Aftermarket Moyno Pump Parts: Cost-effective replacements for reliable pump maintenance

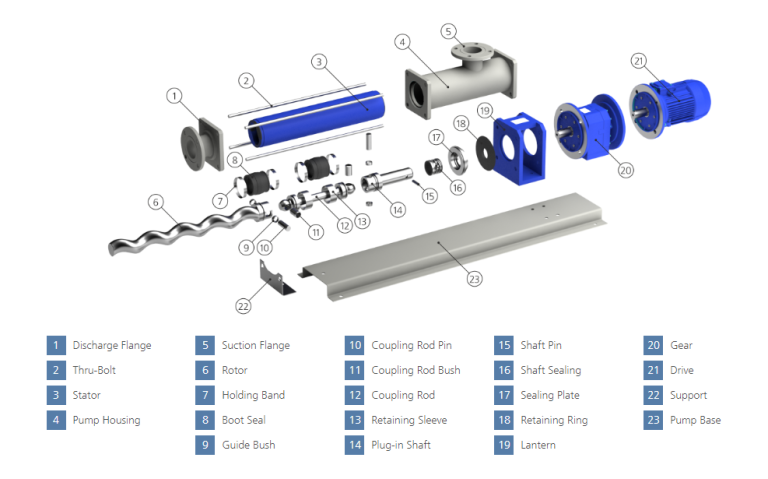

Aftermarket Moyno Pump Parts refer to replacement components and accessories available for Moyno pumps that are manufactured by third-party companies. These parts are designed to meet or exceed the original equipment manufacturer (OEM) specifications and provide a cost-effective solution for maintaining and repairing Moyno pumps. They include various components like stators, rotors, seals, shafts, bearings, and other wear parts necessary for pump operation. By opting for aftermarket Moyno pump parts, users can ensure reliable performance and extend the lifespan of their pumps while reducing maintenance costs.

The Description of Aftermarket Moyno Pump Parts

Aftermarket Moyno Pump Parts refer to replacement components and accessories designed for Moyno pumps, which are progressive cavity pumps known for their efficient and reliable performance. These aftermarket parts are specifically manufactured as alternative options to the original Moyno pump parts, offering a cost-effective solution for repairing and maintaining Moyno pumps.

The Application of Aftermarket Moyno Pump Parts

Aftermarket Moyno Pump Parts can be utilized in various industries and applications where Moyno pumps are used. These pumps are commonly employed in sectors such as wastewater treatment, oil and gas, chemical processing, food and beverage, pharmaceuticals, mining, and many others. The aftermarket parts ensure that the Moyno pumps continue to operate optimally, promoting smooth fluid transfer and efficient pumping processes.

The Features of Aftermarket Moyno Pump Parts

- High-Quality Construction: Aftermarket Moyno Pump Parts are manufactured using top-grade materials to ensure durability, longevity, and consistent performance. They undergo rigorous quality control measures to meet or exceed industry standards.

- Precise Compatibility: These aftermarket parts are designed to fit seamlessly with Moyno pumps, offering precise compatibility and easy installation. They are engineered to match the specifications and dimensions of the original parts, ensuring proper functioning and reliable operation.

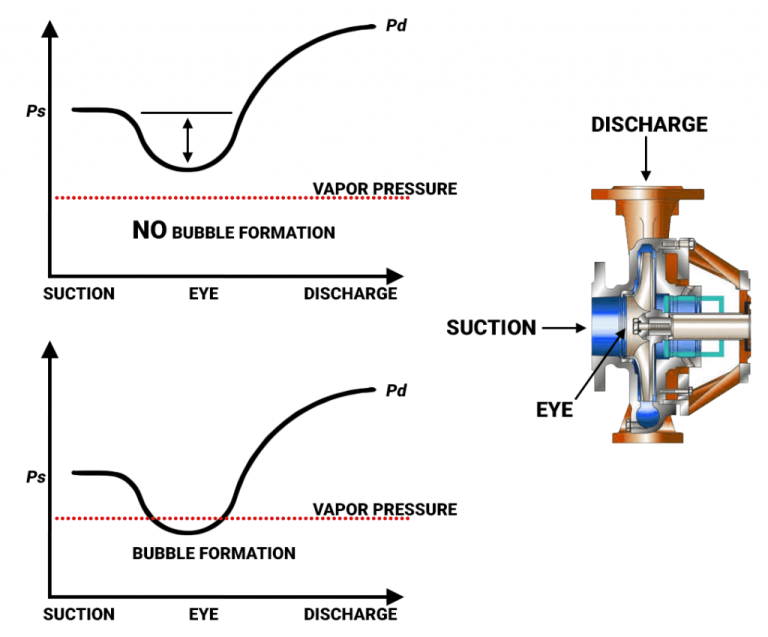

- Enhanced Efficiency: Aftermarket Moyno Pump Parts are engineered to deliver enhanced efficiency and performance. Whether it’s the stators, rotors, seals, bearings, or other components, these parts are crafted to promote smooth flow, reduce energy consumption, and improve overall pump efficiency.

- Cost-Effective Solution: Opting for aftermarket Moyno pump parts presents a cost-effective alternative to purchasing brand-new OEM (Original Equipment Manufacturer) parts. These aftermarket parts offer comparable quality and performance at a lower price point, allowing businesses to save on maintenance and repair costs.

- Wide Range of Options: Aftermarket Moyno Pump Parts are available in a wide range of options, catering to various model

Send Your Enquiry :