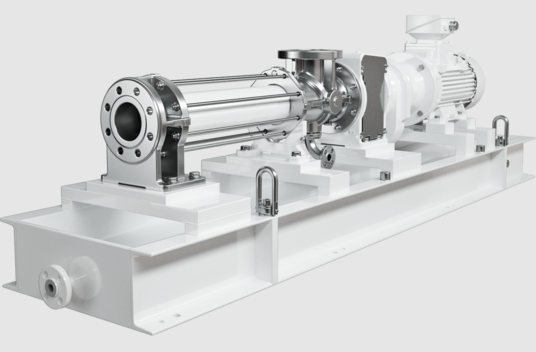

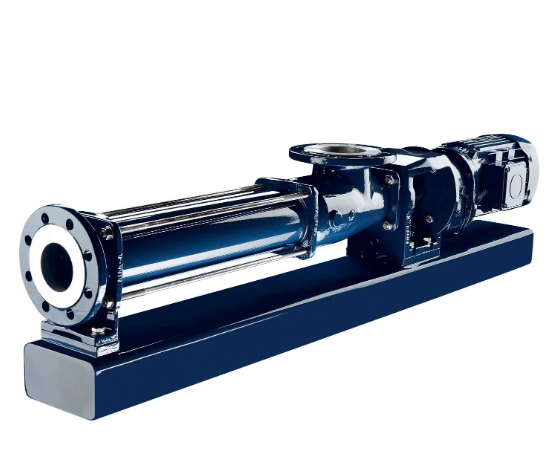

First, the design of the seepex BN15-6LT rotor takes full account of wear resistance and corrosion resistance. Made of high-strength materials, the rotor can resist erosion and wear from various industrial media and ensure stable operation under high temperature and high pressure. This makes it very suitable for use in industries such as chemical, petroleum and sewage treatment, and can effectively extend the service life of the equipment.

Second, the rotor has excellent self-priming ability and can easily handle various viscous fluids. This makes it perform well in industries such as food processing, chemical and sewage treatment. Whether it is conveying viscous food fluids or treating sewage containing particles, the seepex BN15-6LT rotor can complete the task efficiently and stably. This greatly improves production efficiency and reduces the complexity of manual operation.

In addition, in terms of maintenance, the seepex BN15-6LT rotor is simple in design and easy to inspect and replace. Users can quickly perform routine maintenance and reduce downtime. This efficient maintenance feature ensures that the equipment is always in the best working condition and improves overall production efficiency.

Application areas

- Chemical industry

- In the chemical production process, the seepex BN15-6LT rotor can effectively handle various corrosive and viscous liquids, ensuring the stability and safety of product delivery.

- Food and beverage industry

- This rotor meets hygiene standards and is very suitable for the delivery of food and beverages, ensuring the safety of fluids during the treatment process and avoiding contamination.

- Wastewater treatment

- In sewage treatment plants, the seepex BN15-6LT rotor can efficiently transport wastewater and sludge containing solid particles to ensure treatment efficiency.

people also ask

Send Your Enquiry :