Advantages

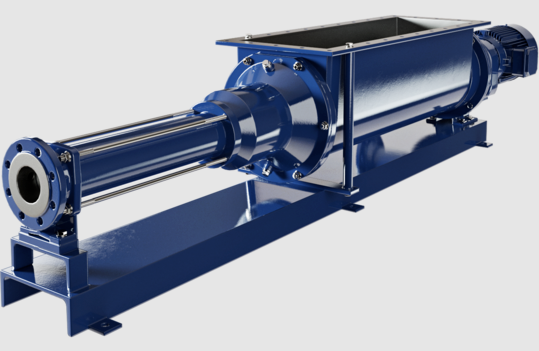

The material selection of the seepex BN10-6L rotor is very particular. It uses high-strength and wear-resistant materials to ensure stable operation under high pressure and temperature environments. This feature enables it to handle a variety of corrosive fluids, especially in the chemical industry. Users can rely on the long-term stability of the rotor under harsh conditions, reducing the frequency of maintenance and replacement, thereby effectively saving operating costs.

The rotor has excellent self-priming ability and can easily handle fluids containing solid particles and high viscosity. This makes the seepex BN10-6L rotor outstanding in food processing, pharmaceutical industry and sewage treatment. As industrial production has higher requirements for fluid transportation, this powerful function makes it an important tool for enterprises to improve production efficiency.

Easy maintenance is another major advantage of the seepex BN10-6L rotor. Its modular design allows users to quickly perform daily inspections and replacements, significantly reducing equipment downtime and improving overall production efficiency.

Application areas

In the food and beverage industry, the hygienic design of the seepex BN10-6L rotor is very important. It complies with international hygiene standards, ensures that the fluid is not contaminated during transportation, and meets strict food safety requirements. This is essential to ensure product quality and consumer health.

In the field of sewage treatment, the seepex BN10-6L rotor also plays an important role. It can efficiently transport sewage and sludge, ensuring a smooth and efficient sewage treatment process. Its stable performance allows operators to improve the efficiency of the entire treatment system and contribute to environmental protection.

Features

- High Wear Resistance

Made from premium materials, it effectively resists wear, extending its lifespan. - Superior Self-Priming Capability

Efficiently handles viscous and solid-laden fluids, offering strong adaptability. - Corrosion Resistance

Suitable for various corrosive media, ensuring stability in chemical and food industries. - Compliance with Hygiene Standards

Designed to meet international hygiene standards, ensuring safe fluid transport and preventing contamination. - Modular Design

Facilitates easy maintenance and replacement, reducing downtime and improving production efficiency. - Smooth Flow

Minimizes cavitation and vibration during operation, ensuring stable fluid transport.

people also ask

Send Your Enquiry :